Page

Declaration of Conformity

Important Safety Instructions

Lärmemission kleiner 70dBA

Wichtige Sicherheitsanweisungen

Sicherheitshinweis

General Precautions

Safety Precautions Which should be Strictly Observed

Page

Precautions for Installation

To prevent injuries and associated damages

Precautions for Handling

HOT Area

Daily Maintenance

Cleaning the print head

Table of Contents

Maintenance and Service Print Control Functions

168

148

154

160

199

Inhalt

182

195

204

209

211

General Outline

Features

Unpacking

Model Classification

Basic Specifications

Code 39, Code 128, CODABAR, Code

Basic Specifications

Recommended Paper

Print Paper Specifications

Print Position and Barcode Printing

Roll paper width 80 mm provided

Printing Area

Paper

Used Paper Form

Sensor Position and Cutter Position

CBM1000S

Outer Appearance and Component Parts

CBM1000A / CBM1000D

Operation

Connecting the AC Adapter and AC Power Cord

Interface cable to the host computer

Connecting Interface Cables

Turn off the power of the printer. As

Interface connector

Connecting the Drawer Kick-Out Connector

On the printer cover until a click is Heard

Setting / Replacing Paper Rolls

Turn on the printer

Check the winding direction

Page

Adjusting the Paper Near-end Sensor

Using 58 mm Wide Paper Rolls

Turn off the power of the printer

Removing Paper Jams

Cleaning the Print Head

Error indication

Operation Panel and Error Indication

Power lamp Green

Error lamp Red

Control Functions

Feed switch

Feed switch and Power switch

Buzzer-on Timing

Starting hexadecimal dump

Hexadecimal Dump

Setting DIP Switches

Location of DIP Switches

To access the DIP switches, follow these steps

Table for Setting DIP Switches

DIP switch

Print density DIP switch

Selection of Character Code tables DIP switch

Baud rate DIP switch

Outline

Reverse Mode Printer → Host communication

Parallel Interface

Bidirectional Parallel Interface IEEE1284

Dkstatus

Connector Pin Configuration

Output signals from the printer

Description of Input and Output Signals

Input and Output Signals

Input signals to the printer

Input and output conditions

Electrical Characteristics

Input signal level nStrobe, Data

Output signal level

Data input and print timing

Timing Chart Compatibility Mode

Data Reception Control

Buffering

Serial Interface

Specifications

Connector Pin Configuration

GND

DTR, RTS

DSR

Init

Overrun error

Error Detection

Framing error

Parity error

RS-232C circuit

Drawer Kick-Out drive signal

Specifications of Drawer Kick-Out Connector

Specifications of the Power Connector

Pin configuration of Power connector

Drive Circuit

Northern America Other Areas

Maintenance and Service

