Section 2. Installation and Hardware Set-Up

∙Electrical noise causing possible loss or corruption of serial data.

∙Electrical noise being transferred back to the datalogger causing errors on analogue measurements.

∙Long term damage in the form of corrosion caused by current flowing along

If it is not possible to prevent a ground loop, or if electrical noise is found to be a problem, it may be necessary to add an

Even if ground loops can be prevented, the length of cables that can be used for RS232 signals is limited to a few tens of metres (the exact length depending on the RS232 driver hardware and the cable used).

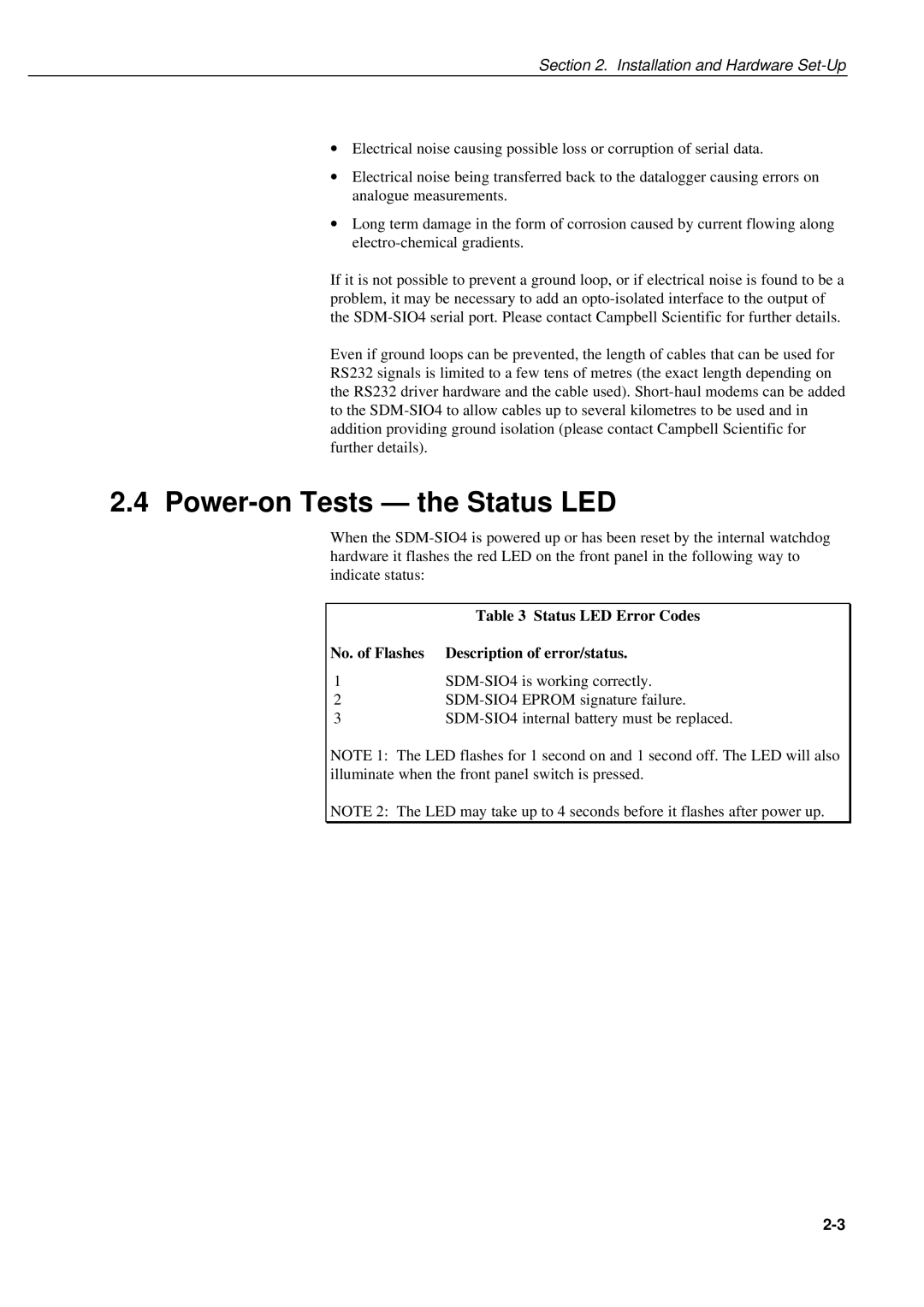

2.4 Power-on Tests — the Status LED

When the

| Table 3 Status LED Error Codes |

No. of Flashes | Description of error/status. |

1 | |

2 | |

3 |

NOTE 1: The LED flashes for 1 second on and 1 second off. The LED will also illuminate when the front panel switch is pressed.

NOTE 2: The LED may take up to 4 seconds before it flashes after power up.