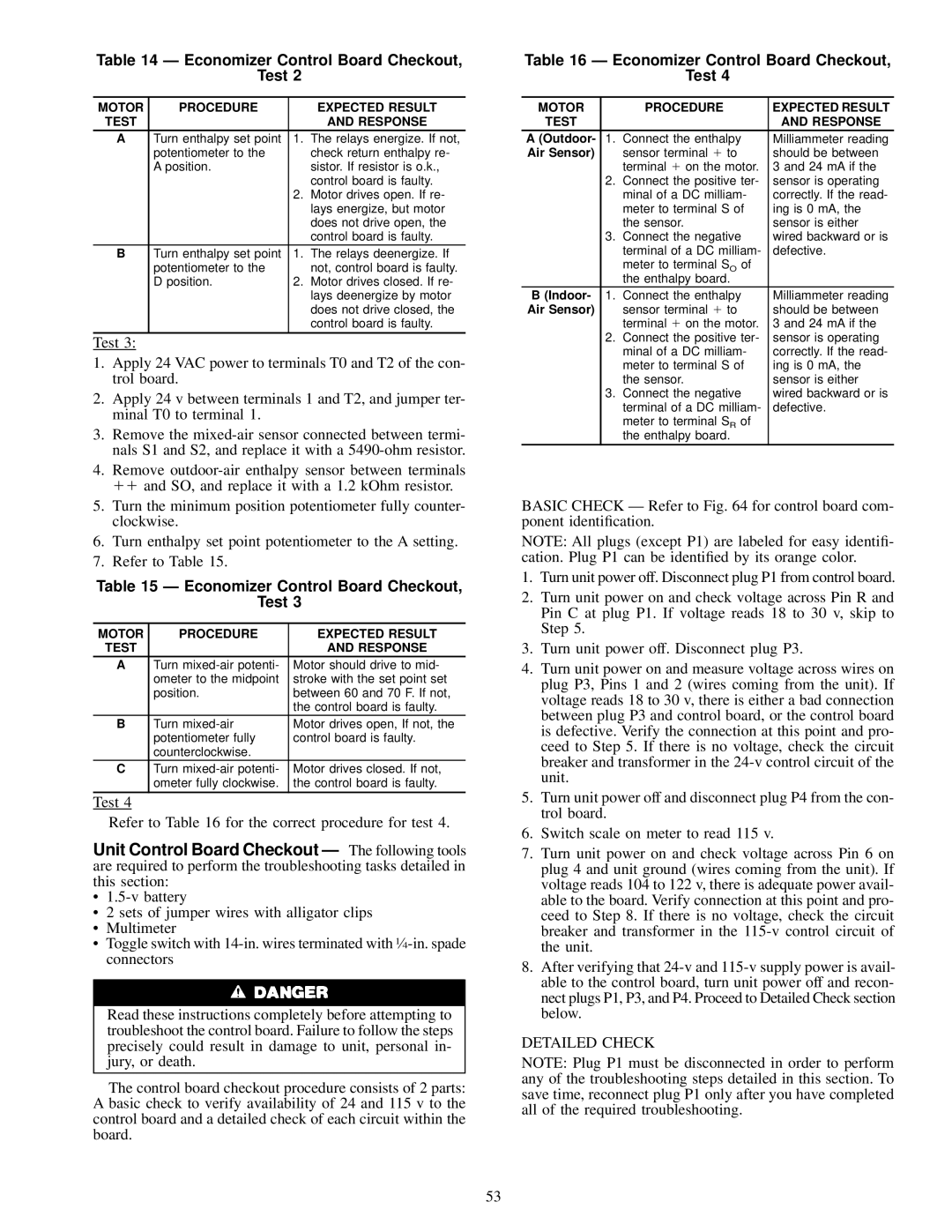

Table 14 Ð Economizer Control Board Checkout,

Test 2

MOTOR | PROCEDURE | | EXPECTED RESULT |

TEST | | | AND RESPONSE |

A | Turn enthalpy set point | 1. | The relays energize. If not, |

| potentiometer to the | | check return enthalpy re- |

| A position. | | sistor. If resistor is o.k., |

| | | control board is faulty. |

| | 2. | Motor drives open. If re- |

| | | lays energize, but motor |

| | | does not drive open, the |

| | | control board is faulty. |

B | Turn enthalpy set point | 1. | The relays deenergize. If |

| potentiometer to the | | not, control board is faulty. |

| D position. | 2. | Motor drives closed. If re- |

| | | lays deenergize by motor |

| | | does not drive closed, the |

| | | control board is faulty. |

| | | |

Test 3:

1.Apply 24 VAC power to terminals T0 and T2 of the con- trol board.