Command List

Command Function Mode Code

Print Control Functions

ESC \

Function Mode Code

Command relative to NV memory

Label Control

Command Details

See Also

Command Details

Print Results

See Also Sample Program

Standard Mode

Mode

Print Result

Can

DLE EOT n

Range Outline

Example

Page

See Also

DLE ENQ n

Details

DLE DC4 n m t

Execution Result Buzzer sounds for approx ms

ESC FF

ESC SP n

Default See Also

Lprint Aaaaa + CHR$&HA

ESC ! n

Lprint CHR$&HA END

ESC $ n1 n2

Lprint CHR$&HA

Gosub Setchr Data

ESC % n

ESC & s n m a p s×a m-n+1

Font a

ESC * m n1 n2 d k

IMG1

ESC n

ESC

ESC 3 n

ESC = n

ESC ? n

Function Code Outline Sample Program Print Results

ESC @

ESC D n k NUL

ESC E n

ESC G n

ESC J n

ESC L

ESC M n

ESC R n

ESC S

ESC T n

ESC V n

Default Sample Program

ESC W xL xH yL yH dxL dxH dyL dyH

CAN, ESC L, ESC T, GS P

ESC \ nL nH

ESC a n

ESC c 3 n

ESC c 4 n

ESC c 5 n

ESC d n

ESC p m n1 n2

’ μ ←⎯ n =

Function Code Range Outline

Default Sample Program Print Results

GS ! n

Horizontal Magnification

Vertical Magnification

Default See Also

See Also ESC $, ESC T, ESC W, ESC \, GS P, GS \

GS $ nL nH

GS * n1 n2 d n1×n2×8

Next I Next J Return

Definition

GS a pL pH n m

GS / m

Specifying starting/ending macro definition

GS B n

GS H n

104

GS I n

GS L nL nH

GS P, GS W

GS P x y

1DH56Hm

GS W nL nH

GS L, GS P

GS \ nL nH

GS n1 n2 n3

GS a n

Online status Offline status Unused Cover closed Cover open

Appendix

GS f n

Selecting bar code height

D1 ...... dn

D1 ..... dk NUL

For

For Standard Mode

Default Initial value is not defined

For page Mode

UPC-A

Description of Bar Codes For print examples, refer to

Ascii

This bar code consists of 103 bar code characters

FNC4

Special characters

Description of Bar Codes

GS r n

When the serial interface is used

DLE EOT, GS a, Identification of Send Status

GS v 0 m xL xH yL yH d1...dk

When xL+xH × 256=

GS w n

Range

FS g3 m a1 a2 a3 a4 nL nH d1…dk

Reference

FS g4 m a1 a2 a3 a4 nL nH

FS g3

P n m

Page

Q n xL xH yL yH d1…dk 1… xL xH yL yH d1…dk n

Page

Related Commands FS p

GS FF

GS a m n

GS C0 m n

Default See Also Sample Program

GS C1 n1 n2 n3 n4 n5 n6

Sample Program Print Result

GS C2 n1 n2

GS C n1 n2 n3 n4 n5

GS I n1L n1H n2L n2H

GS c

Character Codes Table

Code

Codepage Katakana Japanese

Codepage PC850 Multilingual Codepage PC860 Portuguese

Codepage PC863 Canadian-French Codepage PC865 Nordic

Codepage PC852 Eastern Europe Codepage PC866 Russian

Codepage PC857 Turkish Windows Codepage

International Character Codes Table

Appendix 1. page Mode

Switching Between Standard Mode and page Mode

Overview

Mapping of print data in the print area

