TO REASSEMBLE ACTUATOR TO VALVE BODY:

All 2-way normally-open valves:

1.Push the valve stem completely down and close seat valve.

NOTE: It may be necessary to shut down the system pump to ensure valve stem is closed.

2.Loosen locknut and screw stem extension down fully on valve stem to adjust stem extension for proper closure.

3.Attach actuator to valve linkage mounting bracket and secure with self-tapping screws.

4.Make all necessary electrical connections.

5.Electrically power actuator by turning circuit breaker to ON. Turn HOA switch to OFF position. Perform the heat- ing coil valve quick test to stroke the actuator to its full extended position. See Example 26. Leave the unit in test mode and proceed to Step 6.

6.Screw the stem extension up until its hole aligns with the hole in the actuator piston.

7.Screw the stem extension 2 full turns farther up into the actuator piston.

8.While still in Quick Test, press  to retract actuator piston and align holes to insert connecting pin. Exit Quick Test.

to retract actuator piston and align holes to insert connecting pin. Exit Quick Test.

9.Tighten the locknut against the stem extension.

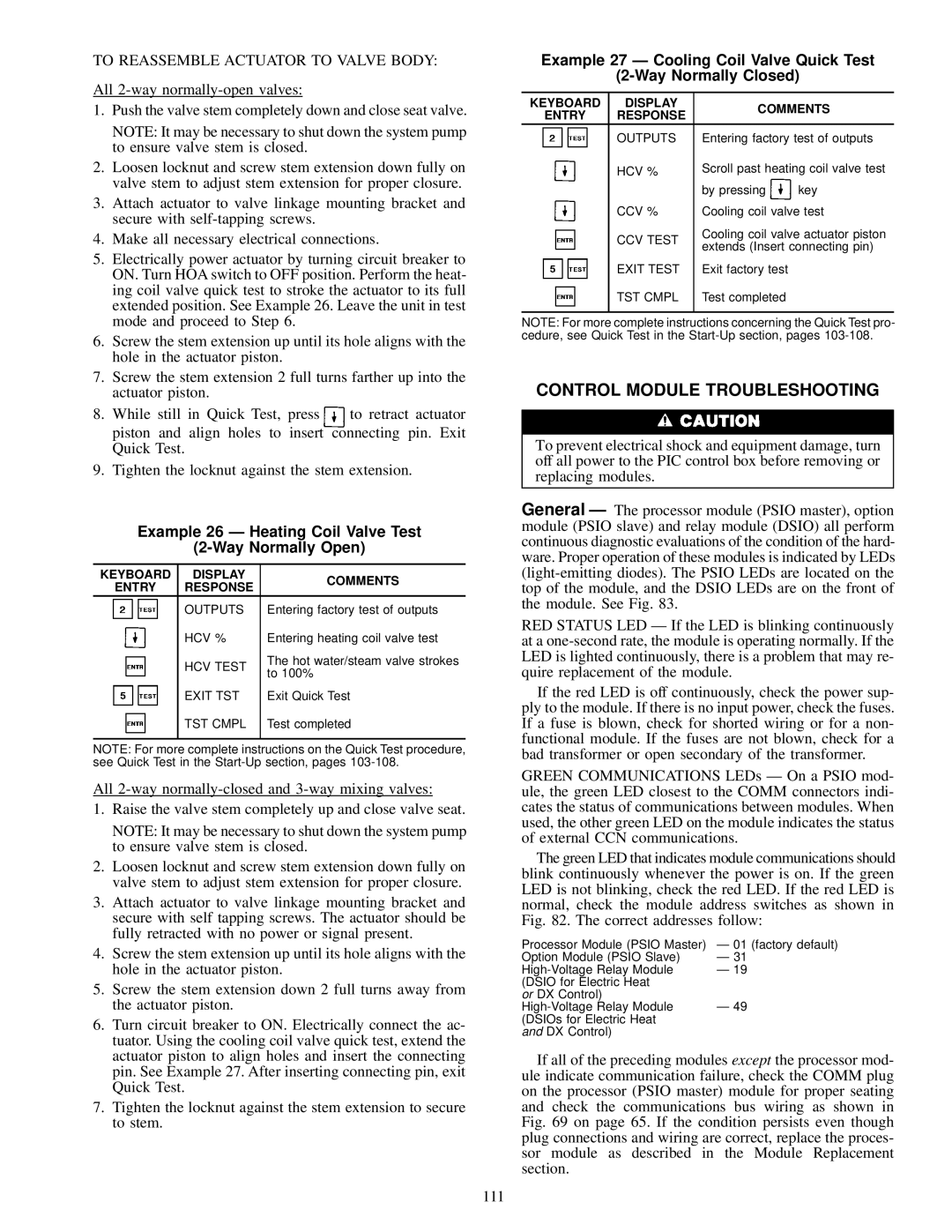

Example 26 Ð Heating Coil Valve Test

(2-Way Normally Open)

