113.248320

Save This Manual For Future Reference

113.248440113.248510

Table of Contents

Keep Guards in Place

Know Your Power Tool Ground ALL Tools

Keep Work Area Clean

USE Recommended Accessories Never Stand on Tool

Before Each USE

Additional safety instructions for band saw

Before Using the SAW

When Installing or Moving the SAW

Before Sanding

Accessories

Whenever SAW is Running

Glossary of terms for woodworking

Power Supply

25 Ft 26 50 Ft 100 Ft

Motor Safety Protection

Wire Sizes

Sawdust from interfering with normal motor ventila- tion

General information

Unpacking and checking contents

Description QTY

Loose Parts

Pan Hd. Screw 10-32 x

List of Loose Parts in BAG #507968

Truss Head Screw 1/4-20x12

List of Loose Parts in BAG #508014

Nuts Support Bracke Leveling Foot

Assembly and alignment

Attaching LEG SET

Model 113.24821 O

Description Qty Truss Head

Assembling Cabinet

Model

\ ,/o

From loose parts bag find the following hard

Mounting the SAW to the Cabinet

Ware

Front

Find the following parts

Model 113.248210 only

Attaching the Handwheel

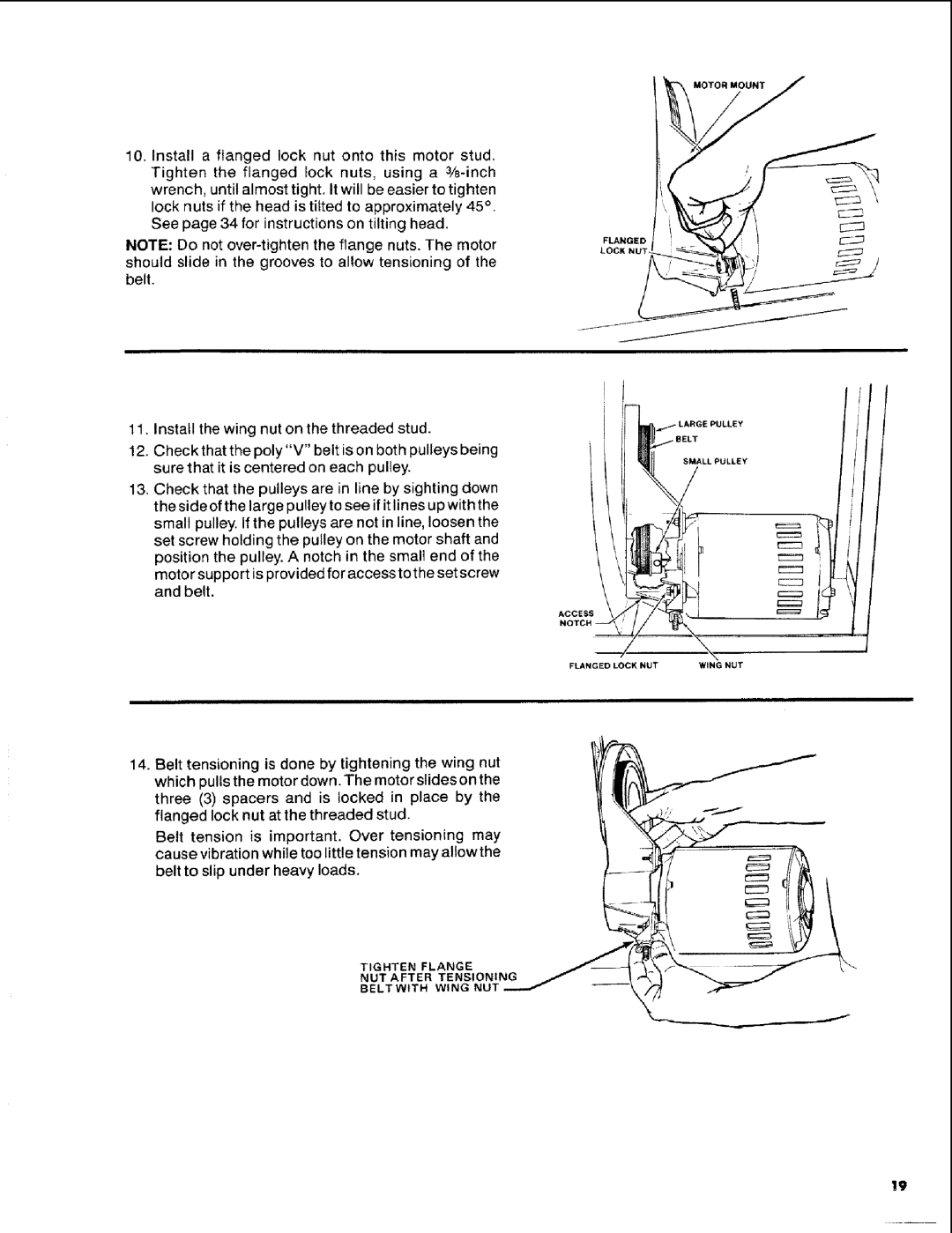

Mounting the Motor

Models 113.248440,

Tighten Flange NUT After Tensioning Beltwith Wing NUT

Steps are Completed

Connecting the Motor

Selecting Blade Speed

Recommended Speed Settings

Changing Speed Settings

Model 113.248320, 113.248440

Attaching Trim Caps

MODELS113.248210an¢

Getting to know your band saw

Model 113.248440 & 113.248510 on LY

Location and function of the electronic indicator system

Open Battery Open

Battery Cover

3000

Using the Electronic Indicator System

Function Keys

Read-out Indicates correct tension for

Jrt,t

Installing the Blade

Upperblade tl t

GU,DEsuPPO.TIIl-r L

Aligning the Blade and Blade Guide Assemblies

Model 113.248440

Blade Guide

4-20 8 hex washer Head thread forming Screws

Mounting Front

Turn front table over. Locate the two 2 latch

Springs, two 2 alignment springs, and the four

Head Capscrew

Squaring the Blade to the Table

Adjusting Front Table

Location and function of controls

ON-OFF Switch

Model 113.248210 & 113,248320

Adjusting Bevel Lock Knob

Operation Recommended Blade Size

Basic band saw operation

Sawdust Collection

Circle Cutting

Installing the Sanding Belt

Installing Sanding Attachment

Adjusting Band SAW Bevel Travel

Maintenance

Adjusting the Upper Blade Guide Travel

Light Bulb

Outlet Before Trouble Shooting Your Band SAW/SANDER

Remedy

Trouble shooting--motor

Trouble

Probable Cause

Problem

Trouble shooting -- electronics

Probable Cause Suggested Corrective Action

113.2485t

Trouble shooting ---electronics

Suggested Corrective Action

Leg

Repair parts

Parts List for Craftsman 12-INCH Band SAW

Key Part Description

Page

Key

Drive Assembly Parts

Model NOS .248210,113.248320, 113.248440

OMode1113.248320 Only ==Model113.248510 Only

Base Assembly

Model NOS .248210,113.248320,113.248440

9414202

Bevel Drive and Motor Mount Assembly Parts

Screw, Truss Hd /4-20 x 1/2

Parts List for Craftsman 12-INCH Electronic Band SAW

Page

Part Numberpartdescription Model Name of Item

Airs