2.Apply 24 v between terminals 1 and T2, and jumper ter- minal T0 to terminal 1.

3.Remove the mixed-air sensor connected between termi- nals S1 and S2, and replace it with a 5490-ohm resistor.

4.Remove outdoor-air enthalpy sensor between terminals 11 and SO, and replace it with a 1.2 kOhm resistor.

5.Turn the minimum position potentiometer fully counter- clockwise.

6.Turn enthalpy set point potentiometer to the A setting.

7.Refer to Table 15.

Table 15 Ð Economizer Control Board Checkout,

Test 3

MOTOR | PROCEDURE | EXPECTED RESULT |

TEST | | AND RESPONSE |

A | Turn mixed-air potenti- | Motor should drive to mid- |

| ometer to the midpoint | stroke with the set point set |

| position. | between 60 and 70 F. If not, |

| | the control board is faulty. |

B | Turn mixed-air | Motor drives open, If not, the |

| potentiometer fully | control board is faulty. |

| counterclockwise. | |

C | Turn mixed-air potenti- | Motor drives closed. If not, |

| ometer fully clockwise. | the control board is faulty. |

| | |

Test 4

Refer to Table 16 for the correct procedure for test 4.

Unit Control Board Checkout Ð The following tools are required to perform the troubleshooting tasks detailed in this section:

·1.5-v battery

·2 sets of jumper wires with alligator clips

·Multimeter

·Toggle switch with 14-in. wires terminated with 1¤4-in. spade connectors

Read these instructions completely before attempting to troubleshoot the control board. Failure to follow the steps precisely could result in damage to unit, personal in- jury, or death.

The control board checkout procedure consists of 2 parts: A basic check to verify availability of 24 and 115 v to the control board and a detailed check of each circuit within the board.

Table 16 Ð Economizer Control Board Checkout,

Test 4

MOTOR | | PROCEDURE | EXPECTED RESULT |

TEST | | | AND RESPONSE |

A (Outdoor- | 1. | Connect the enthalpy | Milliammeter reading |

Air Sensor) | | sensor terminal 1 to | should be between |

| | terminal 1 on the motor. | 3 and 24 mA if the |

| 2. | Connect the positive ter- | sensor is operating |

| | minal of a DC milliam- | correctly. If the read- |

| | meter to terminal S of | ing is 0 mA, the |

| | the sensor. | sensor is either |

| 3. | Connect the negative | wired backward or is |

| | terminal of a DC milliam- | defective. |

| | meter to terminal SO of | |

| | the enthalpy board. | |

B (Indoor- | 1. | Connect the enthalpy | Milliammeter reading |

Air Sensor) | | sensor terminal 1 to | should be between |

| | terminal 1 on the motor. | 3 and 24 mA if the |

| 2. | Connect the positive ter- | sensor is operating |

| | minal of a DC milliam- | correctly. If the read- |

| | meter to terminal S of | ing is 0 mA, the |

| | the sensor. | sensor is either |

| 3. | Connect the negative | wired backward or is |

| | terminal of a DC milliam- | defective. |

| | meter to terminal SR of | |

| | the enthalpy board. | |

BASIC CHECK Ð Refer to Fig. 64 for control board com- ponent identi®cation.

NOTE: All plugs (except P1) are labeled for easy identi®- cation. Plug P1 can be identi®ed by its orange color.

1.Turn unit power off. Disconnect plug P1 from control board.

2.Turn unit power on and check voltage across Pin R and Pin C at plug P1. If voltage reads 18 to 30 v, skip to Step 5.

3.Turn unit power off. Disconnect plug P3.

4.Turn unit power on and measure voltage across wires on plug P3, Pins 1 and 2 (wires coming from the unit). If voltage reads 18 to 30 v, there is either a bad connection between plug P3 and control board, or the control board is defective. Verify the connection at this point and pro- ceed to Step 5. If there is no voltage, check the circuit breaker and transformer in the 24-v control circuit of the unit.

5.Turn unit power off and disconnect plug P4 from the con- trol board.

6.Switch scale on meter to read 115 v.

7.Turn unit power on and check voltage across Pin 6 on plug 4 and unit ground (wires coming from the unit). If voltage reads 104 to 122 v, there is adequate power avail- able to the board. Verify connection at this point and pro- ceed to Step 8. If there is no voltage, check the circuit breaker and transformer in the 115-v control circuit of the unit.

8.After verifying that 24-v and 115-v supply power is avail- able to the control board, turn unit power off and recon- nect plugs P1, P3, and P4. Proceed to Detailed Check section below.

DETAILED CHECK

NOTE: Plug P1 must be disconnected in order to perform any of the troubleshooting steps detailed in this section. To save time, reconnect plug P1 only after you have completed all of the required troubleshooting.