Mapping Positions for Print Data

Mapping Position for Character Data

Example of the Use of page Mode

158

159

Parallel Interface Communication Modes

Interfacing Phases

Negotiation Procedure

Negotiation

Overview

Precautions

Data Communication from Printer to Host

Nibble Mode

Byte Mode

Termination

Device ID

Page

Identification of Send Status

Appendix 3.IDENTIFICATION of Send Status

15.1 CBM1000S

Appendix 4. Outline Drawing

15.2 CBM1000A / CBM1000D

AC Adapter 31AD

CPU

Appendix 5. Block Diagram

German

Allgemeine Vorsichtsmassnahmen

Warnung

Warnung

Vorsichtsmassnahmen FÜR DIE Installation

Vorsichtsmassnahmen FÜR DIE Handhabung

Heisser Bereich

Tägliche Wartungsarbeiten

Reinigen des Druckkopfs

Anschließen des Netzteils und Netzkabels

Betrieb

183

Die entsprechende Schnittstelle an

Anschließen der Schnittstellenkabel

Schalten Sie die Stromversorgung

Richtig aus, und schließen Sie es an

Anschließen des Drawer Kickout-Steckers

Einlegen / Auswechseln von Papierrollen

Schalten Sie den Drucker ein

Überprüfen Sie die Wickelrichtung

187

Justieren des Papierende-Sensors

Beseitigen von Papierstaus

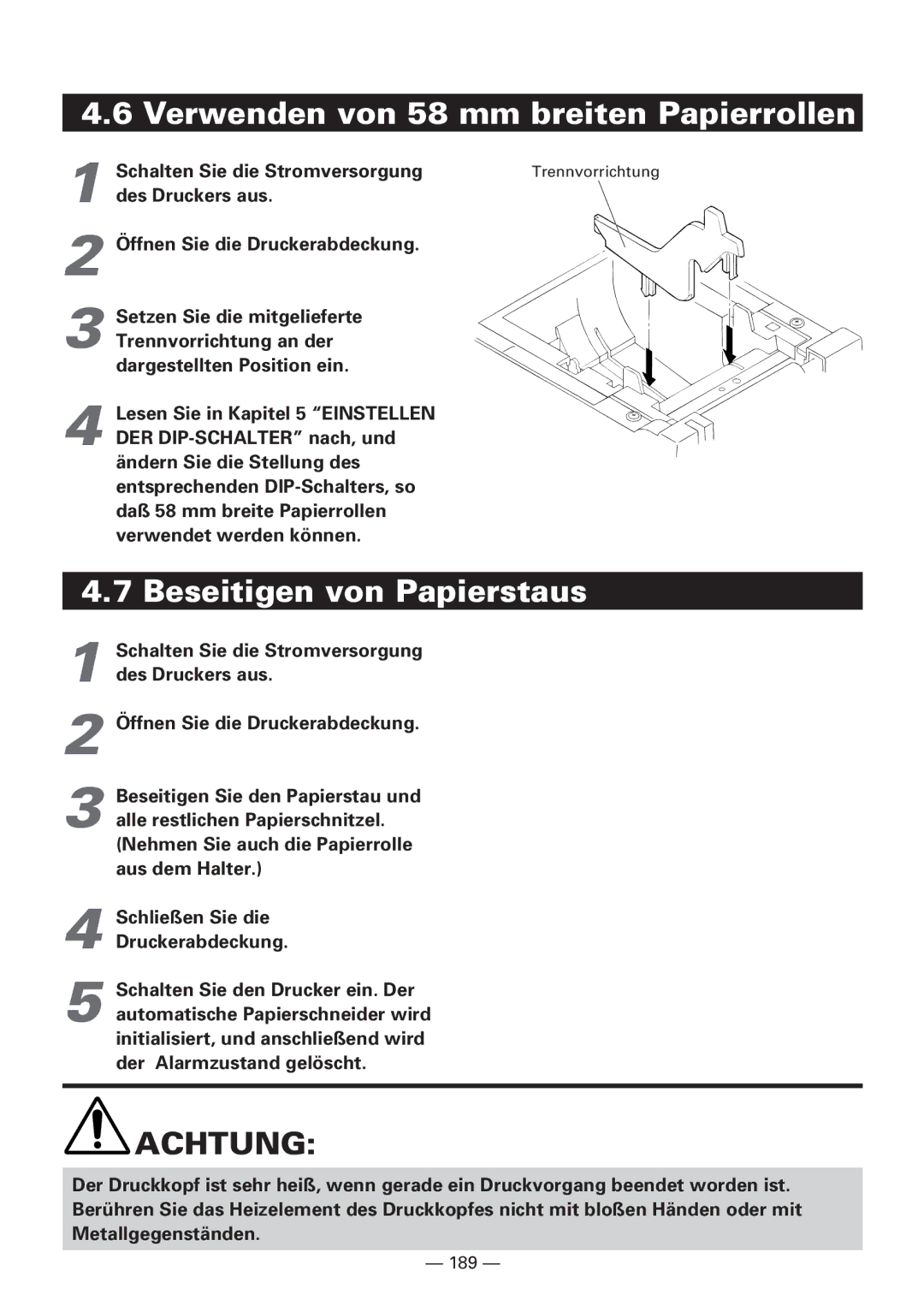

Verwenden von 58 mm breiten Papierrollen

Reinigen des Druckkopfes

Fehleranzeige

Anzeigeleuchte Power Grün

Anzeigeleuchte Error Rot

Bedienungsfeld und Fehleranzeige

Fehlerbeschreibung

Taste Feed und Schalter Power

Taste Feed

Summer-Hinweistöne

=== Hexadecimal Dump ===

Hexdump

Funktion zur Erstellung eines hexadezimalen Speicherauszugs

Beispiel eines Hexdump

Position der DIP-Schalter

Einstellen DER DIP-SCHALTER

DIP-Schaltertabelle

DIP-Schalter

Druckdichte DIP-Schalter

Wählen der Zeichencodetabellen DIP-Schalter

Baud-Rate DIP-Schalter

Kurzbeschreibung

Parallele Schnittstelle

Bidirektionale parallele Schnittstelle IEEE1284

Reverse-Modus Drucker → Hostkommunikation

Belegung der Anschlußstifte

Stromversorgungssignal

Eingangs- und Ausgangssignale

Druckereingangssignale

Druckerausgangssignale

Eingangs- und Ausgangsbedingungen

Eingangssignalpegel nStrobe, Data

Ausgangssignalpegel

Elektrische Kenndaten

Timing von Dateneingang und Datendruck

Timing-Tabelle KompatibilitätsModus

Datenempfangssteuerung

Datenpufferspeicher

Technische Daten

Serielle Schnittstelle

Belegung der Anschlußstifte

Beschreibung der Eingangs- und Ausgangssignale

Paritätsfehler

Fehlererkennung

Pufferung

DÜ-Blockfehler

RS-232C-Schaltkreis

Technische Daten des Drawer KickOut-Anschlusses

Drawer KickOut-Treibersignal

Technische Daten des Stromanschlusses

Treiberschaltung

Stiftbelegung des Netzanschlusses

Nordamerika Sonstige Länder

Wartung UND Kundendienst

Information Systems Division Head Office

ACHTUNG:

ACHTUNG: