NOTES:

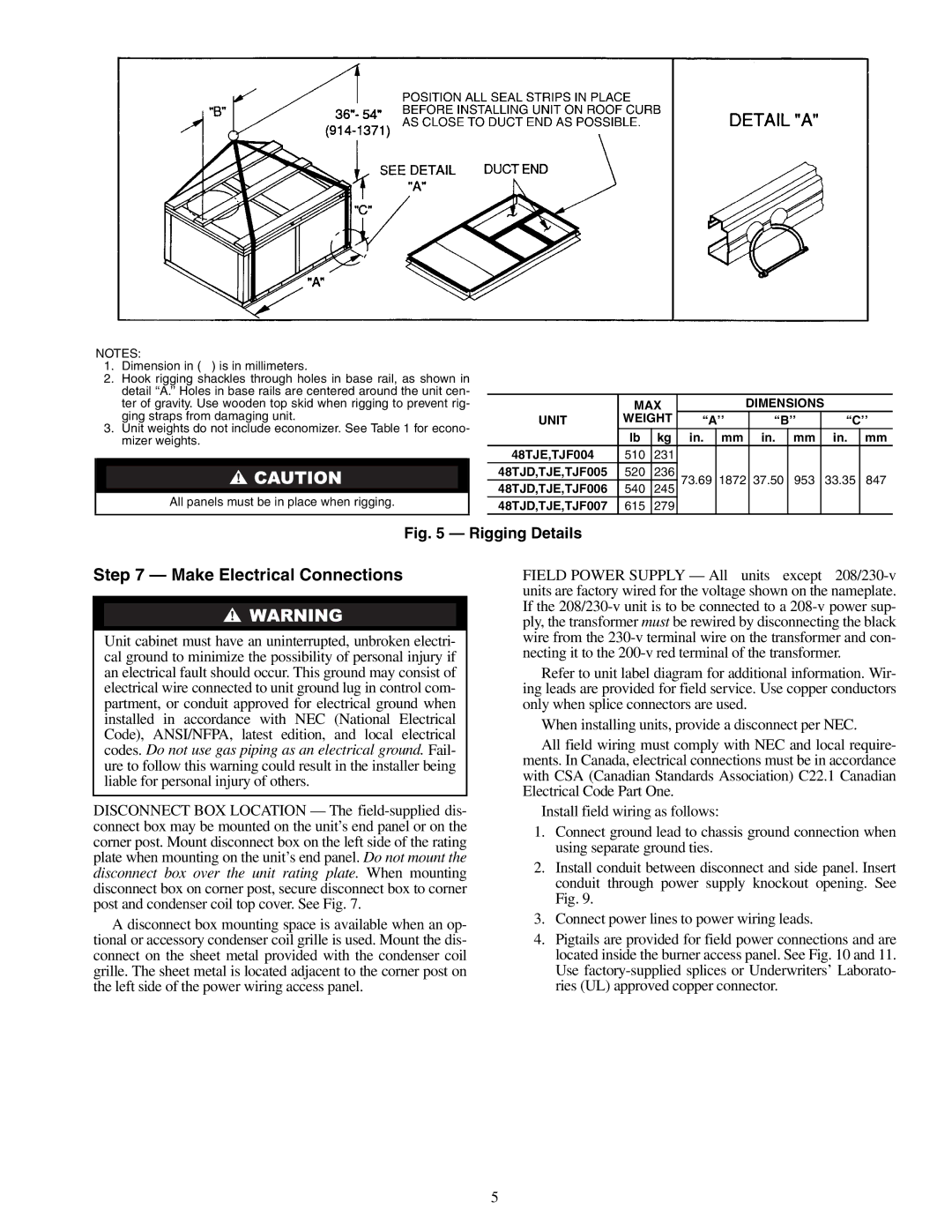

1. Dimension in ( ) is in millimeters.

2.Hook rigging shackles through holes in base rail, as shown in detail ‘‘A.’’ Holes in base rails are centered around the unit cen- ter of gravity. Use wooden top skid when rigging to prevent rig- ging straps from damaging unit.

3.Unit weights do not include economizer. See Table 1 for econo- mizer weights.

All panels must be in place when rigging.

| MAX |

| DIMENSIONS |

|

| ||||

UNIT | WEIGHT | ‘‘A’’ | ‘‘B’’ |

| ‘‘C’’ | ||||

| lb | kg | in. | mm | in. | mm |

| in. | mm |

48TJE,TJF004 | 510 | 231 |

|

|

|

|

|

|

|

48TJD,TJE,TJF005 | 520 | 236 | 73.69 | 1872 | 37.50 | 953 |

| 33.35 | 847 |

48TJD,TJE,TJF006 | 540 | 245 |

| ||||||

48TJD,TJE,TJF007 | 615 | 279 |

|

|

|

|

|

|

|

Fig. 5 — Rigging Details

Step 7 — Make Electrical Connections

Unit cabinet must have an uninterrupted, unbroken electri- cal ground to minimize the possibility of personal injury if an electrical fault should occur. This ground may consist of electrical wire connected to unit ground lug in control com- partment, or conduit approved for electrical ground when installed in accordance with NEC (National Electrical Code), ANSI/NFPA, latest edition, and local electrical codes. Do not use gas piping as an electrical ground. Fail- ure to follow this warning could result in the installer being liable for personal injury of others.

FIELD POWER SUPPLY — All units except

Refer to unit label diagram for additional information. Wir- ing leads are provided for field service. Use copper conductors only when splice connectors are used.

When installing units, provide a disconnect per NEC.

All field wiring must comply with NEC and local require- ments. In Canada, electrical connections must be in accordance with CSA (Canadian Standards Association) C22.1 Canadian Electrical Code Part One.

DISCONNECT BOX LOCATION — The

A disconnect box mounting space is available when an op- tional or accessory condenser coil grille is used. Mount the dis- connect on the sheet metal provided with the condenser coil grille. The sheet metal is located adjacent to the corner post on the left side of the power wiring access panel.

Install field wiring as follows:

1.Connect ground lead to chassis ground connection when using separate ground ties.

2.Install conduit between disconnect and side panel. Insert conduit through power supply knockout opening. See Fig. 9.

3.Connect power lines to power wiring leads.

4.Pigtails are provided for field power connections and are located inside the burner access panel. See Fig. 10 and 11. Use

5