INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

FOR “WSD”” SLEEVE

MOUNTING HARDWARE PROVIDED

ITEM | DESCRIPTION | QTY. | |

NO. | |||

|

| ||

1 | SCREW, #12A X 2” | 5 | |

|

|

|

WALL PREPARATION:

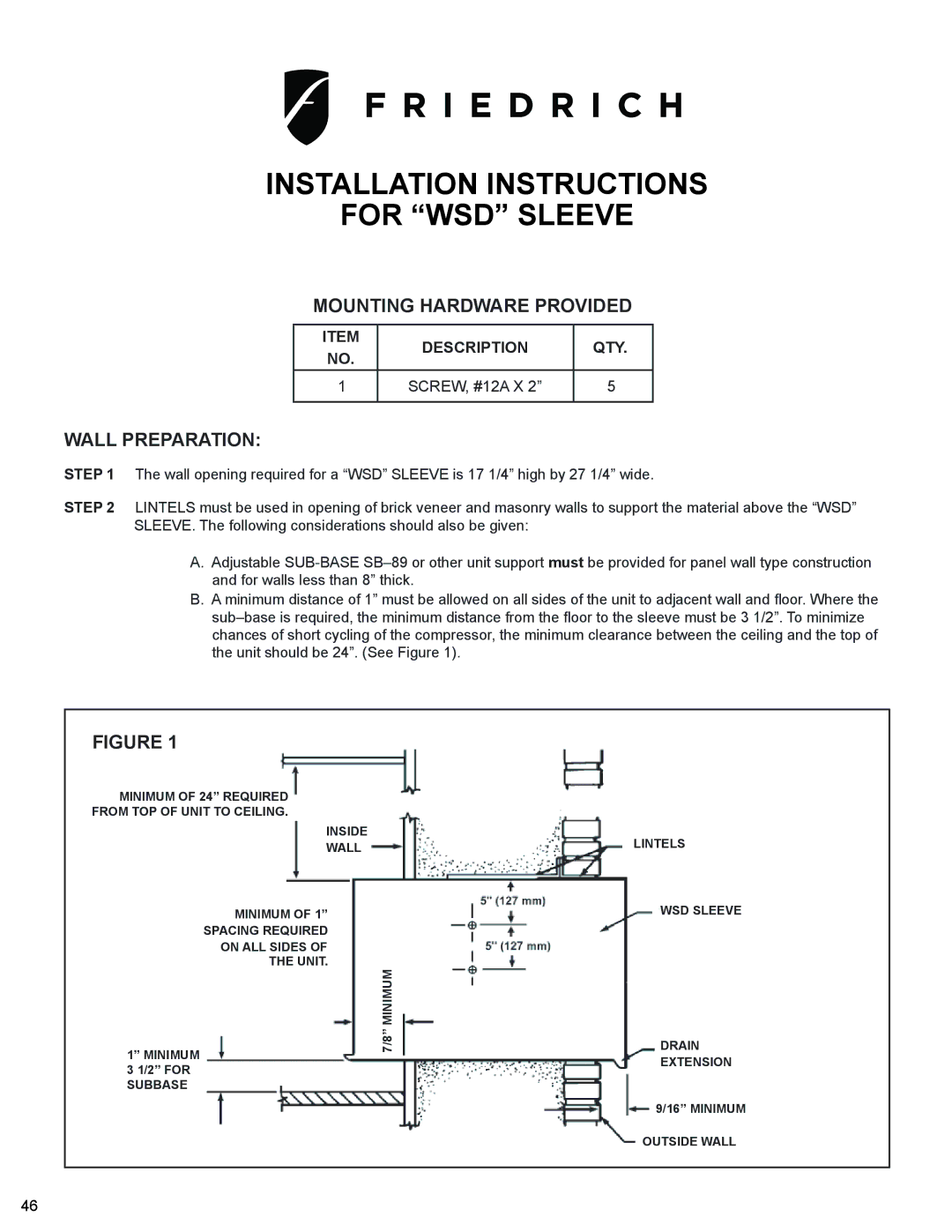

STEP 1 The wall opening required for a “WSD” SLEEVE is 17 1/4” high by 27 1/4” wide.

STEP 2 LINTELS must be used in opening of brick veneer and masonry walls to support the material above the “WSD” SLEEVE. The following considerations should also be given:

A.Adjustable

B.A minimum distance of 1” must be allowed on all sides of the unit to adjacent wall and floor. Where the

FIGURE 1

MINIMUM OF 24” REQUIRED FROM TOP OF UNIT TO CEILING.

INSIDE

WALL

MINIMUM OF 1”

SPACING REQUIRED

ON ALL SIDES OF

THE UNIT.

1” MINIMUM 3 1/2” FOR SUBBASE

7/8” MINIMUM

LINTELS

WSD SLEEVE

DRAIN

EXTENSION

9/16” MINIMUM

OUTSIDE WALL

46