90°

ELBOWS

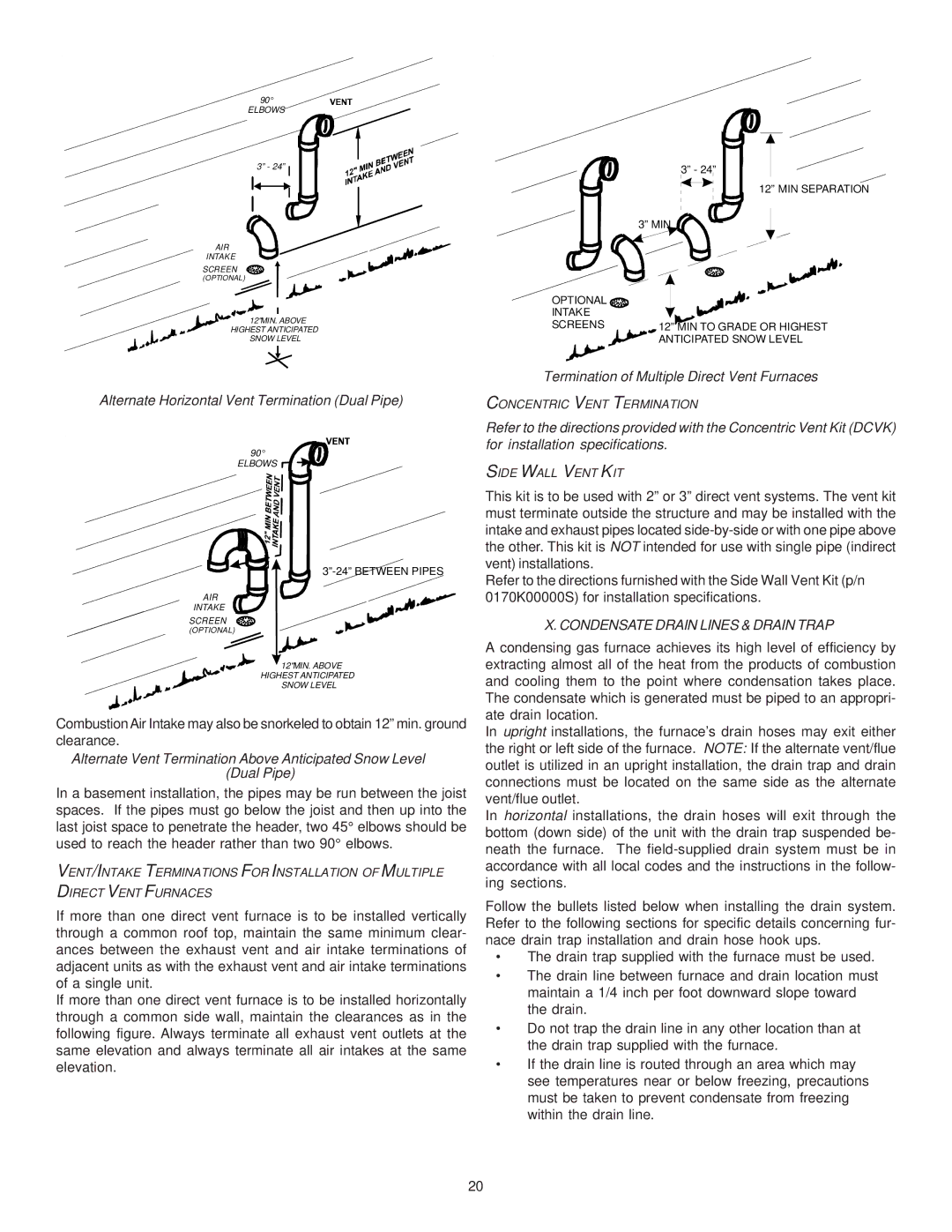

3” - 24”

AIR

INTAKE

SCREEN

(OPTIONAL)

12" MIN. ABOVE HIGHEST ANTICIPATED

SNOW LEVEL

| 3” - 24” |

| 12” MIN SEPARATION |

| 3” MIN |

OPTIONAL |

|

INTAKE |

|

SCREENS | 12” MIN TO GRADE OR HIGHEST |

| ANTICIPATED SNOW LEVEL |

Alternate Horizontal Vent Termination (Dual Pipe)

90°

ELBOWS

Termination of Multiple Direct Vent Furnaces

CONCENTRIC VENT TERMINATION

Refer to the directions provided with the Concentric Vent Kit (DCVK) for installation specifications.

SIDE WALL VENT KIT

AIR

INTAKE

This kit is to be used with 2” or 3” direct vent systems. The vent kit must terminate outside the structure and may be installed with the intake and exhaust pipes located

Refer to the directions furnished with the Side Wall Vent Kit (p/n 0170K00000S) for installation specifications.

SCREEN

(OPTIONAL)

12" MIN. ABOVE

HIGHEST ANTICIPATED

SNOW LEVEL

Combustion Air Intake may also be snorkeled to obtain 12” min. ground clearance.

Alternate Vent Termination Above Anticipated Snow Level

(Dual Pipe)

In a basement installation, the pipes may be run between the joist spaces. If the pipes must go below the joist and then up into the last joist space to penetrate the header, two 45° elbows should be used to reach the header rather than two 90° elbows.

VENT/INTAKE TERMINATIONS FOR INSTALLATION OF MULTIPLE DIRECT VENT FURNACES

If more than one direct vent furnace is to be installed vertically through a common roof top, maintain the same minimum clear- ances between the exhaust vent and air intake terminations of adjacent units as with the exhaust vent and air intake terminations of a single unit.

If more than one direct vent furnace is to be installed horizontally through a common side wall, maintain the clearances as in the following figure. Always terminate all exhaust vent outlets at the same elevation and always terminate all air intakes at the same elevation.

20

X. CONDENSATE DRAIN LINES & DRAIN TRAP

A condensing gas furnace achieves its high level of efficiency by extracting almost all of the heat from the products of combustion and cooling them to the point where condensation takes place. The condensate which is generated must be piped to an appropri- ate drain location.

In upright installations, the furnace’s drain hoses may exit either the right or left side of the furnace. NOTE: If the alternate vent/flue outlet is utilized in an upright installation, the drain trap and drain connections must be located on the same side as the alternate vent/flue outlet.

In horizontal installations, the drain hoses will exit through the bottom (down side) of the unit with the drain trap suspended be- neath the furnace. The

Follow the bullets listed below when installing the drain system. Refer to the following sections for specific details concerning fur- nace drain trap installation and drain hose hook ups.

•The drain trap supplied with the furnace must be used.

•The drain line between furnace and drain location must maintain a 1/4 inch per foot downward slope toward the drain.

•Do not trap the drain line in any other location than at the drain trap supplied with the furnace.

•If the drain line is routed through an area which may see temperatures near or below freezing, precautions must be taken to prevent condensate from freezing within the drain line.