5/16″

(8mm)

(8mm)

5/16″

1 3/4″ (44mm)

1 3/4″ (44mm)

(8mm)

5/16″

(8mm)

5/16″

(44mm) 1 3/4″ (44mm)1 3/4″

A89014

Fig. 10 - Leveling Legs

4.Adjust outside nut to provide desired height, and tighten inside nut to secure arrangement.

5.Reinstall bottom closure panel if removed.

DOWNFLOW INSTALLATION

NOTE: For downflow applications, this furnace is approved for use on combustible flooring when any one of the following 3 accessories are used:

SSpecial Base, KGASB

SCased Coil Assembly Part No. CNPV, CNRV, CAP, or

CAR

SCoil Box Part No. KCAKC

1.Determine application being installed from Table 4.

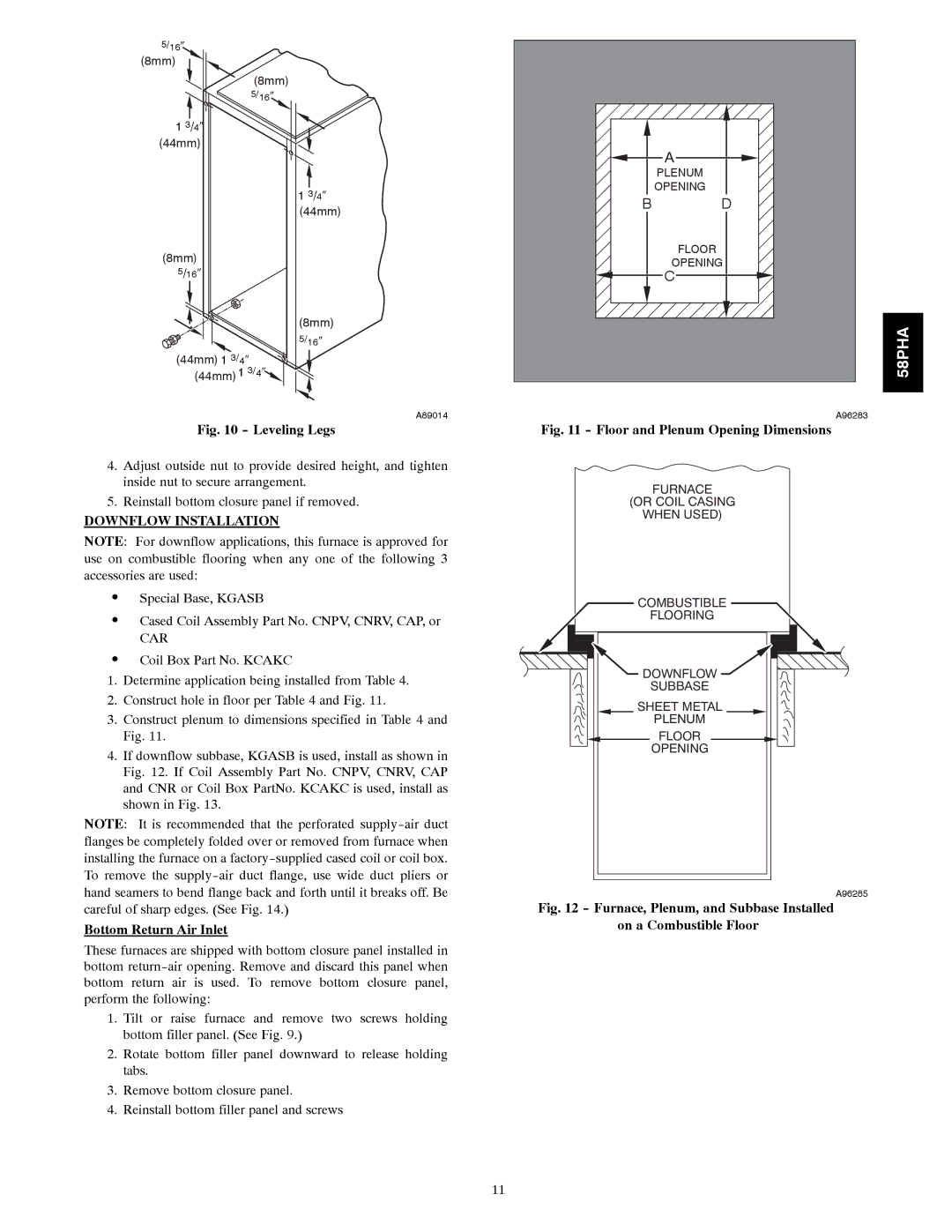

2.Construct hole in floor per Table 4 and Fig. 11.

3.Construct plenum to dimensions specified in Table 4 and Fig. 11.

4.If downflow subbase, KGASB is used, install as shown in Fig. 12. If Coil Assembly Part No. CNPV, CNRV, CAP and CNR or Coil Box PartNo. KCAKC is used, install as shown in Fig. 13.

NOTE: It is recommended that the perforated

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

1.Tilt or raise furnace and remove two screws holding bottom filler panel. (See Fig. 9.)

2.Rotate bottom filler panel downward to release holding tabs.

3.Remove bottom closure panel.

4.Reinstall bottom filler panel and screws

| A |

| PLENUM |

| OPENING |

B | D |

| FLOOR |

| OPENING |

| C |

58PHA

A96283

Fig. 11 - Floor and Plenum Opening Dimensions

FURNACE

(OR COIL CASING

WHEN USED)

COMBUSTIBLE

FLOORING

DOWNFLOW |

SUBBASE |

SHEET METAL |

PLENUM |

FLOOR |

OPENING |

A96285

Fig. 12 - Furnace, Plenum, and Subbase Installed on a Combustible Floor

11