Light Bulb

To replace the light bulb remove the front cover. Use a phillips screwdriver to remove the lens and replace

the bulb. The light bulb is a 25 watt bayonet mount bulb.

Motor

Frequently blow or vacuum out any sawdust from

the motor, Follow lubrication instruction on the motor label.

WARNING: TO AVOID EYE INJURY FROM BLOW-

ING DEBRIS, WEAR SAFETY GOGGLES WHEN

BLOWING OUT SAWDUST.

WARNING: TO AVOID ELECTROCUTION OR FIRE,

IMMEDIATELY REPLACE A WORN, CUT, OR

DAMAGED POWER CORD.

Lubrication

All of the ball bearings are packed with grease at the factory. They require no further lubrication.

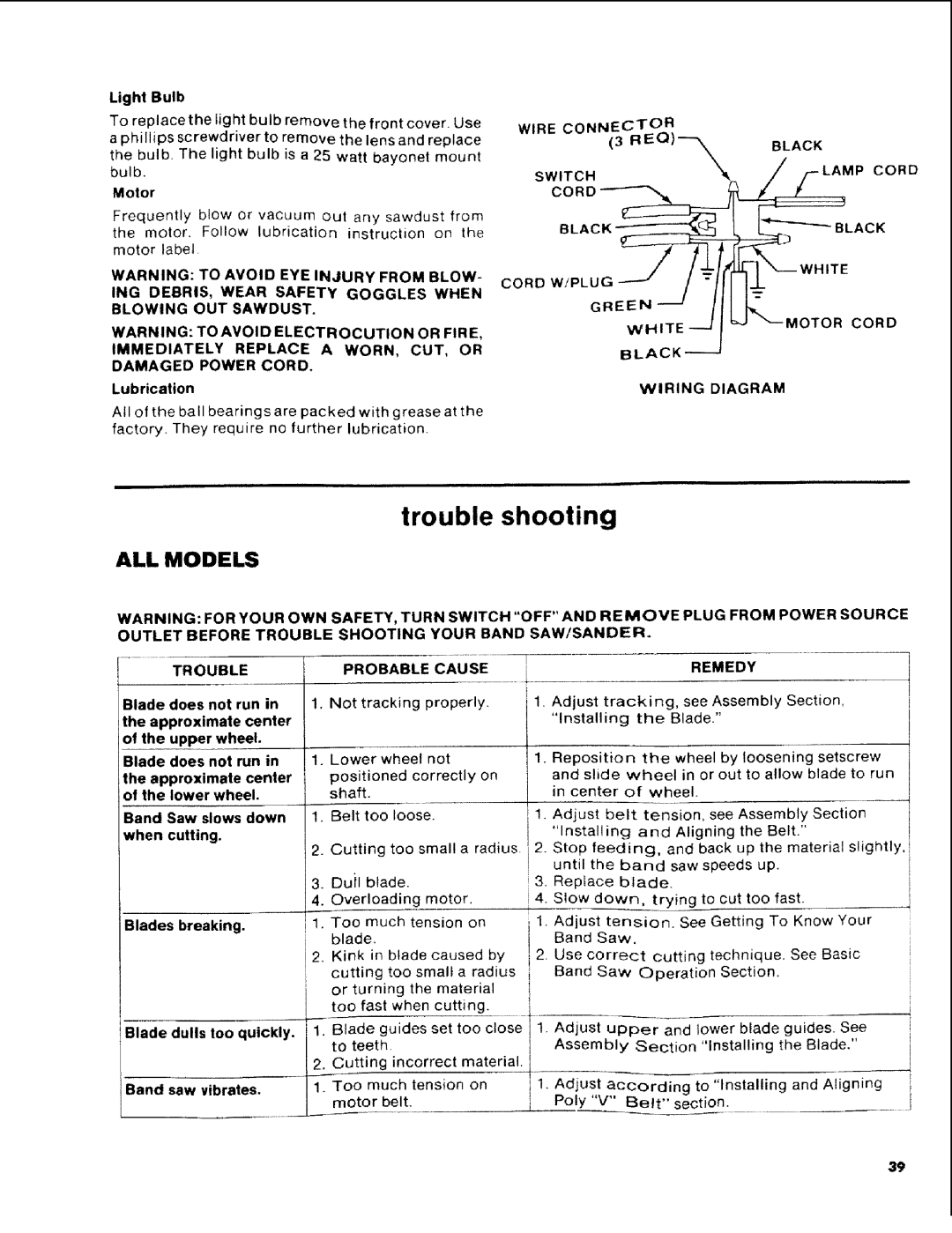

WIRE CONNECTOR

(3 | BLACK |

SWITCH"_k / F

// _ r_JJ.]1

CORD W!PLUG_ | / " I I€ |

BLACK_

WIRING DIAGRAM

trouble shooting

ALL MODELS

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH "OFF" AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE TROUBLE SHOOTING YOUR BAND SAW/SANDER.

TROUBLE

PROBABLE CAUSE | REMEDY |

Blade does not run in the approximate center of the upper wheel. Blade does not run in

the approximate center of the lower wheel.

Band Saw slows down when cutting.

Blades breaking.

I

1. Not tracking properly.

1.Lower wheel not positioned correctly on shaft.

1, Belt too loose.

2.Cutting too small a radius

3.Duil blade.

4.Overloading motor,

1.Too much tension on blade.

2.Kink in blade caused by cutting too small a radius or turning the material too fast when cutting.

1. | Adjust tracking, | see | Assembly | Section, | |||

I | "Installing | the | Blade." |

|

|

|

|

1, | Reposition | the | wheel | by | loosening | setscrew | |

| and slide | wheel | in or | out | to allow | blade to run | |

| in center | of wheel. |

|

|

|

| |

1, Adjust belt tension, see Assembly Section

"Installing and Aligning the Belt."

2.Stop feeding, and back up the material slightly, until the band saw speeds up.

3.Replace blade.

i 4. Slow down, trying to cut too fast.

1.Adjust tension. See Getting To Know Your Band Saw,

2.Use correct cutting technique. See Basic

Band Saw Operation Section.

Blade dulls too quickly.

Band saw vibrates.

Blade | guides set | too close | 1. | Adjust upper | and | lower blade | guides. See |

| ||

to teeth. |

|

| Assembly | Section | "Installing | the Blade." |

| |||

2. Cutting | incorrect | material. |

|

|

|

|

|

|

|

|

Too much tension | on | Adjust | according |

| to "Installing | and Aligning | {r | |||

motor | belt. |

|

| Poly | "V" | E_e_t" | section. |

|

| |

39