| Supply Air |

|

| |

|

| Building |

| |

| Flexible | Loop |

| |

| Connection |

|

| |

|

| Water |

| |

Return |

| Out |

| |

|

|

| ||

Air |

| Water |

| |

|

|

| ||

|

| In | Balancing Valve | |

| Stainless steel | |||

| braid hose | accessory) | ||

| with integral |

| ||

| “J” swivel |

| ||

| Low Pressure | |||

| accessory) | |||

| Drop Water | |||

Power |

|

| ||

|

| Control Valve | ||

Thermostat |

|

| (optional) | |

|

| |||

Wiring |

|

| accessory) | |

|

| Ball Valve with optional | ||

| Compressor | integral P/T plug | ||

| (typical for supply and | |||

| Access Panel | |||

return piping) | ||||

| ||||

| accessory) |

| ||

NOTE: Ball valve with integral pressure temperature plug recommended.

Fig. 5 — Typical Vertical Installation — 50PSV Unit

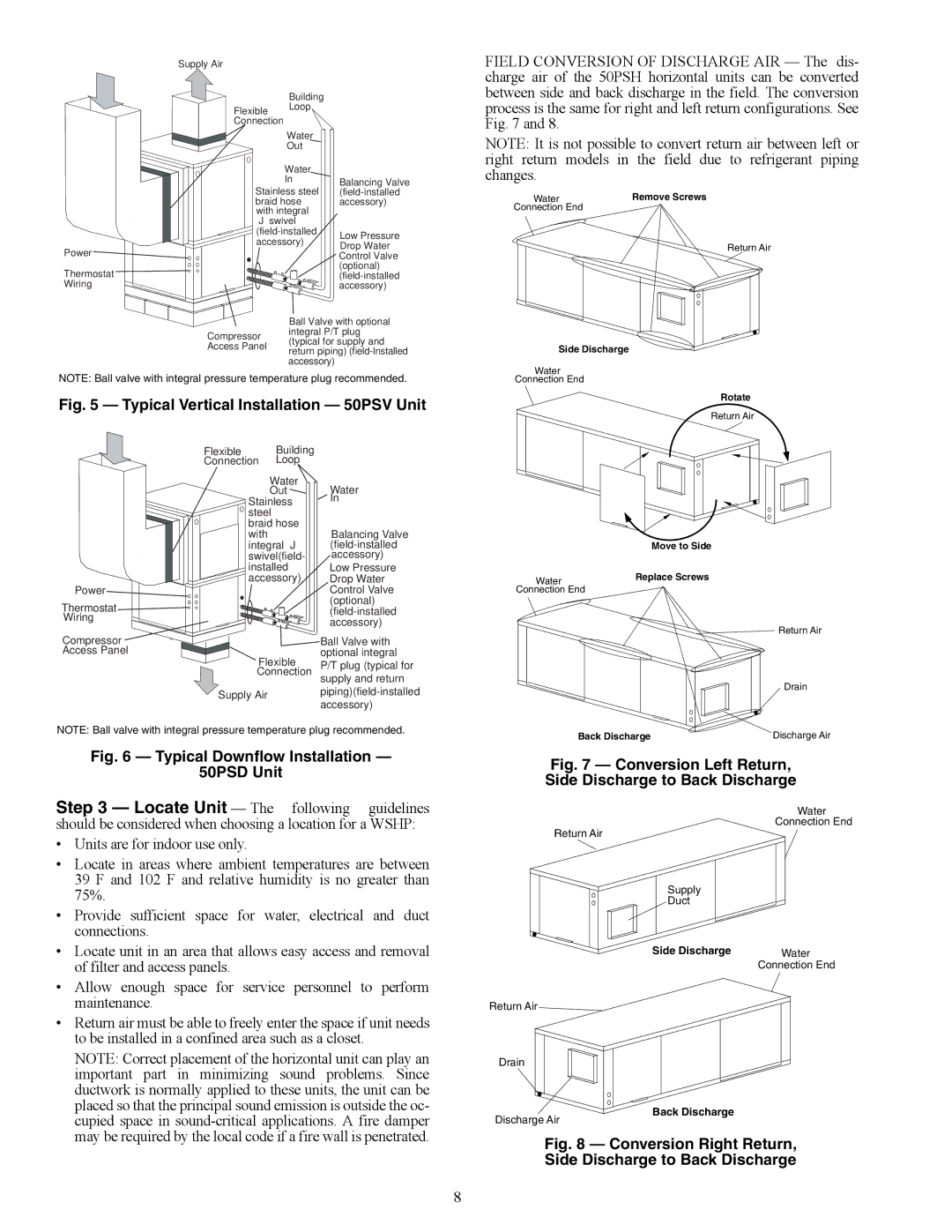

FIELD CONVERSION OF DISCHARGE AIR — The dis- charge air of the 50PSH horizontal units can be converted between side and back discharge in the field. The conversion process is the same for right and left return configurations. See Fig. 7 and 8.

NOTE: It is not possible to convert return air between left or right return models in the field due to refrigerant piping changes.

Water | Remove Screws |

Connection End |

|

Return Air

Side Discharge

Water

Connection End

Rotate

Return Air

Return

Air

Power

Thermostat

Wiring

Compressor

Access Panel

A50-7729

Flexible | Building |

| |

Connection | Loop |

| |

| Water | Water | |

| Out | ||

Stainless | In | ||

steel |

| ||

braid hose |

| ||

with |

| Balancing Valve | |

integral ”J” | |||

swivel(field- | accessory) | ||

installed | Low Pressure | ||

accessory) | Drop Water | ||

|

| Control Valve | |

|

| (optional) | |

|

| ||

|

| accessory) | |

|

| Ball Valve with | |

Flexible | optional integral | ||

P/T plug (typical for | |||

Connection | |||

|

| supply and return | |

Supply Air | ||

accessory) | ||

|

| Move to Side |

Water | Replace Screws |

| |

Connection End |

|

Return Air

Drain

NOTE: Ball valve with integral pressure temperature plug recommended.

Fig. 6 — Typical Downflow Installation —

50PSD Unit

Step 3 — Locate Unit — The following guidelines should be considered when choosing a location for a WSHP:

•Units are for indoor use only.

•Locate in areas where ambient temperatures are between 39 F and 102 F and relative humidity is no greater than 75%.

•Provide sufficient space for water, electrical and duct connections.

•Locate unit in an area that allows easy access and removal of filter and access panels.

•Allow enough space for service personnel to perform maintenance.

•Return air must be able to freely enter the space if unit needs to be installed in a confined area such as a closet.

NOTE: Correct placement of the horizontal unit can play an important part in minimizing sound problems. Since ductwork is normally applied to these units, the unit can be placed so that the principal sound emission is outside the oc- cupied space in

A50-6256

Back Discharge | Discharge Air |

Fig. 7 — Conversion Left Return,

Side Discharge to Back Discharge

Water

Connection End

Return Air

Supply

Duct

Side Discharge | Water |

| Connection End |

Return Air![]()

Drain |

|

Discharge Air | Back Discharge |

Fig. 8 — Conversion Right Return,

Side Discharge to Back Discharge

8