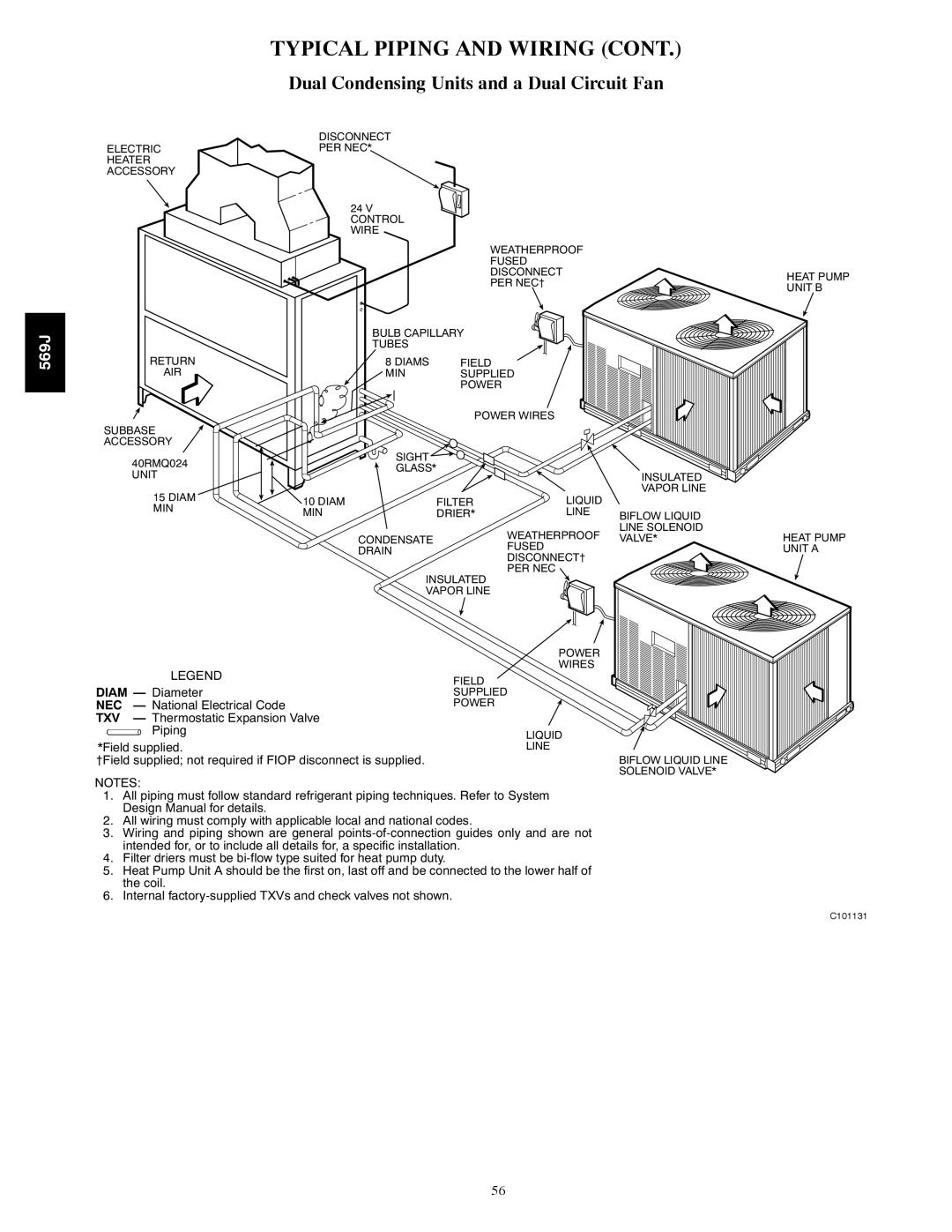

TYPICAL PIPING AND WIRING (CONT.)

Dual Condensing Units and a Dual Circuit Fan

569J

ELECTRIC

HEATER

ACCESSORY

RETURN

AIR

SUBBASE

ACCESSORY

40RMQ024

UNIT

15 DIAM MIN

DISCONNECT

PER NEC*

24 V CONTROL WIRE

| WEATHERPROOF | |

| FUSED |

|

| DISCONNECT |

|

| PER NEC† |

|

BULB CAPILLARY |

| |

TUBES |

|

|

8 DIAMS | FIELD |

|

MIN | SUPPLIED |

|

| POWER |

|

| POWER WIRES |

|

SIGHT |

|

|

GLASS* |

|

|

10 DIAM | FILTER | LIQUID |

MIN | DRIER* | LINE |

CONDENSATEWEATHERPROOF

DRAINFUSED

DISCONNECT†

PER NEC

INSULATED

VAPOR LINE

POWER

WIRES

INSULATED

VAPOR LINE

BIFLOW LIQUID LINE SOLENOID VALVE*

HEAT PUMP UNIT B

HEAT PUMP UNIT A

LEGEND | FIELD | |

DIAM — Diameter | ||

SUPPLIED | ||

NEC — National Electrical Code | POWER |

TXV — Thermostatic Expansion Valve

Piping | LIQUID |

*Field supplied. | LINE |

†Field supplied; not required if FIOP disconnect is supplied. |

|

BIFLOW LIQUID LINE SOLENOID VALVE*

NOTES:

1.All piping must follow standard refrigerant piping techniques. Refer to System Design Manual for details.

2.All wiring must comply with applicable local and national codes.

3.Wiring and piping shown are general

4.Filter driers must be

5.Heat Pump Unit A should be the first on, last off and be connected to the lower half of the coil.

6.Internal

C101131

56