START-UP

Unit Preparation — Make sure that unit has been in- stalled in accordance with these installation instructions and applicable codes.

Return-Air Filters — Make sure correct filters are in- stalled in filter tracks. See Table 1. Do not operate unit without return-air filters.

Compressor Mounting — Compressors are internally spring mounted. Do not loosen or remove compressor hold- down bolts.

Internal Wiring — Check all electrical connections in unit control boxes. Tighten as required.

Refrigerant Service Ports — To service refrigerant service ports, remove compressor access panel. Each unit sys- tem has 4 Schrader-type service gage ports: one on the suction line, one on the liquid line, and two on the compressor dis- charge line. Be sure that caps on the ports are tight. One Schrader-type valve is located under both the high-pressure switch and the low-pressure switch.

High Flow Valves — Located on the compressor hot gas and suction tubes are High Flow Valves. Large black plastic caps distinguish these valves with o-rings located inside the caps. These valves cannot be accessed for service in the field. Ensure the plastic caps are in place and tight or the possibility of refrigerant leakage could occur.

Compressor Rotation — On 3-phase units with scroll compressors, it is important to be certain compressor is rotating in the proper direction. To determine whether or not compres- sor is rotating in the proper direction:

1.Connect service gages to suction and discharge pressure fittings.

2.Energize the compressor.

3.The suction pressure should drop and the discharge pres- sure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pres- sure does not rise to normal levels:

1.Note that the evaporator fan is probably also rotating in the wrong direction.

2.Turn off power to the unit.

3.Reverse any two of the unit power leads.

4.Reapply power to the compressor.

The suction and discharge pressure levels should now move to their normal start-up levels.

NOTE: When the compressor is rotating in the wrong direc- tion, the unit makes an elevated level of noise and does not provide cooling.

Cooling — Set space thermostat to OFF position. To start unit, turn on main power supply. Set system selector switch at COOL position and fan switch at AUTO. position. Adjust ther- mostat to a setting below room temperature. Compressor starts on closure of contactor.

Check unit charge. Refer to Service, Refrigerant Charge section, page 39.

Reset thermostat at a position above room temperature. Compressor will shut off. Evaporator fan will shut off after 30-second delay.

TO SHUT OFF UNIT — Set system selector switch at OFF position. Resetting thermostat at a position above room tem- perature shuts unit off temporarily until space temperature ex- ceeds thermostat setting.

Main Burners — Main burners are factory set and should require no adjustment.

TO CHECK ignition of main burners and heating controls, move thermostat set point above room temperature and verify that the burners light and evaporator fan is energized. After ensuring that the unit continues to heat the building, lower the thermostat setting below room temperature and verify that the burners and evaporator fan turn off. (Fan will turn off only if fan selector switch is in the AUTO. position.)

