SUGGESTED SKIP TOOTH BLADES AND SPEEDS

MATERIAL

STEELS

Aluminum

Asbestos

Babbitt

Brake Lining

Carbon

Copper – Drawn

Duralumin

Lead

Magnesium

Paper Board

Rubber – Hard

Zinc

Plastics

Builders Board

Hardwoods

Plywoods

Softwoods

UNDER ½”

TEETH

PER

INCH

3

4

4

6

4

6

3

6

3

6

6

6

See note

6

6

6

6

FPM

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

1/2” TO 2”

TEETH

PER

INCH

3

4

3

4

3

4

3

4

3

4

4

4

4

4

4

4

4

FPM

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

2”AND UP

TEETH

PER

INCH

3

4

3

3

4

3

4

3

4

4

4

4

4

4

4

4

FPM

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

NOTE: | Some types of plastics lend themselves to more pronounced results with the regular saw blades. |

| Sheets under ¼” thickness and tubing under ¼” wall thickness are not adapted to skip tooth blades. |

|

|

WIDTH

1/8”

3/16”

1/4”

MIN. CUTTING RADIUS

1/4”

1/2”

3/4”

WIDTH

3/8”

1/2”

3/4”

MIN. CUTTING RADIUS

1”

MAINTENANCE

CHANGING THE BLADES

DISCONNECT MACHINE FROM POWER SOURCE.

DISCONNECT MACHINE FROM POWER SOURCE.

1.Open the upper and lower wheel guard doors and blade guard door.

2.Release tension on the saw blade.

3.Remove table alignment pin and table insert.

4.Take the blade off the wheel, and guide it through the slot in the table.

5.Install the new blade by reversing the procedure. Table alignment pin should be

LUBRICATION

The gear case is filled at the factory with

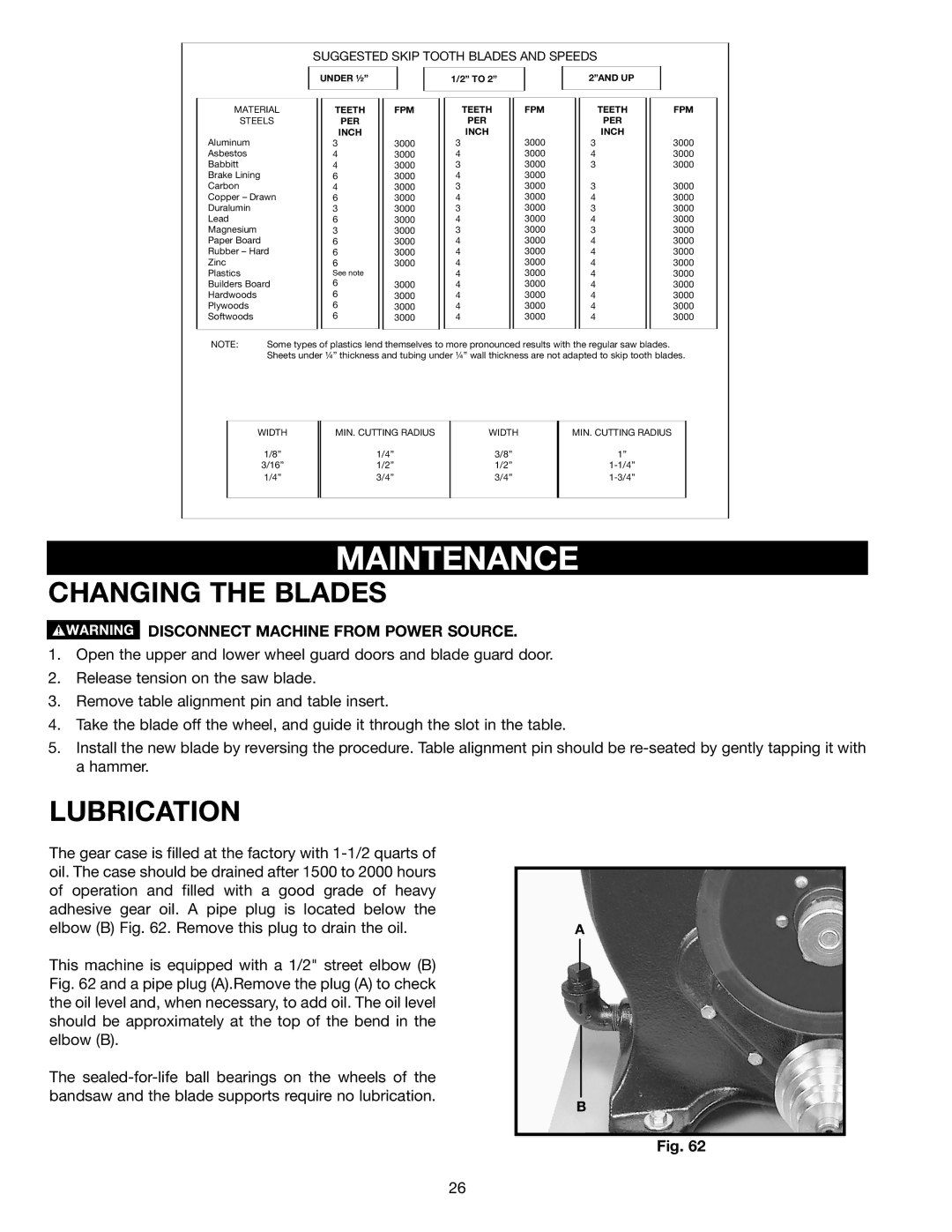

This machine is equipped with a 1/2" street elbow (B) Fig. 62 and a pipe plug (A).Remove the plug (A) to check the oil level and, when necessary, to add oil. The oil level should be approximately at the top of the bend in the elbow (B).

The

A

B

Fig. 62

26