Centering Fan Wheel Ð If fan and fan shaft assem- bly are not properly centered, blades may scrape against scroll or may create an objectionable whistling noise. It may be necessary to adjust individual fan wheels or move entire fan shaft. See the following two sections.

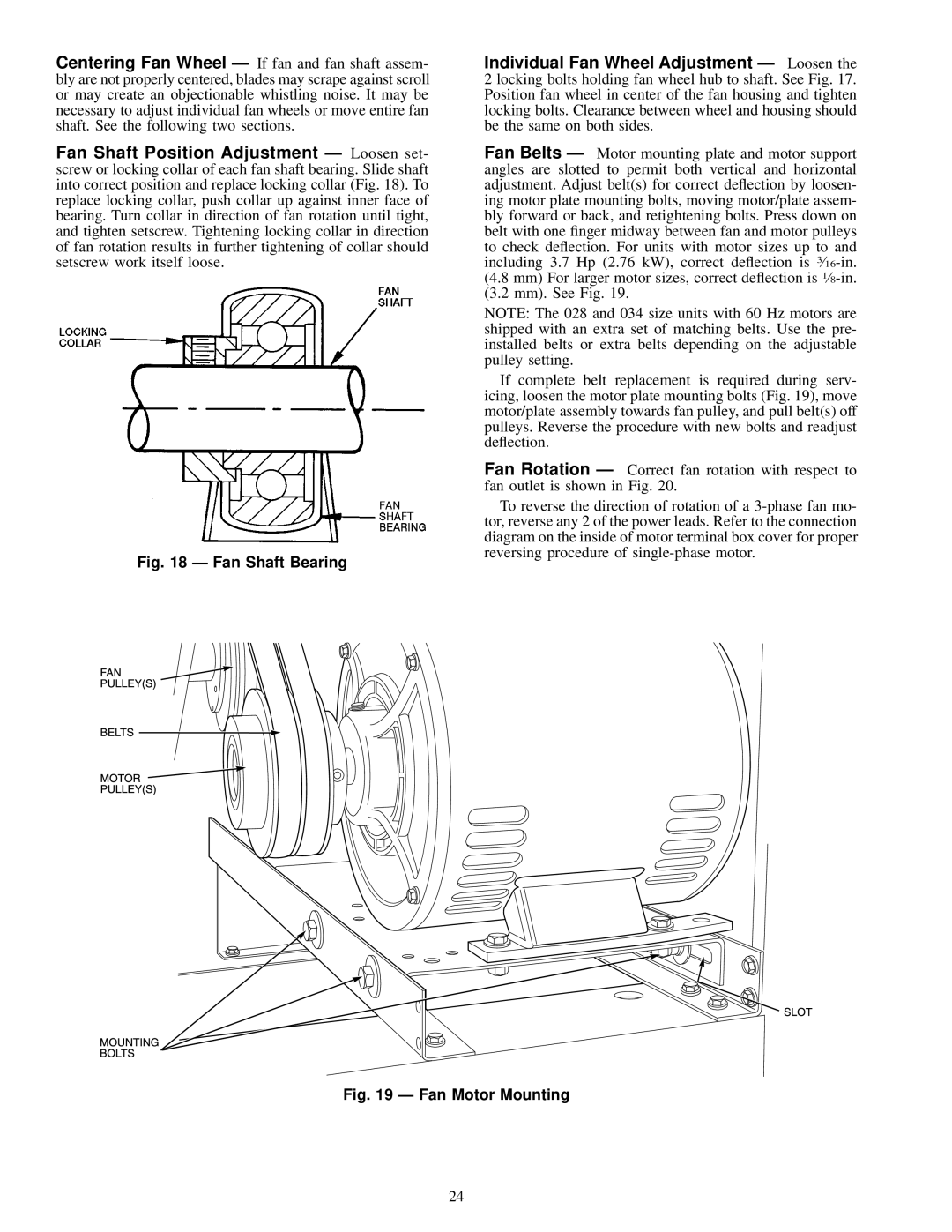

Fan Shaft Position Adjustment Ð Loosen set- screw or locking collar of each fan shaft bearing. Slide shaft into correct position and replace locking collar (Fig. 18). To replace locking collar, push collar up against inner face of bearing. Turn collar in direction of fan rotation until tight, and tighten setscrew. Tightening locking collar in direction of fan rotation results in further tightening of collar should setscrew work itself loose.

Fig. 18 Ð Fan Shaft Bearing

Individual Fan Wheel Adjustment Ð Loosen the 2 locking bolts holding fan wheel hub to shaft. See Fig. 17. Position fan wheel in center of the fan housing and tighten locking bolts. Clearance between wheel and housing should be the same on both sides.

Fan Belts Ð Motor mounting plate and motor support angles are slotted to permit both vertical and horizontal adjustment. Adjust belt(s) for correct de¯ection by loosen- ing motor plate mounting bolts, moving motor/plate assem- bly forward or back, and retightening bolts. Press down on belt with one ®nger midway between fan and motor pulleys to check de¯ection. For units with motor sizes up to and including 3.7 Hp (2.76 kW), correct de¯ection is

NOTE: The 028 and 034 size units with 60 Hz motors are shipped with an extra set of matching belts. Use the pre- installed belts or extra belts depending on the adjustable pulley setting.

If complete belt replacement is required during serv- icing, loosen the motor plate mounting bolts (Fig. 19), move motor/plate assembly towards fan pulley, and pull belt(s) off pulleys. Reverse the procedure with new bolts and readjust de¯ection.

Fan Rotation Ð Correct fan rotation with respect to fan outlet is shown in Fig. 20.

To reverse the direction of rotation of a

Fig. 19 Ð Fan Motor Mounting

24