OPERATING WITH FLOAT CONTROL

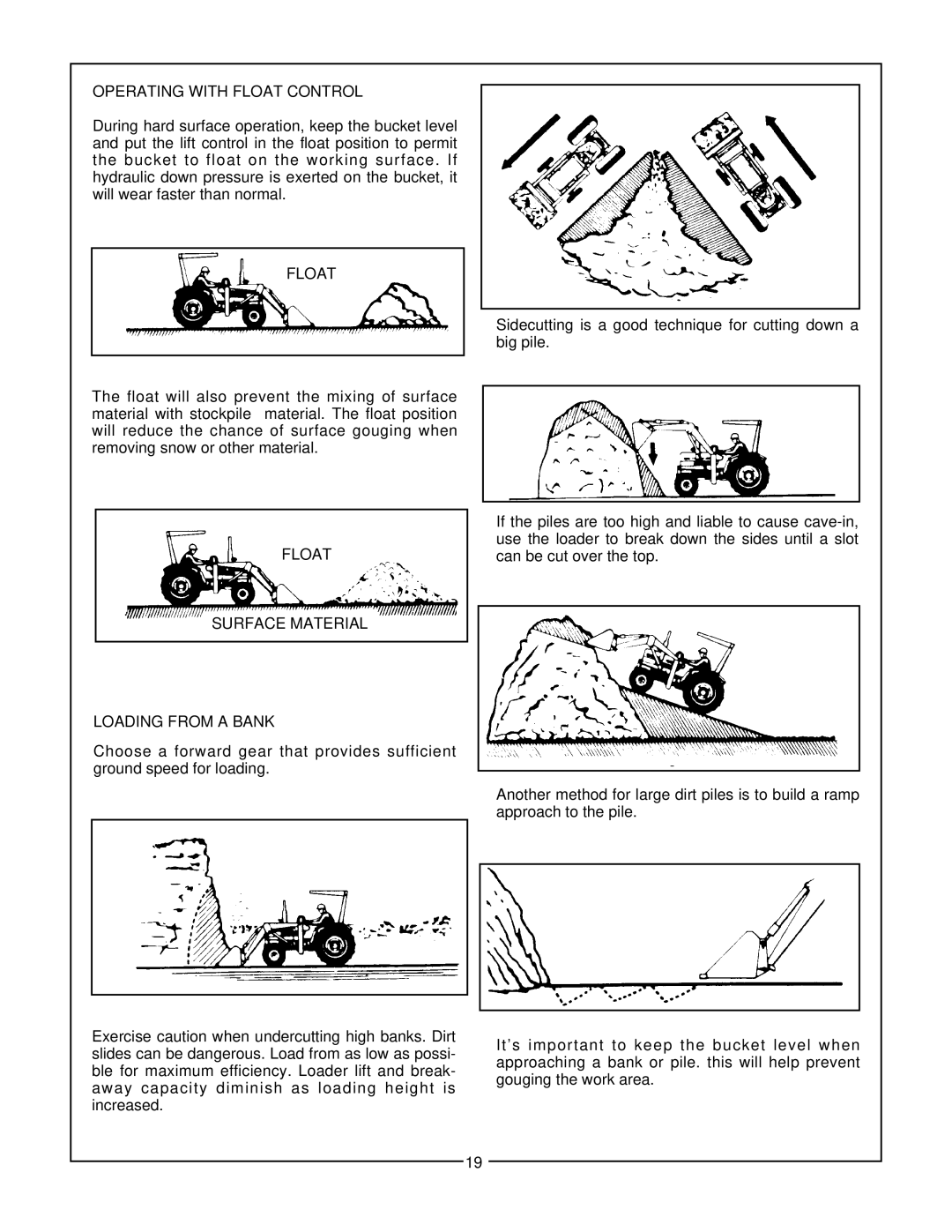

During hard surface operation, keep the bucket level and put the lift control in the float position to permit the bucket to float on the working surface. If hydraulic down pressure is exerted on the bucket, it will wear faster than normal.

FLOAT

The float will also prevent the mixing of surface material with stockpile material. The float position will reduce the chance of surface gouging when removing snow or other material.

Sidecutting is a good technique for cutting down a big pile.

FLOAT

SURFACE MATERIAL

LOADING FROM A BANK

Choose a forward gear that provides sufficient ground speed for loading.

Exercise caution when undercutting high banks. Dirt slides can be dangerous. Load from as low as possi- ble for maximum efficiency. Loader lift and break- away capacity diminish as loading height is increased.

If the piles are too high and liable to cause

Another method for large dirt piles is to build a ramp approach to the pile.

It’s important to keep the bucket level when approaching a bank or pile. this will help prevent gouging the work area.

19