Installation

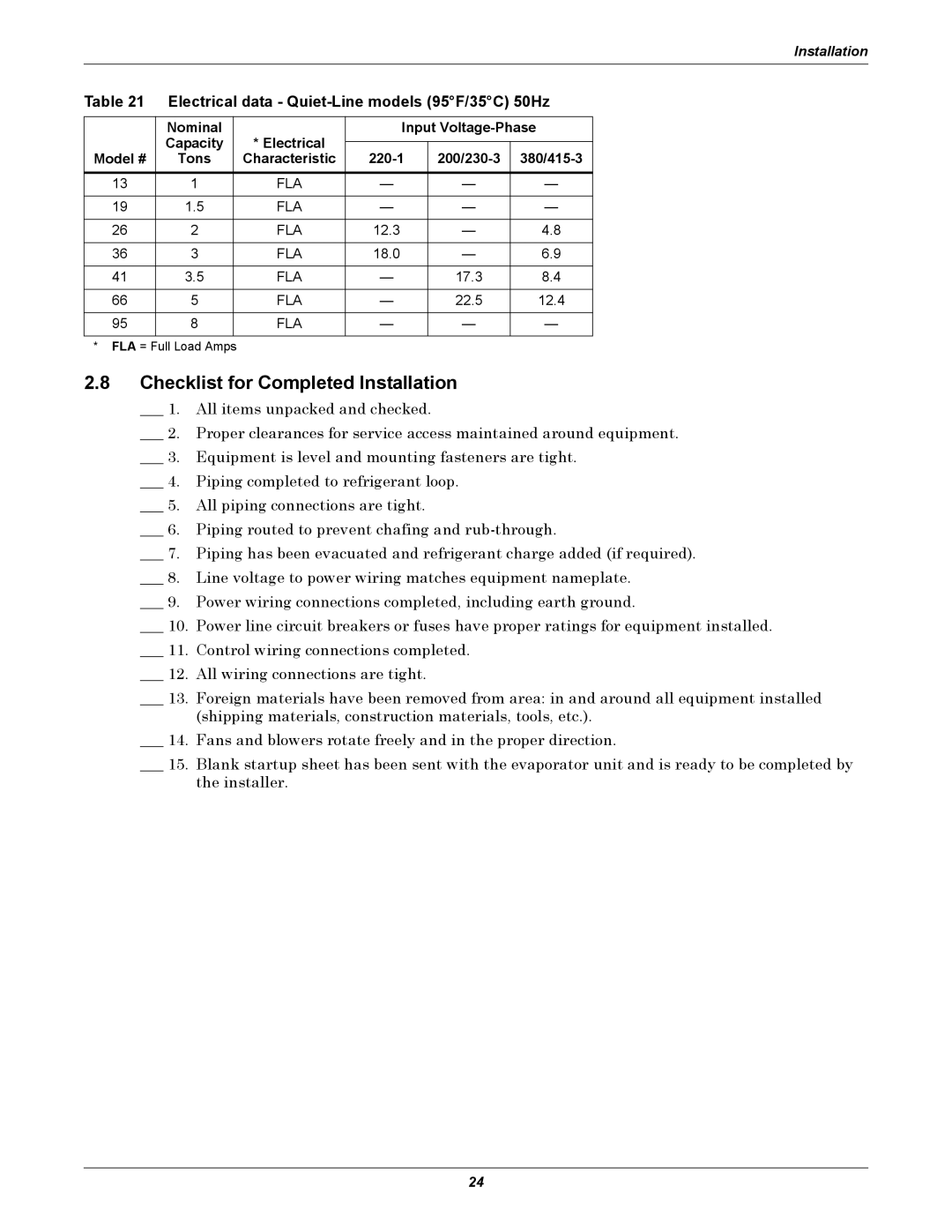

Table 21 Electrical data - Quiet-Line models (95°F/35°C) 50Hz

| Nominal |

| Input |

| ||

| Capacity | * Electrical |

|

|

|

|

|

|

|

|

| ||

Model # | Tons | Characteristic | ||||

|

|

|

|

|

|

|

13 | 1 | FLA | — | — |

| — |

|

|

|

|

|

|

|

19 | 1.5 | FLA | — | — |

| — |

|

|

|

|

|

|

|

26 | 2 | FLA | 12.3 | — |

| 4.8 |

|

|

|

|

|

|

|

36 | 3 | FLA | 18.0 | — |

| 6.9 |

|

|

|

|

|

|

|

41 | 3.5 | FLA | — | 17.3 |

| 8.4 |

|

|

|

|

|

|

|

66 | 5 | FLA | — | 22.5 |

| 12.4 |

|

|

|

|

|

|

|

95 | 8 | FLA | — | — |

| — |

|

|

|

|

|

|

|

*FLA = Full Load Amps

2.8Checklist for Completed Installation

___ 1. All items unpacked and checked.

___ 2. Proper clearances for service access maintained around equipment.

___ 3. Equipment is level and mounting fasteners are tight.

___ 4. Piping completed to refrigerant loop.

___ 5. All piping connections are tight.

___ 6. Piping routed to prevent chafing and

___ 7. Piping has been evacuated and refrigerant charge added (if required).

___ 8. Line voltage to power wiring matches equipment nameplate.

___ 9. Power wiring connections completed, including earth ground.

___ 10. Power line circuit breakers or fuses have proper ratings for equipment installed.

___ 11. Control wiring connections completed.

___ 12. All wiring connections are tight.

___ 13. Foreign materials have been removed from area: in and around all equipment installed (shipping materials, construction materials, tools, etc.).

___ 14. Fans and blowers rotate freely and in the proper direction.

___ 15. Blank startup sheet has been sent with the evaporator unit and is ready to be completed by the installer.

24