IMPORTANT: All alcohols should be

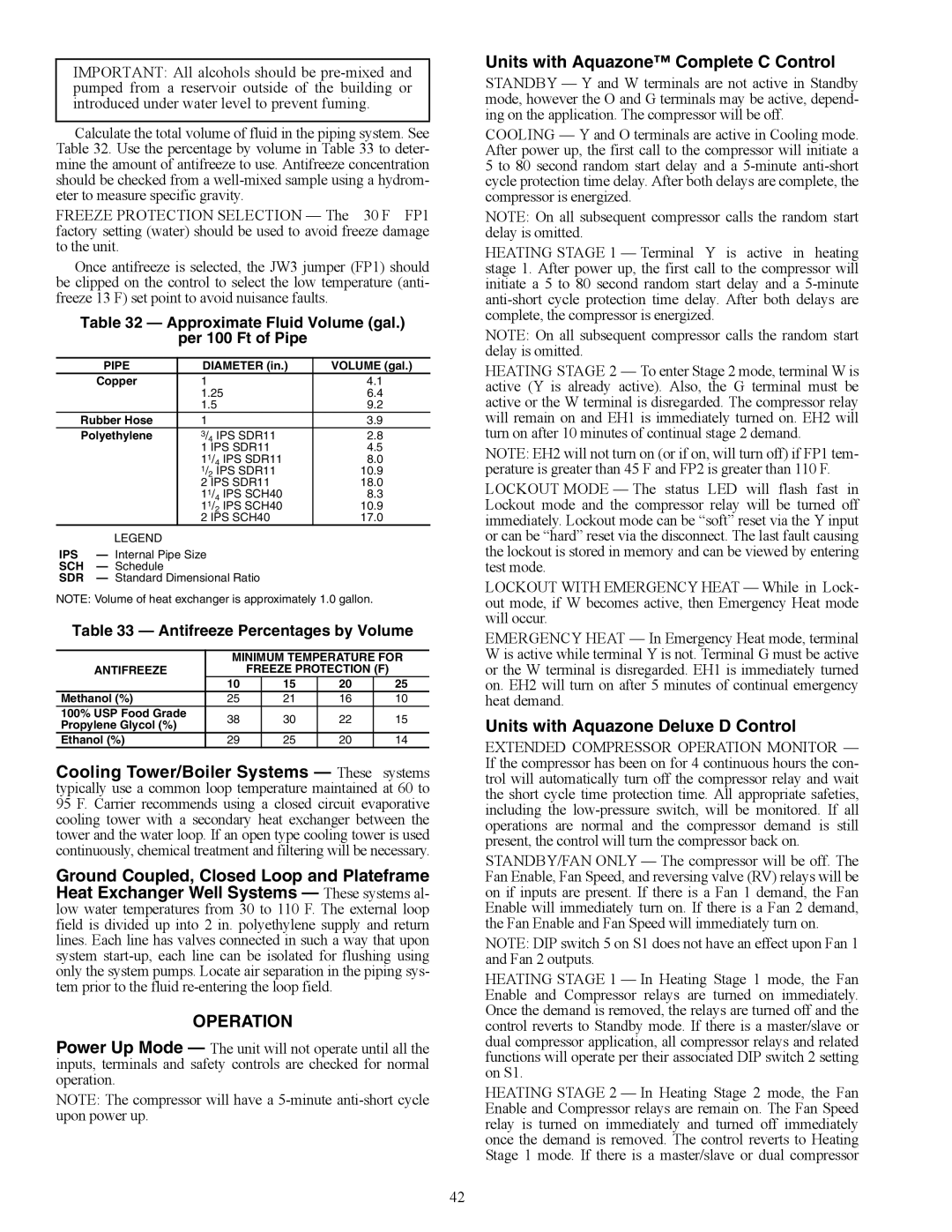

Calculate the total volume of fluid in the piping system. See Table 32. Use the percentage by volume in Table 33 to deter- mine the amount of antifreeze to use. Antifreeze concentration should be checked from a

FREEZE PROTECTION SELECTION — The 30 F FP1 factory setting (water) should be used to avoid freeze damage to the unit.

Once antifreeze is selected, the JW3 jumper (FP1) should be clipped on the control to select the low temperature (anti- freeze 13 F) set point to avoid nuisance faults.

