Natural Gas Capacity of Pipe

In Cubic Feet of Gas Per Hour (CFH)

Length of |

| Nominal Black Pipe Size |

| ||

Pipe in Feet | 1/2" | 3/4" | 1" | 1 1/4" | 1 1/2" |

10 | 132 | 278 | 520 | 1050 | 1600 |

20 | 92 | 190 | 350 | 730 | 1100 |

30 | 73 | 152 | 285 | 590 | 980 |

40 | 63 | 130 | 245 | 500 | 760 |

50 | 56 | 115 | 215 | 440 | 670 |

60 | 50 | 105 | 195 | 400 | 610 |

70 | 46 | 96 | 180 | 370 | 560 |

80 | 43 | 90 | 170 | 350 | 530 |

90 | 40 | 84 | 160 | 320 | 490 |

100 | 38 | 79 | 150 | 305 | 460 |

(Pressure 0.5 psig or less and pressure drop of 0.3" W.C.; Based on

rigid pipe must be used to reach the outside of the cabinet. A

•Use listed gas appliance connectors in accordance with their instructions. Connectors must be fully in the same room as the furnace.

•Protect connectors and

0.60 Specific Gravity Gas)

CFH = BTUH Furnace Input

Heating Value of Gas (BTU/Cubic Foot)

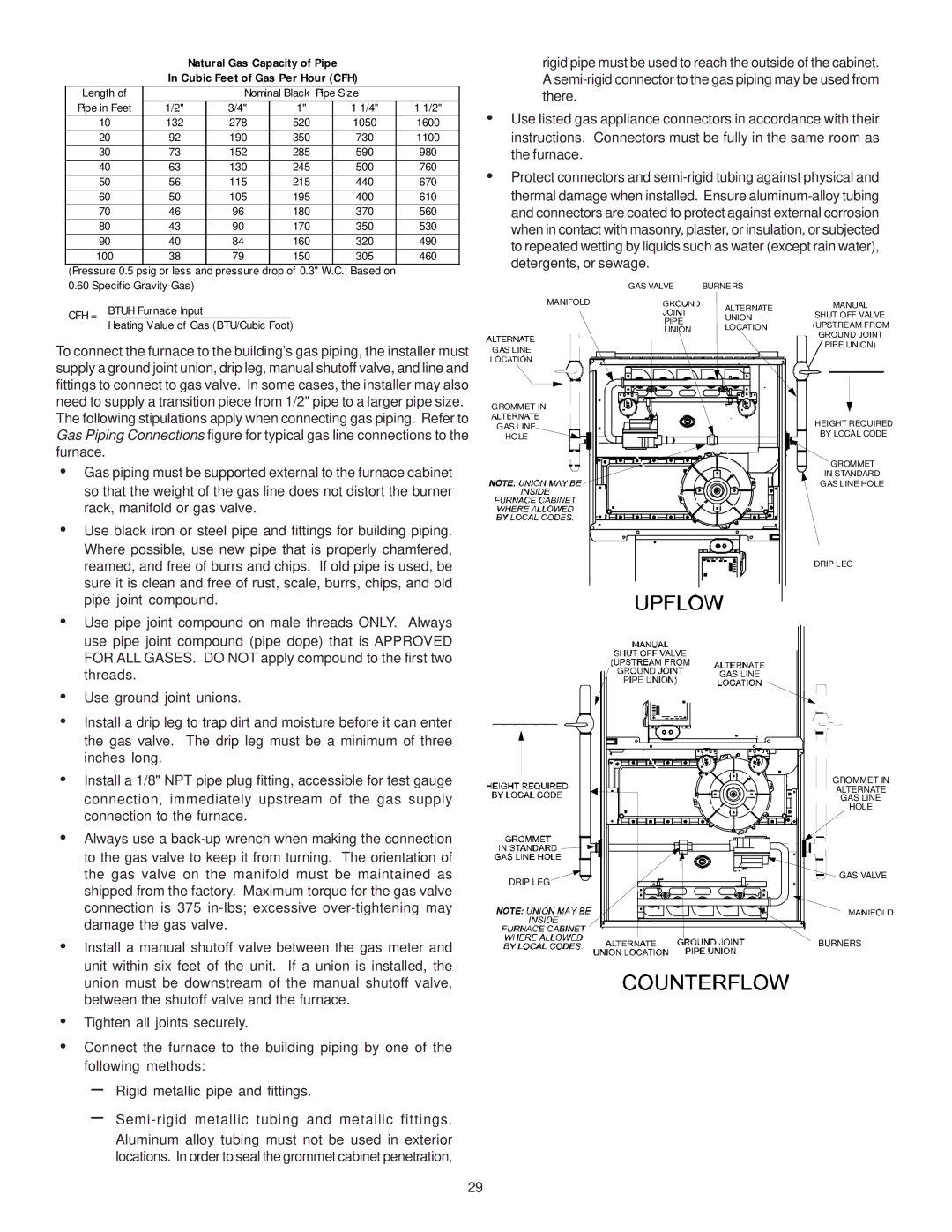

To connect the furnace to the building’s gas piping, the installer must supply a ground joint union, drip leg, manual shutoff valve, and line and fittings to connect to gas valve. In some cases, the installer may also need to supply a transition piece from 1/2" pipe to a larger pipe size. The following stipulations apply when connecting gas piping. Refer to Gas Piping Connections figure for typical gas line connections to the furnace.

• Gas piping must be supported external to the furnace cabinet |

so that the weight of the gas line does not distort the burner |

rack, manifold or gas valve. |

• Use black iron or steel pipe and fittings for building piping. |

Where possible, use new pipe that is properly chamfered, |

reamed, and free of burrs and chips. If old pipe is used, be |

sure it is clean and free of rust, scale, burrs, chips, and old |

pipe joint compound. |

• Use pipe joint compound on male threads ONLY. Always |

use pipe joint compound (pipe dope) that is APPROVED |

FOR ALL GASES. DO NOT apply compound to the first two |

GAS VALVE | BURNERS | |

MANIFOLD | ALTERNATE | |

| ||

PIPE | UNION | |

LOCATION | ||

UNION | ||

GAS LINE |

| |

GROMMET IN |

| |

GAS LINE |

| |

HOLE |

|

MANUAL

SHUT OFF VALVE (UPSTREAM FROM

PIPE UNION)

HEIGHT REQUIRED

BY LOCAL CODE

GROMMET

IN STANDARD

GAS LINE HOLE

DRIP LEG

threads. |

• Use ground joint unions. |

• Install a drip leg to trap dirt and moisture before it can enter |

the gas valve. The drip leg must be a minimum of three |

inches long. |

• Install a 1/8" NPT pipe plug fitting, accessible for test gauge |

connection, immediately upstream of the gas supply |

connection to the furnace. |

• Always use a |

to the gas valve to keep it from turning. The orientation of |

the gas valve on the manifold must be maintained as |

shipped from the factory. Maximum torque for the gas valve |

connection is 375 |

damage the gas valve. |

• Install a manual shutoff valve between the gas meter and |

unit within six feet of the unit. If a union is installed, the |

union must be downstream of the manual shutoff valve, |

between the shutoff valve and the furnace. |

• Tighten all joints securely. |

• Connect the furnace to the building piping by one of the |

following methods: |

– Rigid metallic pipe and fittings. |

– |

Aluminum alloy tubing must not be used in exterior |

locations. In order to seal the grommet cabinet penetration, |

| GROMMET IN |

| ALTERNATE |

| GAS LINE |

| HOLE |

DRIP LEG | GAS VALVE |

| |

| BURNERS |

29