Product

Rules Operating

Instructions before first use of this

Rrftsmrn TABLESAW315.228110

Full ONE Year Warranty on Craftsman Table SAW

3CRAFTSMANTABLESAW315.228110

BladeCheckandBladeGuardAssembly

21-33

Safety Alert Symbol

Symbol

Read ALL Instructions

Do not USE in Dangerous Environ

Never USE this Tool in AN Explosive

USE a Support for the Sides and Back

Before Making a CUT, be sure all adjust- merits are secure

Save These INSTRUCTIONS. Refer to them

Always Push the Workpiece never pull it toward the saw

Extension Cords

Speed and Wiring

Electrical Connection

Grounding Instructions

Rip Cut

Resin

Saw Blade Path

Set

Wide Table Kit

Do not USE 7 in. Wobble Dadoes

RRAFTSMIIN TABLESAW315.228110

Following items are included with your Table Saw

11CRRFTSMRNTABLESAW315.228110

L,*.l.,.l,L,J.l,l.,.I,*,l.*,l,,,I.,,I,.l.,,I.i

WITH7/16in.SOCKETADJUSTABLE Wrench

Socketwrench

Combination Square

Speed and Wiring

Safety Devices

Operating Components

13CRRFTSMRNTABLESAW315.228110

Know Your Table SAW Bladeguard

Blade Adjustinghandle Bevel

Miter Fenceholder Storage Brackets Lockingclamps

Legstand

Padlock Notprovided

Off position before plugging tool into the power

Teeth

Source

Leveling feet

Assembling LEG Stand

Fiat washers 5/16 Hex nuts 5/16-18

NUT LEVELINGFOOT--HEX

Storagebracketsupper Brace Lowerbrace

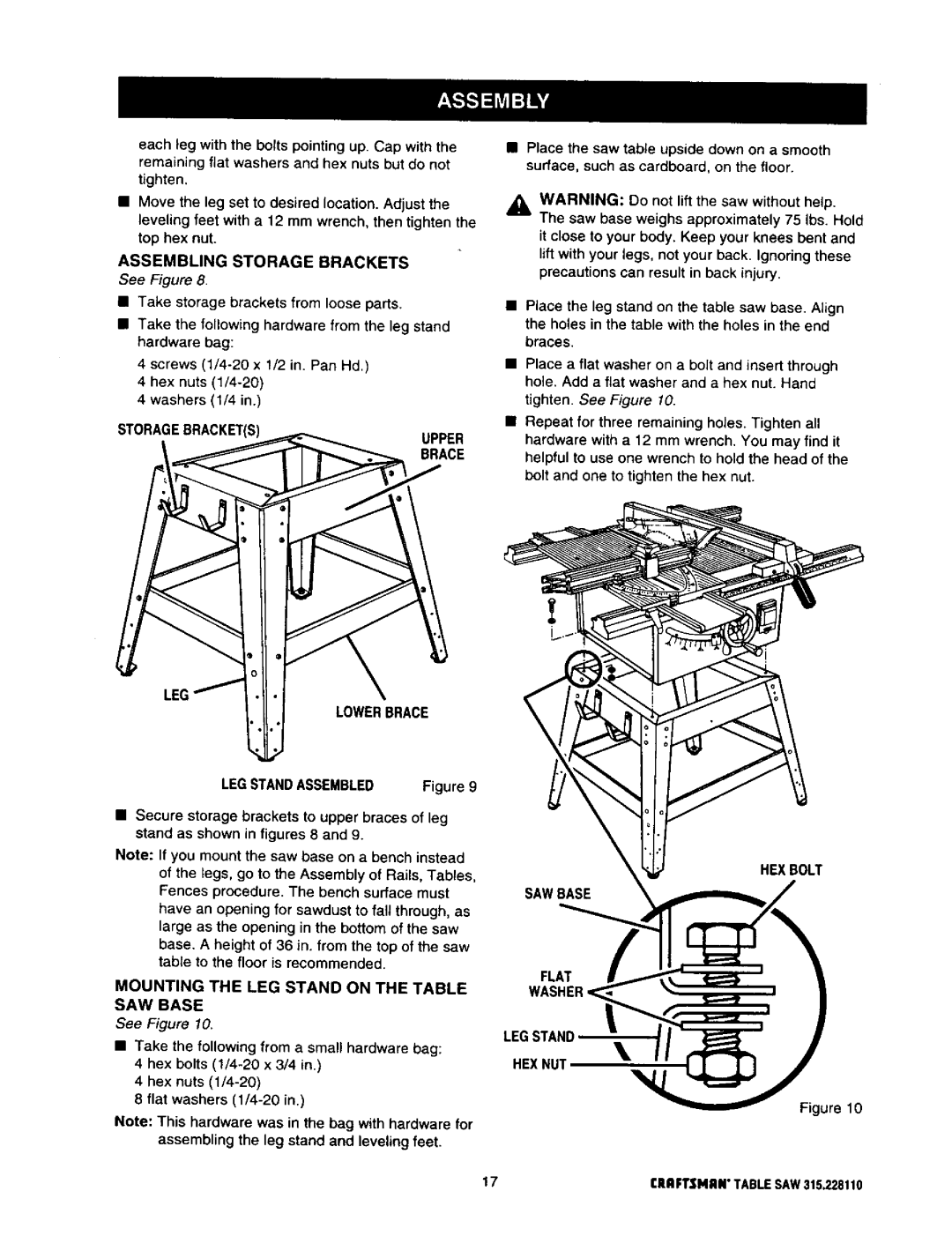

Assembling Storage Brackets

Legstandassembled Figure

Hexbolt Mounting the LEG Stand on the Table SAW Base

Endcap Frontrail Scale

To Install Miter Table and Fence

RAi

Holdernut

Lock Lever

To Install Accessory Table and RIP Fence

Hole B Tableslot Accessory

Smallhex

To Install Blade Guard

Throatplate

Hexwrench

Types of Cuts

Grounding

Groundingpin Coverofgrounded Outletbox

Motor Cord

CRRFTSI4RNTABLE SAW315.228110

CuI-rlNG Tips

Throatplatebladeguard To Remove the Blade

Bevelblade Locking Lever Adjusting Handle

Innerandouterbladewasher

Large Small HEX Wrench

Remove the Throat Plate

Loosen Nuts Riving Knife Guard Assembly

Tocenterrivingknife

Rearrangeshims Figure

To Reduce Risk of Kickback

It is weUworth using precautions to avoid the risks

To Avoid Kickback

Use these guidelines to avoid kickback

HOW to Mount a Featherboard

HOW to Make a Featherboard

To Make a Push Stick

Featherboard

To Adjust the Blade Angle

To Adjust the Blade Depth

Adjustinghandle RIP Fence

