Installation, Operation, Start-Up Instructions

Contents

Safety Considerations

Installation

General

Page

ABX

IGV

PIC

VAV

Direct Expansion

FMB Ð Filter Mixing Box

MXB Ð Mixing Box

Normally Closed

Control Box for Remote Mounting

AFS

Aotc

AQ1

AQ2

PIC Section Control Box Component Arrangements, 39L

PIC Section Control Box Component Arrangement, 39NX Sizes

PIC Section Control Box Component Arrangement, 39NX Sizes

Page

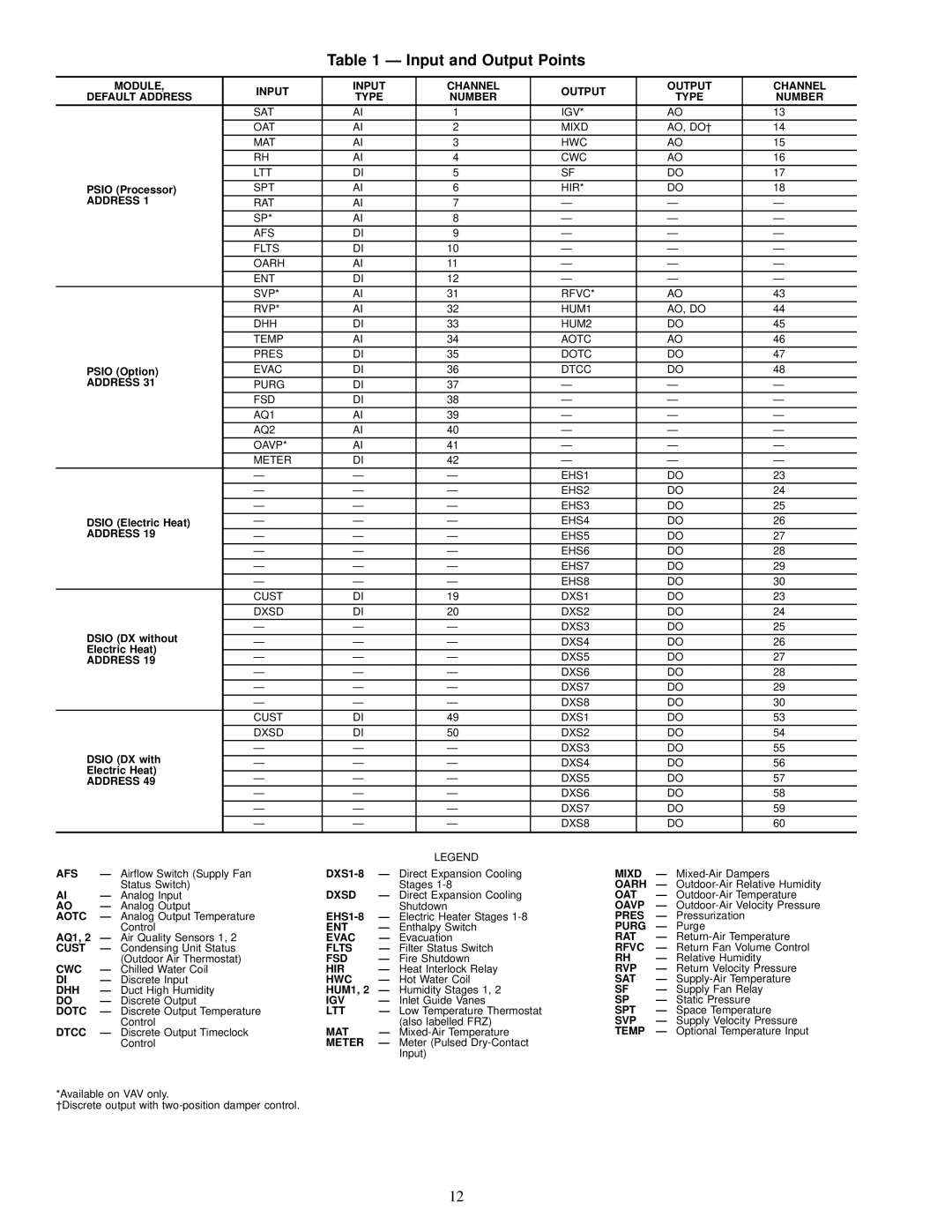

Input and Output Points

Address

Unit Wiring Schematic, 39L Sizes 03-35 115 v, Typical

Unit Wiring Schematic, 39L Sizes 03-35 115 v, Typical

Unit Wiring Schematic, 39L Sizes 03-35 115 v, Typical

Unit Wiring Schematic, 39L Sizes 03-35 115 v, Typical

Unit Wiring Schematic, 39L Sizes 03-35 115 v, Typical

Unit Wiring Schematic, 39L Sizes 03-35 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 07-21 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 07-21 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 07-21 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 07-21 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 07-21 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 07-21 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 26-92 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 26-92 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 26-92 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 26-92 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 26-92 115 v, Typical

