Installation

2.5.2Pre-Charged Line Sets

Liebert

NOTICE

Risk of improper handling and installation of

Care must be taken to prevent kinking the

Use tube benders and make all bends before making connections to either end of the pre- charged pipes. Coil any excess tubing in a horizontal plane with the slope of the tubing toward the condensing unit. Use a soft, flexible material to pack around the tubes when sealing openings in walls to prevent tube damage and to reduce vibration transmission.

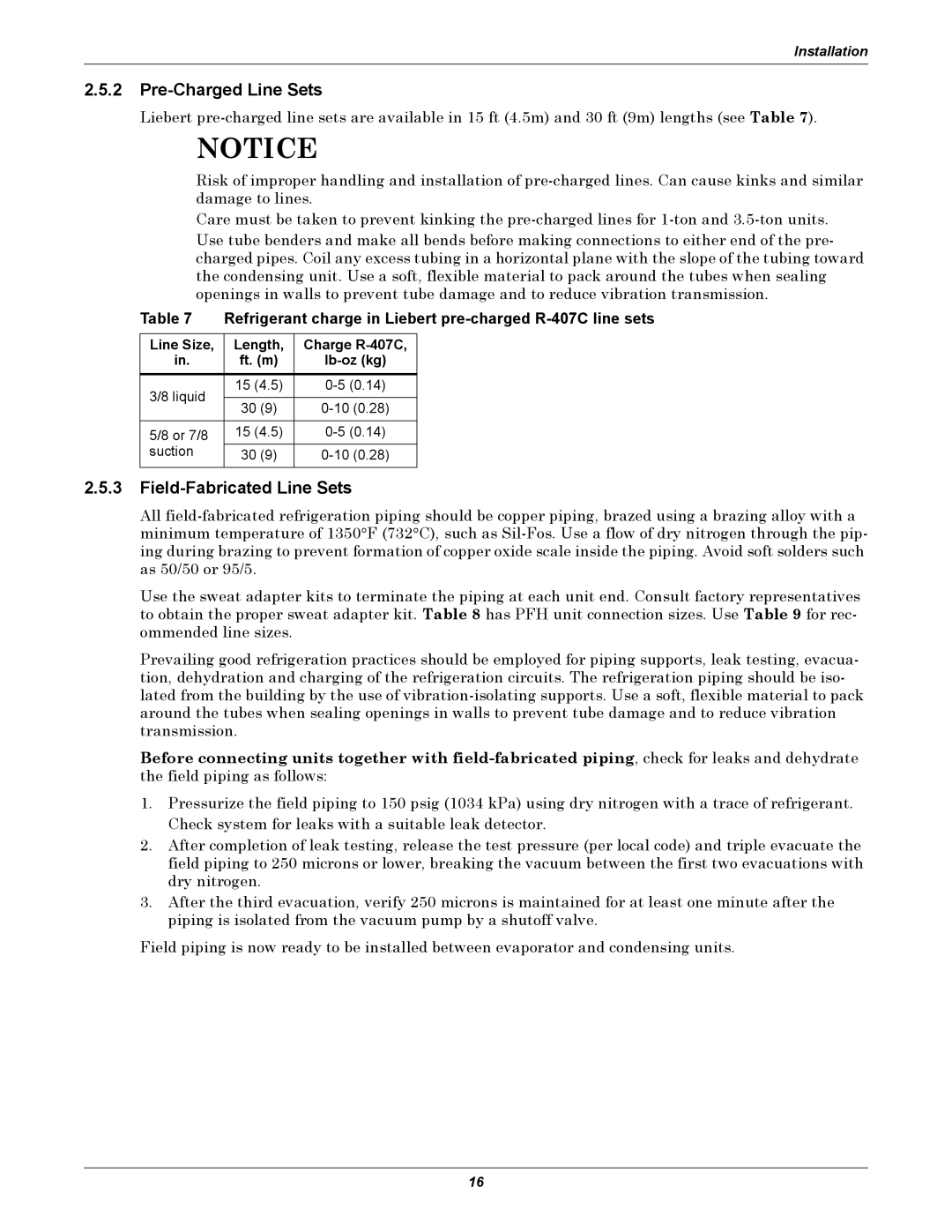

Table 7 | Refrigerant charge in Liebert | ||

|

|

|

|

Line Size, | Length, | Charge |

|

in. | ft. (m) |

|

|

3/8 liquid | 15 (4.5) |

| |

|

|

| |

30 (9) |

| ||

|

| ||

|

|

|

|

5/8 or 7/8 | 15 (4.5) |

| |

suction | 30 (9) |

| |

|

|

|

|

2.5.3Field-Fabricated Line Sets

All

Use the sweat adapter kits to terminate the piping at each unit end. Consult factory representatives to obtain the proper sweat adapter kit. Table 8 has PFH unit connection sizes. Use Table 9 for rec- ommended line sizes.

Prevailing good refrigeration practices should be employed for piping supports, leak testing, evacua- tion, dehydration and charging of the refrigeration circuits. The refrigeration piping should be iso- lated from the building by the use of

Before connecting units together with

1.Pressurize the field piping to 150 psig (1034 kPa) using dry nitrogen with a trace of refrigerant. Check system for leaks with a suitable leak detector.

2.After completion of leak testing, release the test pressure (per local code) and triple evacuate the field piping to 250 microns or lower, breaking the vacuum between the first two evacuations with dry nitrogen.

3.After the third evacuation, verify 250 microns is maintained for at least one minute after the piping is isolated from the vacuum pump by a shutoff valve.

Field piping is now ready to be installed between evaporator and condensing units.

16