TERMINATION LOCATIONS

NOTES: Refer to Location Requirements and Considerations for combustion air contaminant restrictions.

The following bullets and diagram describe the restrictions concern- ing the appropriate location of vent/flue pipe and combustion air intake pipe (when applicable) terminations. Refer to

•All terminations (flue and/or intake) must be located at least 12 inches above ground level or the anticipated snow level.

•Vent terminations

NOTE: This provision does not apply to the combustion air intake termination of a direct vent application.

•The vent termination of a

•The vent termination of a direct vent application must terminate at least 12 inches from any opening through which flue gases may enter a building (door, window, or gravity air inlet).

•The vent termination of vent pipe run vertically through a roof must terminate at least 12 inches above the roof line (or the anticipated snow level) and be at least 12 inches from any vertical wall (including any anticipated snow build up).

•A vent termination shall not terminate over public walkways or over an area where condensate or vapor could create a nuisance or hazard or could be detrimental to the operation of regulators, relief valves, or other equipment.

•The combustion air intake termination of a direct vent application should not terminate in an area which is frequently dusty or dirty.

NOTE: In Canada, the Canadian Fuel Gas Code takes precedence over the preceding termination restrictions.

CANADIAN VENTING REQUIREMENTS

In Canada, venting must conform to the requirements of the cur- rent

The vent can be run through an existing unused chimney provided the space between the vent pipe and the chimney is insulated and closed with a

STANDARD FURNACE CONNECTIONS

It is the responsibility of the installer to ensure that the piping con- nections to the furnace are secure, airtight, and adequately sup- ported.

As shipped, attachment “couplings” for vent/flue and combustion air intake pipe connections are provided on the furnace’s top cover (upflow) or basepan (counterflow). To use the standard connec- tions, field supplied vent/flue pipe and combustion air intake pipe (when applicable) should be secured directly to the furnace at these locations.

VENT/FLUE PIPE

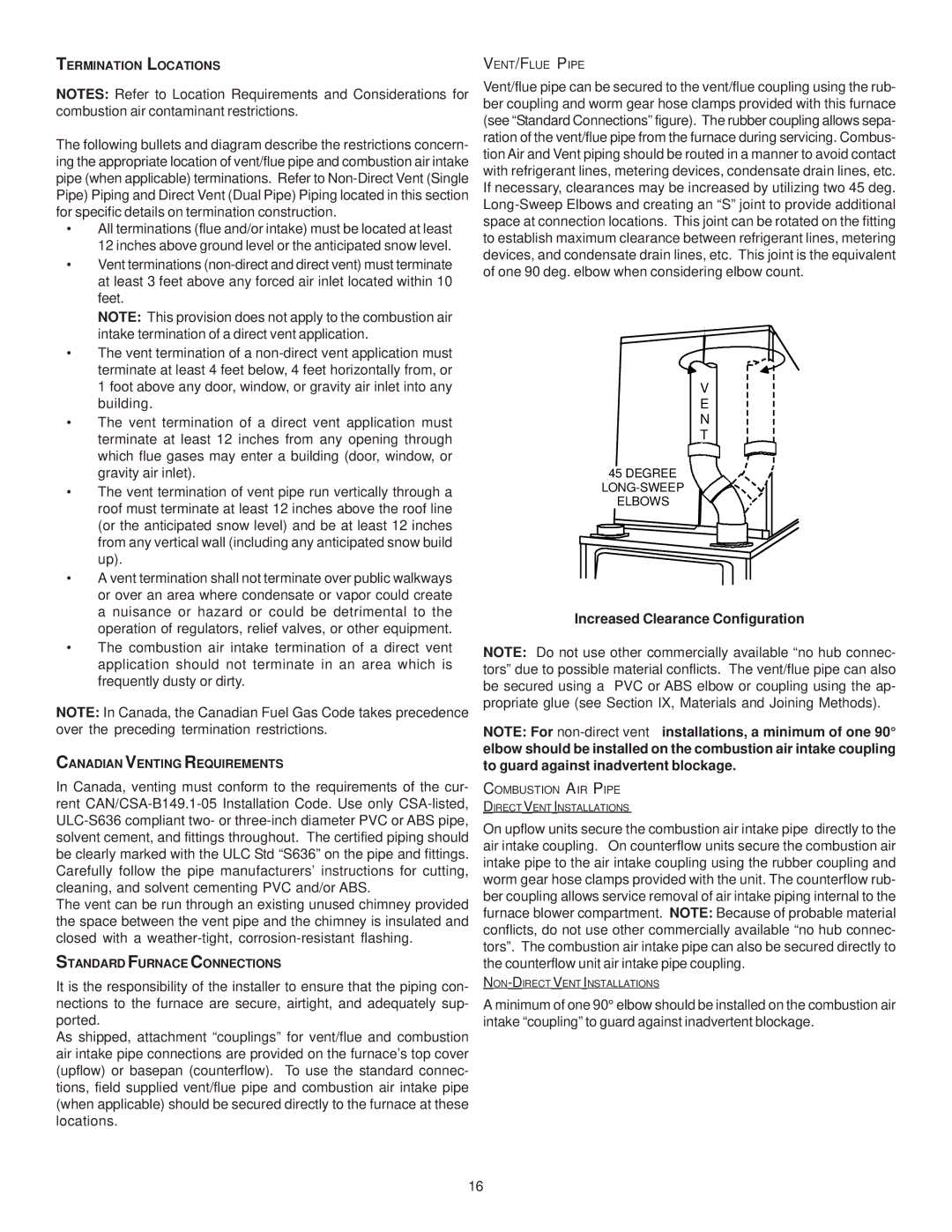

Vent/flue pipe can be secured to the vent/flue coupling using the rub- ber coupling and worm gear hose clamps provided with this furnace (see “Standard Connections” figure). The rubber coupling allows sepa- ration of the vent/flue pipe from the furnace during servicing. Combus- tion Air and Vent piping should be routed in a manner to avoid contact with refrigerant lines, metering devices, condensate drain lines, etc. If necessary, clearances may be increased by utilizing two 45 deg.

V

E

N

T

45 DEGREE

ELBOWS

Increased Clearance Configuration

NOTE: Do not use other commercially available “no hub connec- tors” due to possible material conflicts. The vent/flue pipe can also be secured using a PVC or ABS elbow or coupling using the ap- propriate glue (see Section IX, Materials and Joining Methods).

NOTE: For

COMBUSTION AIR PIPE

DIRECT VENT INSTALLATIONS

On upflow units secure the combustion air intake pipe directly to the air intake coupling. On counterflow units secure the combustion air intake pipe to the air intake coupling using the rubber coupling and worm gear hose clamps provided with the unit. The counterflow rub- ber coupling allows service removal of air intake piping internal to the furnace blower compartment. NOTE: Because of probable material conflicts, do not use other commercially available “no hub connec- tors”. The combustion air intake pipe can also be secured directly to the counterflow unit air intake pipe coupling.

A minimum of one 90° elbow should be installed on the combustion air intake “coupling” to guard against inadvertent blockage.

16