Table 32 — Approximate Fluid Volume (gal.)

per 100 Ft of Pipe

PIPE | DIAMETER (in.) | VOLUME (gal.) |

Copper | 1 | 4.1 |

| 1.25 | 6.4 |

| 1.5 | 9.2 |

Rubber Hose | 1 | 3.9 |

Polyethylene | 3/4 IPS SDR11 | 2.8 |

| 1 IPS SDR11 | 4.5 |

| 11/4 IPS SDR11 | 8.0 |

| 1/ IPS SDR11 | 10.9 |

| 2 | 18.0 |

| 2 IPS SDR11 | |

| 11/4 IPS SCH40 | 8.3 |

| 11/2 IPS SCH40 | 10.9 |

| 2 IPS SCH40 | 17.0 |

LEGEND

IPS — Internal Pipe Size

SCH — Schedule

SDR — Standard Dimensional Ratio

NOTE: Volume of heat exchanger is approximately 1.0 gallon.

Table 33 — Antifreeze Percentages by Volume

| MINIMUM TEMPERATURE FOR | |||||

ANTIFREEZE |

| FREEZE PROTECTION (F) |

| |||

| 10 |

| 15 | 20 |

| 25 |

Methanol (%) | 25 |

| 21 | 16 |

| 10 |

100% USP Food Grade | 38 |

| 30 | 22 |

| 15 |

Propylene Glycol (%) |

|

| ||||

|

|

|

|

|

| |

Ethanol (%) | 29 |

| 25 | 20 |

| 14 |

Cooling Tower/Boiler Systems — These systems typically use a common loop temperature maintained at 60 to 95 F. Carrier recommends using a closed circuit evaporative cooling tower with a secondary heat exchanger between the tower and the water loop. If an open type cooling tower is used continuously, chemical treatment and filtering will be necessary.

Ground Coupled, Closed Loop and Plateframe Heat Exchanger Well Systems — These systems al- low water temperatures from 30 to 110 F. The external loop field is divided up into 2 in. polyethylene supply and return lines. Each line has valves connected in such a way that upon system

OPERATION

Power Up Mode — The unit will not operate until all the inputs, terminals and safety controls are checked for normal operation.

NOTE: The compressor will have a

Units with Aquazone™ Complete C Control

STANDBY — Y and W terminals are not active in Standby mode, however the O and G terminals may be active, depend- ing on the application. The compressor will be off.

COOLING — Y and O terminals are active in Cooling mode. After power up, the first call to the compressor will initiate a 5 to 80 second random start delay and a

NOTE: On all subsequent compressor calls the random start delay is omitted.

HEATING STAGE 1 — Terminal Y is active in heating stage 1. After power up, the first call to the compressor will initiate a 5 to 80 second random start delay and a

NOTE: On all subsequent compressor calls the random start delay is omitted.

HEATING STAGE 2 — To enter Stage 2 mode, terminal W is active (Y is already active). Also, the G terminal must be active or the W terminal is disregarded. The compressor relay will remain on and EH1 is immediately turned on. EH2 will turn on after 10 minutes of continual stage 2 demand.

NOTE: EH2 will not turn on (or if on, will turn off) if FP1 tem- perature is greater than 45 F and FP2 is greater than 110 F.

LOCKOUT MODE — The status LED will flash fast in Lockout mode and the compressor relay will be turned off immediately. Lockout mode can be “soft” reset via the Y input or can be “hard” reset via the disconnect. The last fault causing the lockout is stored in memory and can be viewed by entering test mode.

LOCKOUT WITH EMERGENCY HEAT — While in Lock- out mode, if W becomes active, then Emergency Heat mode will occur.

EMERGENCY HEAT — In Emergency Heat mode, terminal W is active while terminal Y is not. Terminal G must be active or the W terminal is disregarded. EH1 is immediately turned on. EH2 will turn on after 5 minutes of continual emergency heat demand.

Units with Aquazone Deluxe D Control

EXTENDED COMPRESSOR OPERATION MONITOR — If the compressor has been on for 4 continuous hours the con- trol will automatically turn off the compressor relay and wait the short cycle time protection time. All appropriate safeties, including the

STANDBY/FAN ONLY — The compressor will be off. The Fan Enable, Fan Speed, and reversing valve (RV) relays will be on if inputs are present. If there is a Fan 1 demand, the Fan Enable will immediately turn on. If there is a Fan 2 demand, the Fan Enable and Fan Speed will immediately turn on.

NOTE: DIP switch 5 on S1 does not have an effect upon Fan 1 and Fan 2 outputs.

HEATING STAGE 1 — In Heating Stage 1 mode, the Fan Enable and Compressor relays are turned on immediately. Once the demand is removed, the relays are turned off and the control reverts to Standby mode. If there is a master/slave or dual compressor application, all compressor relays and related functions will operate per their associated DIP switch 2 setting on S1.

HEATING STAGE 2 — In Heating Stage 2 mode, the Fan Enable and Compressor relays are remain on. The Fan Speed relay is turned on immediately and turned off immediately once the demand is removed. The control reverts to Heating Stage 1 mode. If there is a master/slave or dual compressor

42