Extend the attachment cylinders to lower loader sub- frames onto center mounting bracket tubes. Refer to Figure 2.

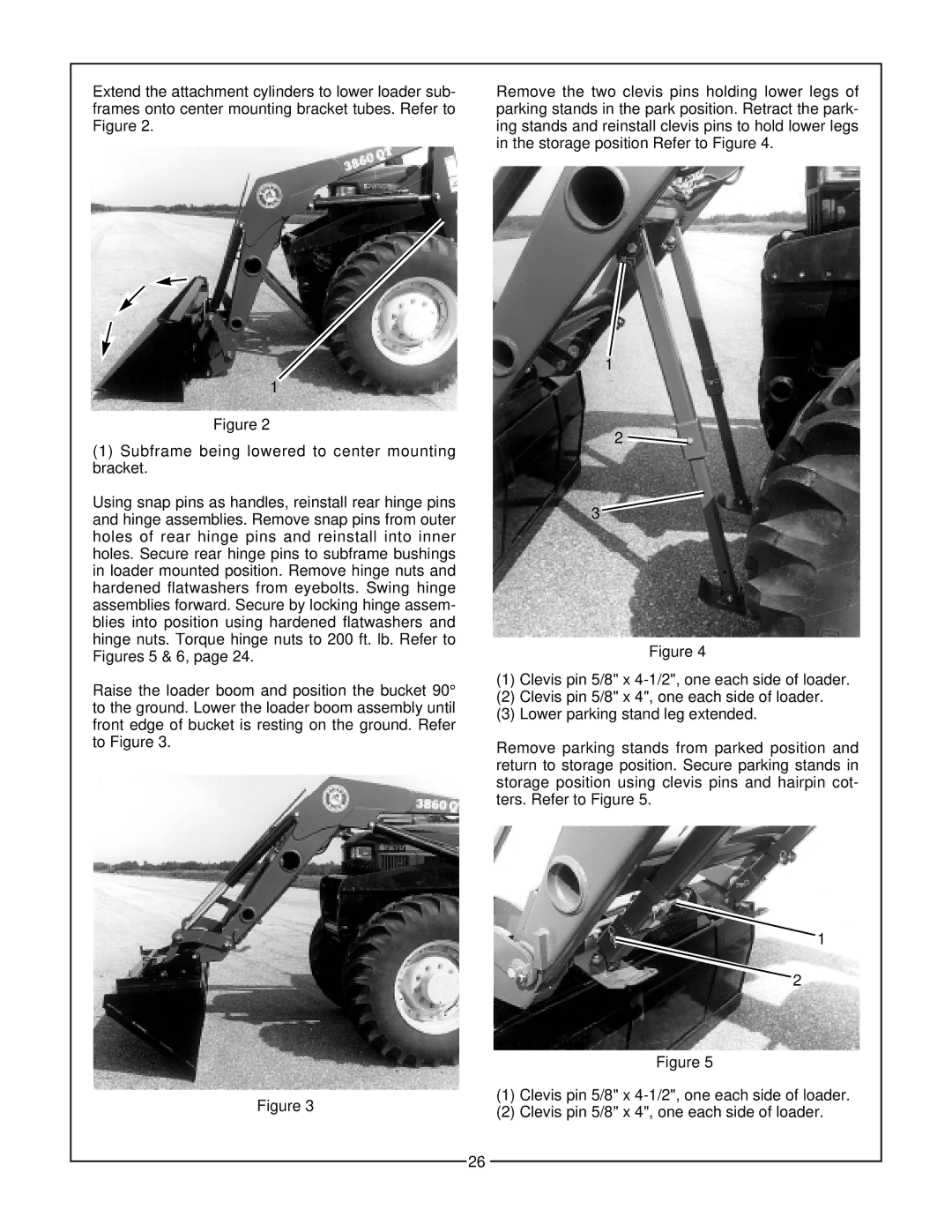

Remove the two clevis pins holding lower legs of parking stands in the park position. Retract the park- ing stands and reinstall clevis pins to hold lower legs in the storage position Refer to Figure 4.

1

Figure 2

(1)Subframe being lowered to center mounting bracket.

Using snap pins as handles, reinstall rear hinge pins and hinge assemblies. Remove snap pins from outer holes of rear hinge pins and reinstall into inner holes. Secure rear hinge pins to subframe bushings in loader mounted position. Remove hinge nuts and hardened flatwashers from eyebolts. Swing hinge assemblies forward. Secure by locking hinge assem- blies into position using hardened flatwashers and hinge nuts. Torque hinge nuts to 200 ft. lb. Refer to Figures 5 & 6, page 24.

Raise the loader boom and position the bucket 90° to the ground. Lower the loader boom assembly until front edge of bucket is resting on the ground. Refer to Figure 3.

Figure 3

1

2 ![]()

3

Figure 4

(1)Clevis pin 5/8" x

(2)Clevis pin 5/8" x 4", one each side of loader.

(3)Lower parking stand leg extended.

Remove parking stands from parked position and return to storage position. Secure parking stands in storage position using clevis pins and hairpin cot- ters. Refer to Figure 5.

1

2

Figure 5

(1)Clevis pin 5/8" x

(2)Clevis pin 5/8" x 4", one each side of loader.

26