PER NEC

UNIT GROUND

GROUND

LEAD

LBLK

L | YEL |

L | BLU |

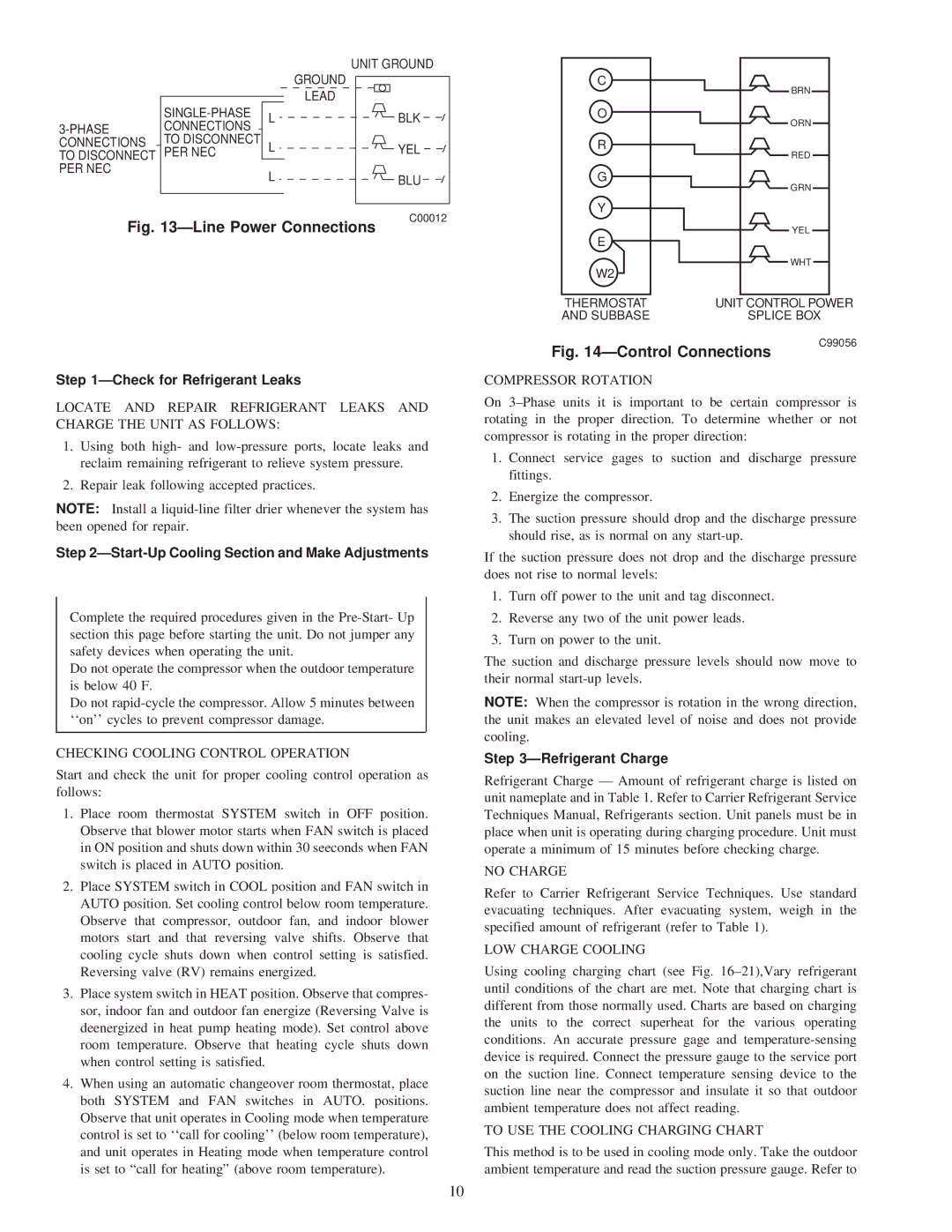

C

BRN

O

ORN

R

RED

G

GRN |

Y |

Fig. 13ÐLine Power Connections

Step 1ÐCheck for Refrigerant Leaks

C00012

E | YEL |

| |

W2 | WHT |

| |

THERMOSTAT | UNIT CONTROL POWER |

AND SUBBASE | SPLICE BOX |

| C99056 |

Fig. 14ÐControl Connections

COMPRESSOR ROTATION

LOCATE AND REPAIR REFRIGERANT LEAKS AND CHARGE THE UNIT AS FOLLOWS:

1.Using both high- and

2.Repair leak following accepted practices.

NOTE: Install a

Step 2ÐStart-Up Cooling Section and Make Adjustments

Complete the required procedures given in the

Do not operate the compressor when the outdoor temperature is below 40 F.

Do not

CHECKING COOLING CONTROL OPERATION

Start and check the unit for proper cooling control operation as follows:

1.Place room thermostat SYSTEM switch in OFF position. Observe that blower motor starts when FAN switch is placed in ON position and shuts down within 30 seeconds when FAN switch is placed in AUTO position.

2.Place SYSTEM switch in COOL position and FAN switch in AUTO position. Set cooling control below room temperature. Observe that compressor, outdoor fan, and indoor blower motors start and that reversing valve shifts. Observe that cooling cycle shuts down when control setting is satisfied. Reversing valve (RV) remains energized.

3.Place system switch in HEAT position. Observe that compres- sor, indoor fan and outdoor fan energize (Reversing Valve is deenergized in heat pump heating mode). Set control above room temperature. Observe that heating cycle shuts down when control setting is satisfied.

4.When using an automatic changeover room thermostat, place both SYSTEM and FAN switches in AUTO. positions. Observe that unit operates in Cooling mode when temperature control is set to ``call for cooling'' (below room temperature), and unit operates in Heating mode when temperature control is set to ªcall for heatingº (above room temperature).

On 3±Phase units it is important to be certain compressor is rotating in the proper direction. To determine whether or not compressor is rotating in the proper direction:

1.Connect service gages to suction and discharge pressure fittings.

2.Energize the compressor.

3.The suction pressure should drop and the discharge pressure should rise, as is normal on any

If the suction pressure does not drop and the discharge pressure does not rise to normal levels:

1.Turn off power to the unit and tag disconnect.

2.Reverse any two of the unit power leads.

3.Turn on power to the unit.

The suction and discharge pressure levels should now move to their normal

NOTE: When the compressor is rotation in the wrong direction, the unit makes an elevated level of noise and does not provide cooling.

Step 3ÐRefrigerant Charge

Refrigerant Charge Ð Amount of refrigerant charge is listed on unit nameplate and in Table 1. Refer to Carrier Refrigerant Service Techniques Manual, Refrigerants section. Unit panels must be in place when unit is operating during charging procedure. Unit must operate a minimum of 15 minutes before checking charge.

NO CHARGE

Refer to Carrier Refrigerant Service Techniques. Use standard evacuating techniques. After evacuating system, weigh in the specified amount of refrigerant (refer to Table 1).

LOW CHARGE COOLING

Using cooling charging chart (see Fig. 16±21),Vary refrigerant until conditions of the chart are met. Note that charging chart is different from those normally used. Charts are based on charging the units to the correct superheat for the various operating conditions. An accurate pressure gage and

TO USE THE COOLING CHARGING CHART

This method is to be used in cooling mode only. Take the outdoor ambient temperature and read the suction pressure gauge. Refer to

10