Unit Wiring Schematic, 39NX Sizes 26-92 115 v, Typical

Page

Page

Page

Page

Page

Page

Junction Box Connections for Optional Remote Control Box

Terminal Signal

Valve Assembly Typical

Hot Water Valve Wiring

Chilled Water Valve Wiring

Duct Static Pressure Probe

Nema Ð National Electrical Manufacturers Association

Resistance Temperature

Ohms

Mixed-Air Temperature Sensor HH79NZ021 Installation

Enthalpy Control Settings

Supply/Return Air Temperature Sensor HH79NZ019

COI L Comno

Wall-Mounted Relative Humidity Sensor Fig

Duct-Mounted Relative Humidity Sensor Locations

Air¯ow Switch P/N HK06WC030

CO2 Sensor Accessories

CGCDXSEN002A00

CGCDXSEN003A00

CGCDXGAS001A00

Air Quality CO2 Sensor Wall Mount Version Shown

CO2 Concentration PPM

OAC Pressure Transducers

Recommended Sensor Device Wiring

Manufacturer Part Number

Processor

Sensor Module PIN no

Field Wiring of Sensors

Recommended Actuators

Stroke

Field-Supplied Mixing Box Actuator Signal Wiring

HAND/OFF/AUTO Switch Tran Ð Transformer

High-Pressure Switch Remove Jumper

Evacuation Supply Fan Contactor

Fire Shut Down Terminal Block

Pres

Single-Pole, Double-Throw Spdt Relay

Wiring of Device Under Discrete Output Temperature Control

Wiring of Two-Stage Humidication Control Relays

Duct Mounted Relative Humidity Transmitter Wiring

Air Quality and Oavp Sensor Wiring

Wiring of Return Fan Volume Control With IGVs

Pulse-Type Meter Wiring

Control System

CCN Communication Wiring

AHU

Air Handling Unit

Relay Module

Outdoor Air Thermostat

Local Interface Device Key Usage

Function USE Keys

Operative USE Keys

Status History Schedule Service Set Point Test

Functions and Subfunctions

SUB Function Number

Oavp

Control Operation

Operation Keyboard Display Description Entry

Keyboard Directory

Status

Inputs

VAV

Direct Expansion Oavp Ð Outside Air Velocity Pressure

AIRQUAL1

SET Point

Quick Test

History

Example 1 Ð Reading Alarm Codes

Example 2 Ð Reading Current Operating Modes

Keyboard Display Comments Entry Response

Alarms

Display Codes

Force States

Display Description

State of Items Controlled

Example 3 Ð Forcing An Input Value

Example 4 Ð Forcing An Output Value

Relay Stages

Example 5 Ð Using Quick Test

Example 6 Ð Logging On and Logging Off Service Function

Keyboard Display Comments Entry Response To LOG on

To LOG OFF

Service Conguration Ranges and Defaults

Analog Output Temperature Control

Example 7 Ð Reading and Changing Factory Congurations

Example 8 Ð Conguration of Measurements

Example 9 Ð User Congurations

Example 11 Ð Conguration of Space Temperature Reset

Example 10 Ð Conguration of Heating Coil

Example 12 Ð Conguration of Loadshed

Example 14 Ð Conguration of Alarm Limits

Example 15 Ð Conguration of Analog Temperature Control

Example 13 Ð Conguration of Fan Tracking

Example 16 Ð Conguration of Discrete Temperature Control

Example 17 Ð Service History Conguration

Example 18 Ð Service/Maintenance Alarm Conguration

Set Point Ranges and Defaults

Example 21 Ð Setting of Time and Date

Example 22 Ð Setting Daylight Savings Time

Example 20 Ð Reading and Changing System Set Points

Example 23 Ð Setting of Holidays

Schedule I Sample Time Schedule

Example 24 Ð Using the Schedule Function

Keyboard Display Comment Entry Response Programming Period

Period 1 Dene schedule period

For this example, Period 6 is used for holiday only

Constant Volume and Variable Air Volume Units

Control Operating Sequence

Page

Page

MAT Ð Mixed-Air Temperature

OAT Ð Outdoor-Air Temperature

IAQ

Indoor-Air Quality

Constant Volume Units Only

CCV Ð Cooling Coil Valve

RAT Ð Return-Air

DX Submaster Gain Control Operation

Variable Air Volume Units Only

Page

Outside Air

OAC

Constant Outside Air

Oavp Ð Outside Air Velocity Pressure

102

START-UP

Initial Check

Test of Input Signals

Keyboard Display COMMENTS/ACTION Entry Response

Keyboard Display COMMENTS/ACTION Entry Response FSD NRM

Following

Test of Output Signals

For Variable Air Volume Units

Test of Output Options Using Option Module

Electric Heater Test

Control Loop Checkout

Direct Expansion DX Cooling Test

Digital DC Volt Meter vs DC Milliamp Meter

DC Milliamps DC Voltage

Valve Troubleshooting

Recommended Gain Starting Valves

Typical Linkages

Example 25 Ð Forcing An Output

IGV %

HCV 10/FORCED

Control Module Troubleshooting

Example 26 Ð Heating Coil Valve Test Way Normally Open

Exit Test

Dsio

Unit Troubleshooting

Problem Possible Cause Corrective Action

HCV, CCV, IGV

IAQ features

OAC malfunctioning

Malfunctioning

Metric Conversion Chart