Installation

2.5.4Installation of Piping to Units

NOTE

When using hard piping, complete all piping and evacuate the lines before connecting

NOTE

Liebert Challenger

Use caution when connecting the

1.Remove protector caps and plugs.

2.Carefully wipe coupling seats and threaded surfaces with a clean cloth.

3.Lubricate the male diaphragm and synthetic rubber seal with refrigeration grade oil.

4.Thread the coupling halves together by hand to ensure that the threads mate properly.

5.Tighten the coupling body hex nut and union nut with the proper sized wrench until the coupling bodies bottom out or until you feel a definite resistance.

6.Using a marker or pen, make a line lengthwise from the coupling union nut to the bulkhead.

7.Tighten the nuts an additional quarter turn; the misalignment of the lines shows how much the coupling has been tightened. This final quarter turn is necessary to ensure that the joint will not leak. Refer to Table 10 for torque requirements.

8.Add liquid refrigerant charge for any

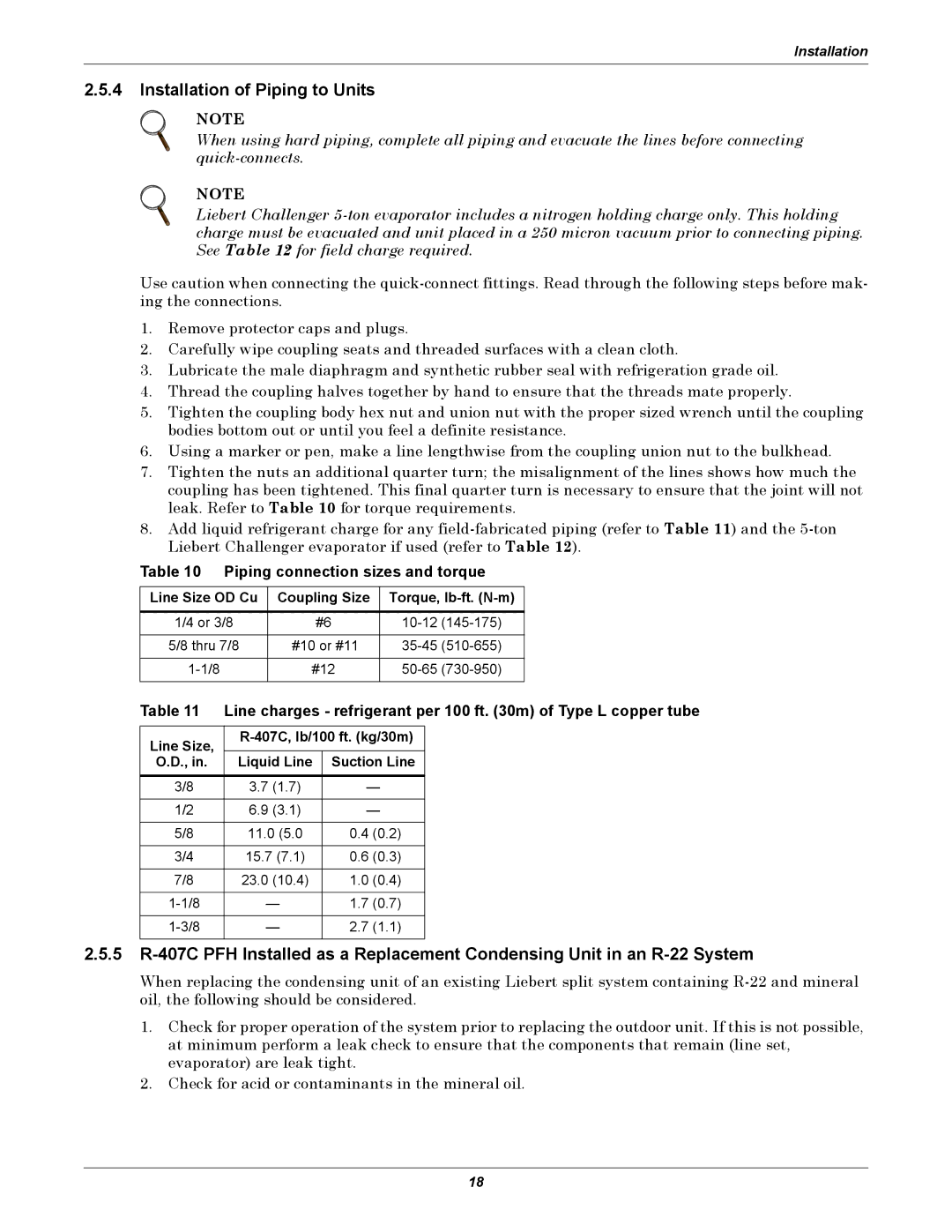

Table 10 Piping connection sizes and torque

Line Size OD Cu | Coupling Size | Torque, |

|

|

|

1/4 or 3/8 | #6 | |

|

|

|

5/8 thru 7/8 | #10 or #11 | |

|

|

|

#12 | ||

|

|

|

Table 11 Line charges - refrigerant per 100 ft. (30m) of Type L copper tube

Line Size, |

| ||

|

|

| |

O.D., in. | Liquid Line | Suction Line | |

|

|

|

|

3/8 | 3.7 | (1.7) | — |

|

|

|

|

1/2 | 6.9 | (3.1) | — |

|

|

| |

5/8 | 11.0 (5.0 | 0.4 (0.2) | |

|

|

| |

3/4 | 15.7 (7.1) | 0.6 (0.3) | |

|

|

|

|

7/8 | 23.0 | (10.4) | 1.0 (0.4) |

|

|

| |

— | 1.7 (0.7) | ||

|

|

| |

— | 2.7 (1.1) | ||

|

|

|

|

2.5.5

When replacing the condensing unit of an existing Liebert split system containing

1.Check for proper operation of the system prior to replacing the outdoor unit. If this is not possible, at minimum perform a leak check to ensure that the components that remain (line set, evaporator) are leak tight.

2.Check for acid or contaminants in the mineral oil.

18