Table 3 – Minimum Space volumes for 100% combustion, Ventilation, and Dilution from Indoors

| OTHER THAN |

|

|

|

|

| ||||||

ACH* |

| (1,000’S BTUH GAS INPUT RATE |

|

|

| (1,000’S BTUH GAS INPUT RATE) |

| |||||

|

|

|

|

|

|

|

|

|

|

|

| |

30 |

| 40 | 50 |

| 44 |

| 66 |

| 88 | 110 | 132 | |

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Space | Volume (ft.3) |

|

|

|

|

| |

0.60 | 1,050 | 1,400 | 1,750 | 1,100 |

| 1,650 | 2,200 | 2,750 | 3,300 | |||

|

|

|

|

|

|

|

|

|

| |||

0.50 | 1,260 | 1,680 | 2,100 | 1,320 |

| 1,980 | 2,640 | 3,300 | 3,960 | |||

|

|

|

|

|

|

|

|

|

| |||

0.40 | 1,575 | 2,100 | 2,625 | 1,650 |

| 2,475 | 3,300 | 4,125 | 4,950 | |||

|

|

|

|

|

|

|

|

|

| |||

0.30 | 2,100 | 2,800 | 3,500 | 2,200 |

| 3,300 | 4,400 | 5,500 | 6,600 | |||

|

|

|

|

|

|

|

|

|

| |||

0.20 | 3,150 | 4,200 | 5,250 | 3,300 |

| 4,950 | 6,600 | 8,250 | 9,900 | |||

|

|

|

|

|

|

|

|

|

| |||

0.10 | 6,300 | 8,400 | 10,500 | 6,600 |

| 9,900 | 13,200 | 16,500 | 19,800 | |||

|

|

|

|

|

|

|

|

|

|

|

| |

0.00 | NP |

| NP | NP |

| NP | NP |

| NP | NP | NP | |

*Air Changes/Hour

58PHA

!WARNING

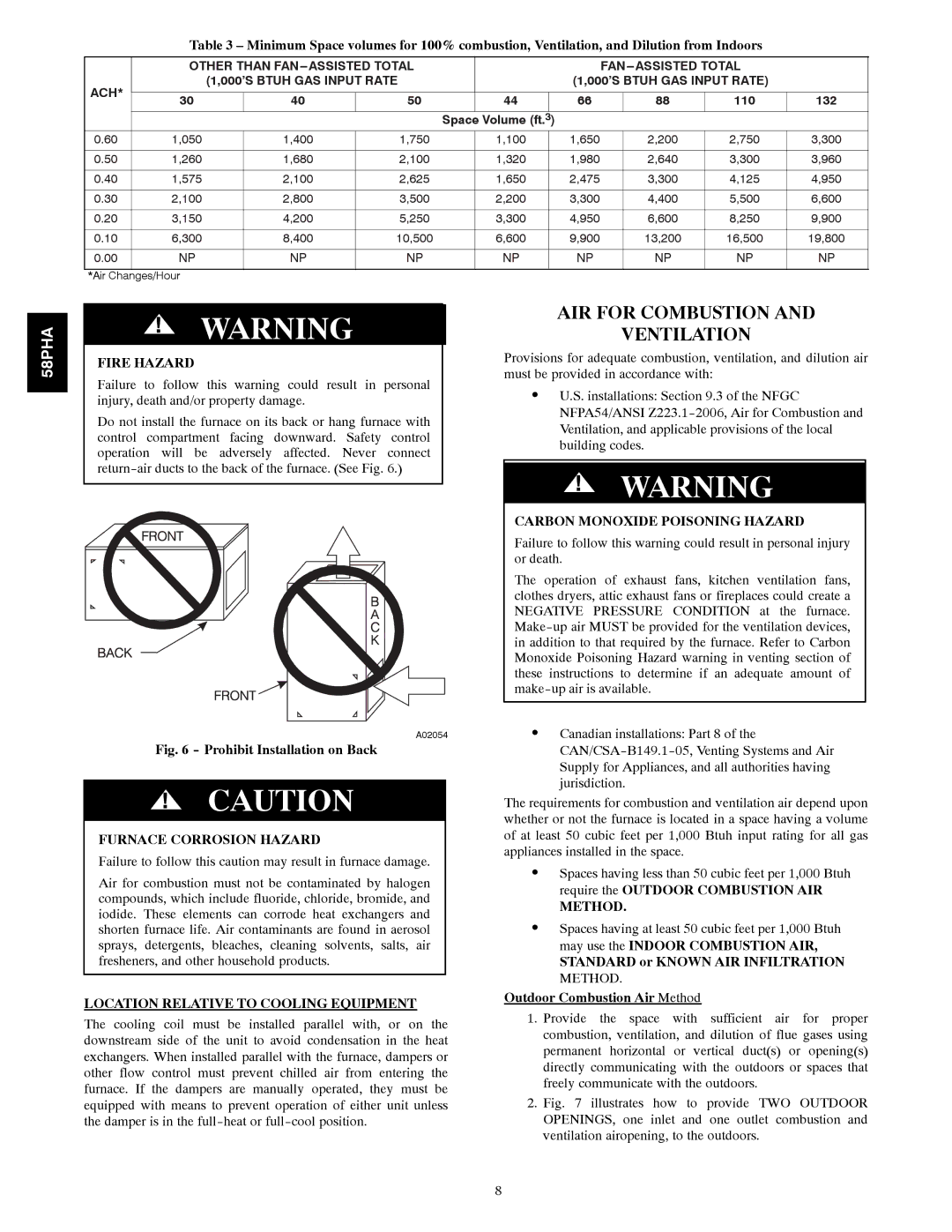

FIRE HAZARD

Failure to follow this warning could result in personal injury, death and/or property damage.

Do not install the furnace on its back or hang furnace with control compartment facing downward. Safety control operation will be adversely affected. Never connect

A02054

Fig. 6 - Prohibit Installation on Back

!CAUTION

FURNACE CORROSION HAZARD

Failure to follow this caution may result in furnace damage.

Air for combustion must not be contaminated by halogen compounds, which include fluoride, chloride, bromide, and iodide. These elements can corrode heat exchangers and shorten furnace life. Air contaminants are found in aerosol sprays, detergents, bleaches, cleaning solvents, salts, air fresheners, and other household products.