Angledblade

Miter Slidelock

To Lock Miter Table

Making Cuts

To Make a Straight Cross CUT

To Make a Straight RIP CUT

Blade Miterfence Guardassembly Adjustingclamp

Pushstick

Base

Woodeninsert RIP Fence

To Make a Bevel Cross CUT

Bevellockinglever Figure

Do not lock

31CRRFTSMBNTABLESAW315,2281t0

Slidingmiteraccessory Tableassemblytable

To Make a Large Panel CUT

Inarning Unplug the saw to avoid possible mlury

To Make NON-THROUGH Cuts

Raise the saw blade by pushing the bevel locking

Clamp Pushblock Bevellockinglever Figure

Unplug your saw

To Make Dado Cuts

All blades must be rated For at least

RPM

Indicator Lockinglever Screws Locknut

General Maintenance

Blade Adjusting Handle Bevelbevel

Bolt

Blade Socketadjustingwheel

To Adjust the Bevel Locking Lever

To Check the Alignment of the RIP Fence to the Blade

TAB Hexnut CAM Compression

To Adjust the Accessory Table

To Adjust the Front and Rear Rail Clamps

To Align the Miter Locking Clamps

Replace the rails and check the rail cSamps

37CRRFTSMRNTABLESAW315.228110

CRRFTSMRNTABLESAW315.22811038

RRIIFTSMIIN TABLESAW315.228110

To Check Miter Fence Alignment

Eight screws are visible on the miter base B

There are four slides located under the sliding

To Adjust the Miter Fence

Hex nuts on top of the miter table

Eccentric Screw UP Ofbase Slide

Merindicator Miter Fence Zero

To Adjust QUICK-STOP

Miter Fence

Degree

Threaded Hole Bevel Gear Backupbracket Washer

Locker Bracket Assembly

Blade Adjusting Handle CRRFTSHRNTABLESAW315.22811042

Tilt / Elevating Mechanism

43rlIAFTSMAW TABLESAW315.228110

Sliding miter table assembly does

Adjust the rivingknife with shims

Not move smoothly Adjusted

Blade is dull

Saw does not make accurate 90 or 45 degree cuts

Blade adjusting handle is hard to turn Saw does not start

Blade makes poor cuts

Motor labors in rip cut

96,100

Forlegstandassembly Referto Rguref

Craftsman 10 in. Table SAW Model no

Screw

48 **STD600803

73 **STD501003 75 *STDe01005

Key Part Number Description Quan

Description Quan

410 Key Part Number Description Quan

661811-001

49CRAFTSMANTABLESAW315.228110

CRAFTSMANTABLESAW315.22811050

Key Part Number Description Quan

Key Part Number

Key Part Number

Standard Hardware Item --May Be Purchased Locally

503

Figuref

Craftsman 10 in. Table SAW- Model no

KEY Part Number Description Quan

Parts List for Figure F

HomeCentralso