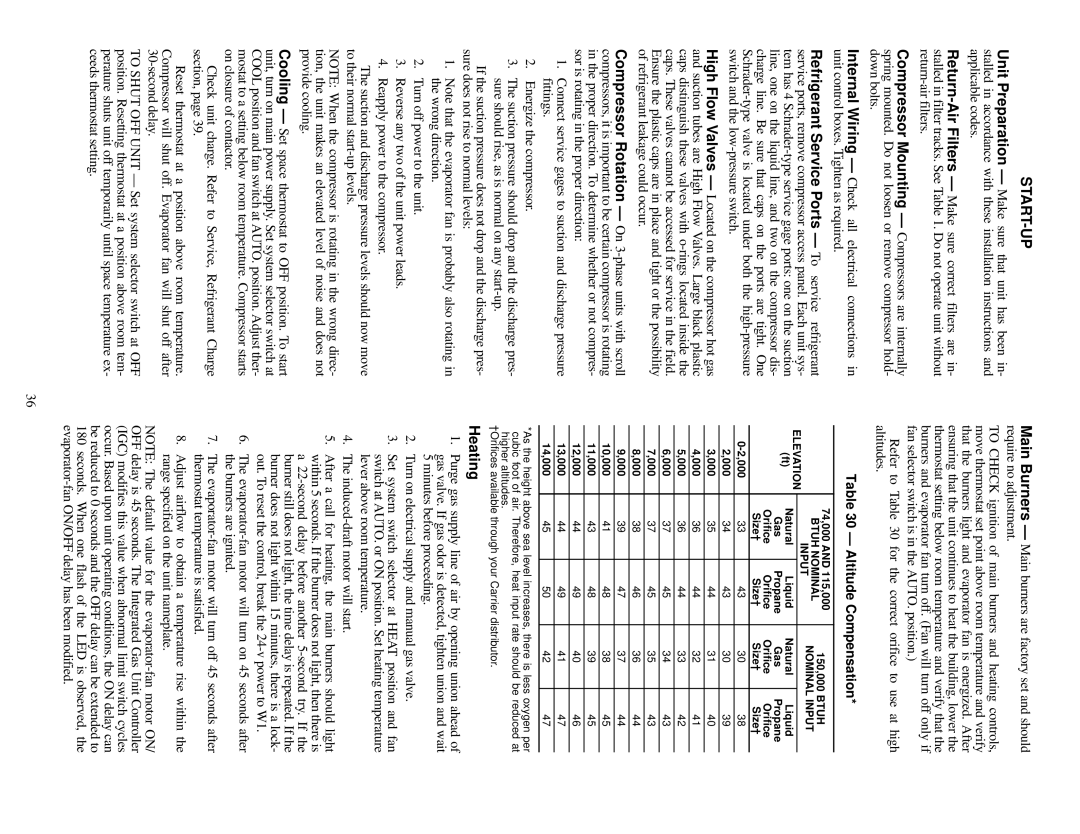

Refer to Table 30 for the correct orifice to use at high altitudes.

Table 30 — Altitude Compensation*

| | 74,000 AND 115,000 | 150,000 BTUH |

| | BTUH NOMINAL |

| | NOMINAL INPUT |

| | INPUT |

| ELEVATION | | |

| (ft) | Natural | Liquid | Natural | Liquid |

| Gas | Propane | Gas | Propane |

| |

| | Orifice | Orifice | Orifice | Orifice |

| | Size† | Size† | Size† | Size† |

| 0-2,000 | 33 | 43 | 30 | 38 |

| 2,000 | 34 | 43 | 30 | 39 |

| 3,000 | 35 | 44 | 31 | 40 |

| 4,000 | 36 | 44 | 32 | 41 |

| 5,000 | 36 | 44 | 33 | 42 |

| 6,000 | 37 | 45 | 34 | 43 |

| 7,000 | 37 | 45 | 35 | 43 |

| 8,000 | 38 | 46 | 36 | 44 |

| 9,000 | 39 | 47 | 37 | 44 |

| 10,000 | 41 | 48 | 38 | 45 |

| 11,000 | 43 | 48 | 39 | 45 |

| 12,000 | 44 | 49 | 40 | 46 |

| 13,000 | 44 | 49 | 41 | 47 |

| 14,000 | 45 | 50 | 42 | 47 |

*As the height above sea level increases, there is less oxygen per cubic foot of air. Therefore, heat input rate should be reduced at higher altitudes.

†Orifices available through your Carrier distributor.

Heating

1.Purge gas supply line of air by opening union ahead of gas valve. If gas odor is detected, tighten union and wait 5 minutes before proceeding.

2.Turn on electrical supply and manual gas valve.

3.Set system switch selector at HEAT position and fan switch at AUTO. or ON position. Set heating temperature lever above room temperature.

4.The induced-draft motor will start.

5.After a call for heating, the main burners should light within 5 seconds. If the burner does not light, then there is a 22-second delay before another 5-second try. If the burner still does not light, the time delay is repeated. If the burner does not light within 15 minutes, there is a lock- out. To reset the control, break the 24-v power to W1.

6.The evaporator-fan motor will turn on 45 seconds after the burners are ignited.

7.The evaporator-fan motor will turn off 45 seconds after thermostat temperature is satisfied.

8.Adjust airflow to obtain a temperature rise within the range specified on the unit nameplate.

NOTE: The default value for the evaporator-fan motor ON/ OFF delay is 45 seconds. The Integrated Gas Unit Controller (IGC) modifies this value when abnormal limit switch cycles occur. Based upon unit operating conditions, the ON delay can be reduced to 0 seconds and the OFF delay can be extended to 180 seconds. When one flash of the LED is observed, the evaporator-fan ON/OFF delay has been modified.