LOCATION RELATIVE TO COOLING EQUIPMENT

The cooling coil must be installed parallel with, or on the downstream side of the unit to avoid condensation in the heat exchangers. When installed parallel with the furnace, dampers or other flow control must prevent chilled air from entering the furnace. If the dampers are manually operated, they must be equipped with means to prevent operation of either unit unless the damper is in the

AIR FOR COMBUSTION AND

VENTILATION

Provisions for adequate combustion, ventilation, and dilution air must be provided in accordance with:

SU.S. installations: Section 9.3 of the NFGC NFPA54/ANSI

!WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or death.

The operation of exhaust fans, kitchen ventilation fans, clothes dryers, attic exhaust fans or fireplaces could create a NEGATIVE PRESSURE CONDITION at the furnace.

SCanadian installations: Part 8 of the

The requirements for combustion and ventilation air depend upon whether or not the furnace is located in a space having a volume of at least 50 cubic feet per 1,000 Btuh input rating for all gas appliances installed in the space.

SSpaces having less than 50 cubic feet per 1,000 Btuh require the OUTDOOR COMBUSTION AIR

METHOD.

SSpaces having at least 50 cubic feet per 1,000 Btuh may use the INDOOR COMBUSTION AIR,

STANDARD or KNOWN AIR INFILTRATION METHOD.

Outdoor Combustion Air Method

1.Provide the space with sufficient air for proper combustion, ventilation, and dilution of flue gases using permanent horizontal or vertical duct(s) or opening(s) directly communicating with the outdoors or spaces that freely communicate with the outdoors.

2.Fig. 7 illustrates how to provide TWO OUTDOOR OPENINGS, one inlet and one outlet combustion and ventilation airopening, to the outdoors.

8