| KEYBOARD | DISPLAY | COMMENTS |

| ENTRY | RESPONSE |

| |

| | OUTPUTS | Entering factory test of outputs |

| | HCV % | Entering heating coil valve test |

| | HCV TEST | The hot water/steam valve strokes |

| | to 100% |

| | |

| | EXIT TST | Exit Quick Test |

| | TST CMPL | Test completed |

| | | |

NOTE: For more complete instructions on the Quick Test procedure, see Quick Test in the Start-Up section, pages 103-108.

All 2-way normally-closed and 3-way mixing valves:

1.Raise the valve stem completely up and close valve seat.

NOTE: It may be necessary to shut down the system pump to ensure valve stem is closed.

2.Loosen locknut and screw stem extension down fully on valve stem to adjust stem extension for proper closure.

3.Attach actuator to valve linkage mounting bracket and secure with self tapping screws. The actuator should be fully retracted with no power or signal present.

4.Screw the stem extension up until its hole aligns with the hole in the actuator piston.

5.Screw the stem extension down 2 full turns away from the actuator piston.

6.Turn circuit breaker to ON. Electrically connect the ac- tuator. Using the cooling coil valve quick test, extend the actuator piston to align holes and insert the connecting pin. See Example 27. After inserting connecting pin, exit Quick Test.

7.Tighten the locknut against the stem extension to secure to stem.

Example 27 Ð Cooling Coil Valve Quick Test

(2-Way Normally Closed)

| KEYBOARD | DISPLAY | COMMENTS |

| ENTRY | RESPONSE |

| | |

| | OUTPUTS | Entering factory test of outputs |

| | HCV % | Scroll past heating coil valve test |

| | | by pressing | key |

| | CCV % | Cooling coil valve test |

| | CCV TEST | Cooling coil valve actuator piston |

| | extends (Insert connecting pin) |

| | |

| | EXIT TEST | Exit factory test | |

| | TST CMPL | Test completed | |

| | | | |

NOTE: For more complete instructions concerning the Quick Test pro- cedure, see Quick Test in the Start-Up section, pages 103-108.

CONTROL MODULE TROUBLESHOOTING

To prevent electrical shock and equipment damage, turn off all power to the PIC control box before removing or replacing modules.

General Ð The processor module (PSIO master), option module (PSIO slave) and relay module (DSIO) all perform continuous diagnostic evaluations of the condition of the hard- ware. Proper operation of these modules is indicated by LEDs (light-emitting diodes). The PSIO LEDs are located on the top of the module, and the DSIO LEDs are on the front of the module. See Fig. 83.

RED STATUS LED Ð If the LED is blinking continuously at a one-second rate, the module is operating normally. If the LED is lighted continuously, there is a problem that may re- quire replacement of the module.

If the red LED is off continuously, check the power sup- ply to the module. If there is no input power, check the fuses. If a fuse is blown, check for shorted wiring or for a non- functional module. If the fuses are not blown, check for a bad transformer or open secondary of the transformer.

GREEN COMMUNICATIONS LEDs Ð On a PSIO mod- ule, the green LED closest to the COMM connectors indi- cates the status of communications between modules. When used, the other green LED on the module indicates the status of external CCN communications.

The green LED that indicates module communications should blink continuously whenever the power is on. If the green LED is not blinking, check the red LED. If the red LED is normal, check the module address switches as shown in Fig. 82. The correct addresses follow:

Processor Module (PSIO Master) | Ð 01 (factory default) |

Option Module (PSIO Slave) | Ð 31 |

High-Voltage Relay Module | Ð 19 |

(DSIO for Electric Heat | |

or DX Control) | |

High-Voltage Relay Module | Ð 49 |

(DSIOs for Electric Heat | |

and DX Control) | |

If all of the preceding modules except the processor mod- ule indicate communication failure, check the COMM plug on the processor (PSIO master) module for proper seating and check the communications bus wiring as shown in Fig. 69 on page 65. If the condition persists even though plug connections and wiring are correct, replace the proces- sor module as described in the Module Replacement section.