INSTALL FLANGES FOR DUCTWORK CONNECTIONS (50ZH060 ONLY)

The 50ZH060 units are shipped with flanges which must be

To install unit flanges:

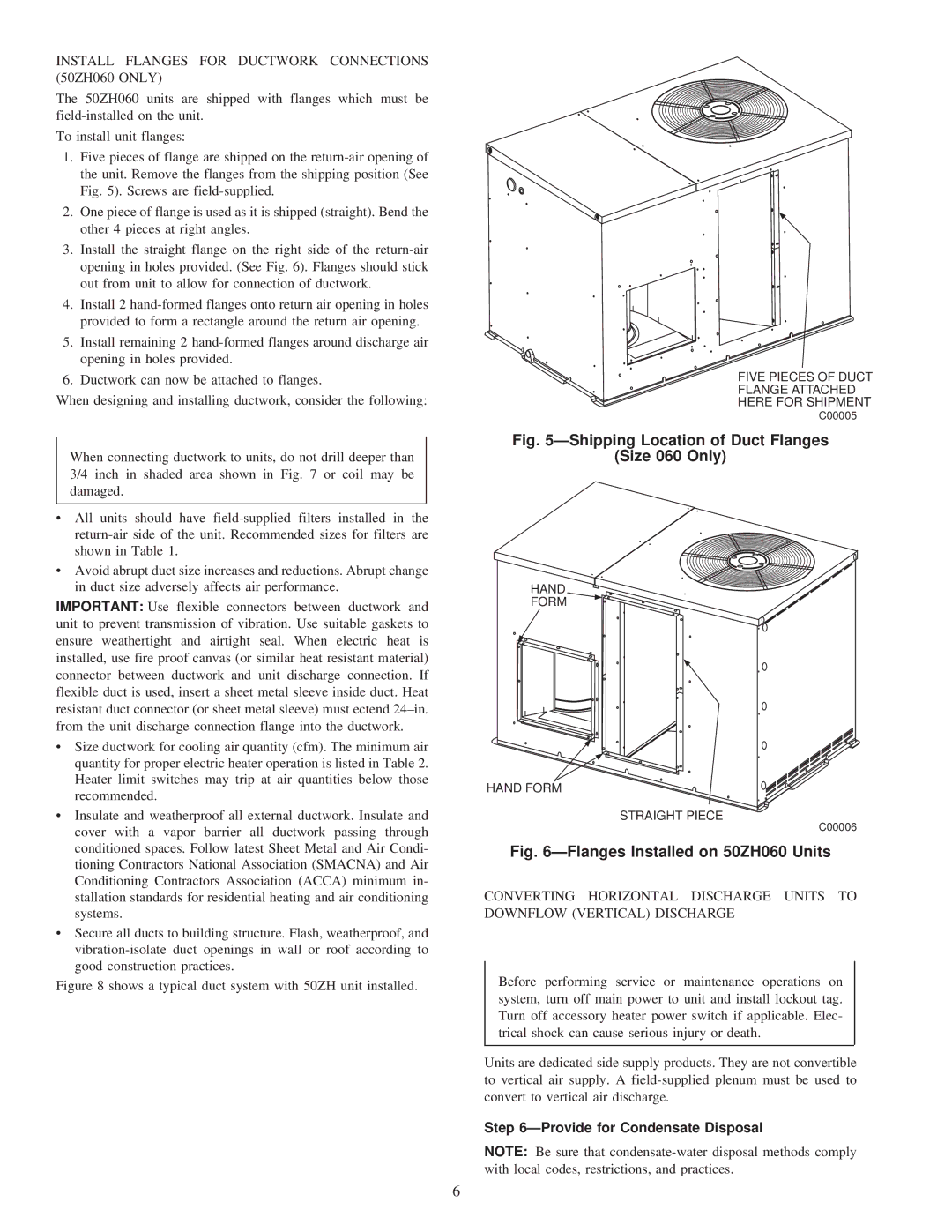

1.Five pieces of flange are shipped on the

2.One piece of flange is used as it is shipped (straight). Bend the other 4 pieces at right angles.

3.Install the straight flange on the right side of the

4.Install 2

5.Install remaining 2

6.Ductwork can now be attached to flanges.

When designing and installing ductwork, consider the following:

When connecting ductwork to units, do not drill deeper than 3/4 inch in shaded area shown in Fig. 7 or coil may be damaged.

·All units should have

·Avoid abrupt duct size increases and reductions. Abrupt change in duct size adversely affects air performance.

IMPORTANT: Use flexible connectors between ductwork and unit to prevent transmission of vibration. Use suitable gaskets to ensure weathertight and airtight seal. When electric heat is installed, use fire proof canvas (or similar heat resistant material) connector between ductwork and unit discharge connection. If flexible duct is used, insert a sheet metal sleeve inside duct. Heat resistant duct connector (or sheet metal sleeve) must ectend 24±in. from the unit discharge connection flange into the ductwork.

·Size ductwork for cooling air quantity (cfm). The minimum air quantity for proper electric heater operation is listed in Table 2. Heater limit switches may trip at air quantities below those recommended.

·Insulate and weatherproof all external ductwork. Insulate and cover with a vapor barrier all ductwork passing through conditioned spaces. Follow latest Sheet Metal and Air Condi- tioning Contractors National Association (SMACNA) and Air Conditioning Contractors Association (ACCA) minimum in- stallation standards for residential heating and air conditioning systems.

·Secure all ducts to building structure. Flash, weatherproof, and

Figure 8 shows a typical duct system with 50ZH unit installed.

FIVE PIECES OF DUCT

FLANGE ATTACHED

HERE FOR SHIPMENT

C00005

Fig. 5ÐShipping Location of Duct Flanges

(Size 060 Only)

HAND

FORM

HAND FORM

STRAIGHT PIECE

C00006

Fig. 6ÐFlanges Installed on 50ZH060 Units

CONVERTING HORIZONTAL DISCHARGE UNITS TO DOWNFLOW (VERTICAL) DISCHARGE

Before performing service or maintenance operations on system, turn off main power to unit and install lockout tag. Turn off accessory heater power switch if applicable. Elec- trical shock can cause serious injury or death.

Units are dedicated side supply products. They are not convertible to vertical air supply. A

Step 6ÐProvide for Condensate Disposal

NOTE: Be sure that

6