Troubleshooting

Problem |

| Cause | Solution |

|

|

|

|

|

|

|

|

Sprayer sprays with poor results |

| Tip is partially clogged | See Unclogging Tip/Guard Assembly, |

|

|

| page 15. |

|

|

|

|

|

| Tip is not in correct position | Rotate tip to SPRAY position. |

|

|

|

|

|

| Incorrect tip for application of | See Reversible Tip Selection Chart, |

|

| material. | page 13. |

|

|

|

|

|

| Tip filter is partially clogged or damaged. | Clean or replace filter. See page 15. |

|

|

|

|

|

| Suction Tube screen is partially clogged. | Clean or replace Suction Tube. See page |

|

|

| 16. |

|

|

|

|

|

| Tip is worn or damaged | Replace tip. See Install Tip/Guard |

|

|

| Assembly, page 14. |

|

|

|

|

|

| Material being sprayed is aerated | Do NOT shake material. Stir the material |

|

| because it was shaken. | or check the manufacturer’s recommen- |

|

|

| dation for the material being sprayed. |

|

|

|

|

|

| Pressure control is too low or Hi/Lo switch | Turn up pressure control or shift Hi/Lo |

|

| is in Lo range | switch to hi range. |

|

|

|

|

|

| Material being sprayed is too cold to | Warm material. |

|

| spray. |

|

|

|

|

|

|

| Inlet or outlet valves are worn. | See Outlet Valve Repair, page 25 and |

|

|

| Inlet Valve Removal/Service, page 24. |

|

|

| |

Paint leaks from sprayer trigger area. | Sprayer has reached its maximum life. | Replace sprayer. | |

|

|

| |

Battery is discharged but charger still dis- | Damaged battery. | Replace battery. | |

plays green light when battery is inserted. |

|

| |

|

|

|

|

Battery does not last long. |

| Battery life varies with material, tip size, | See Charging the Battery, page 8. |

|

| pressure, and speed setting. |

|

|

|

| |

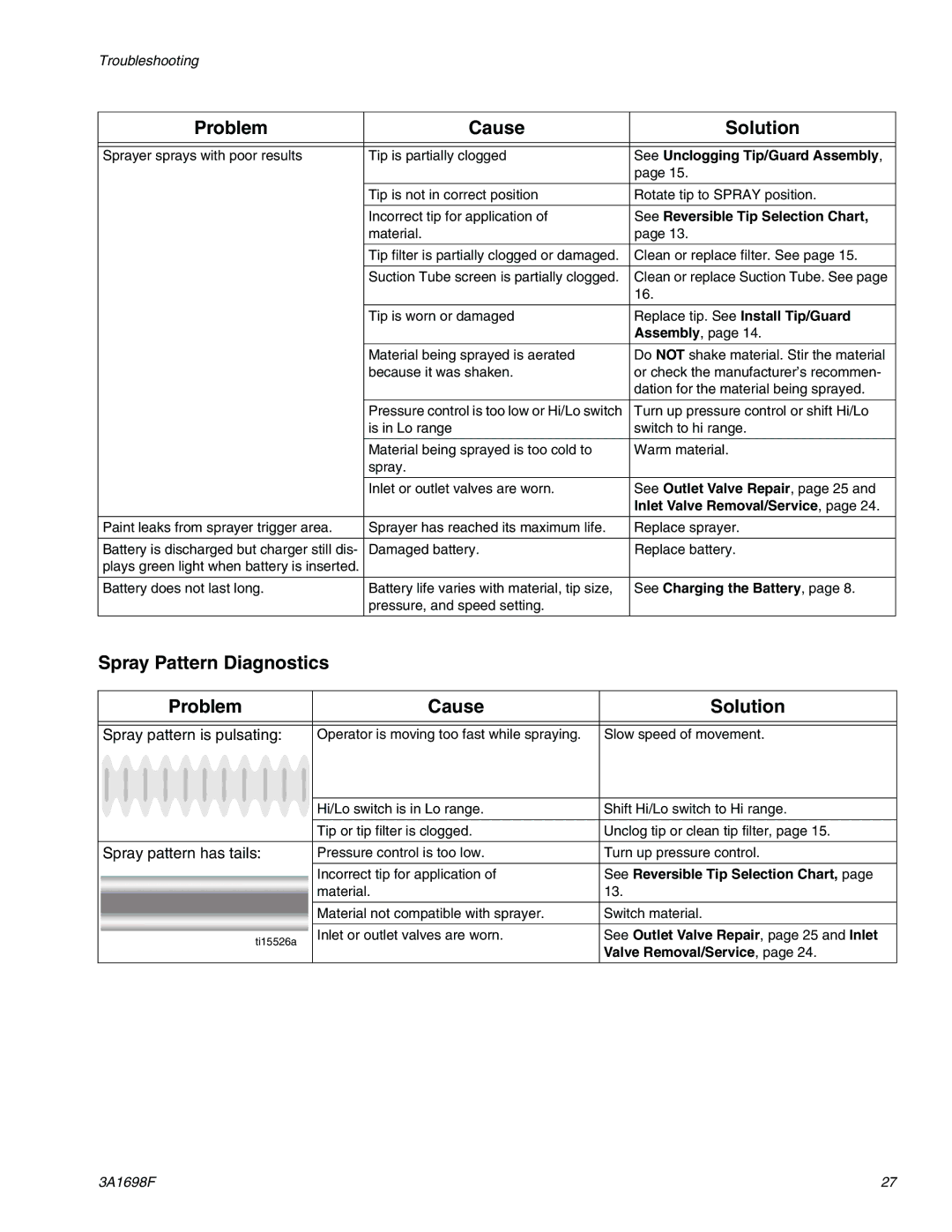

Spray Pattern Diagnostics |

|

| |

|

|

|

|

Problem |

| Cause | Solution |

|

| ||

|

| ||

Spray pattern is pulsating: | Operator is moving too fast while spraying. Slow speed of movement. | ||

| Hi/Lo switch is in Lo range. | Shift Hi/Lo switch to Hi range. |

| Tip or tip filter is clogged. | Unclog tip or clean tip filter, page 15. |

|

|

|

Spray pattern has tails: | Pressure control is too low. | Turn up pressure control. |

| Incorrect tip for application of | See Reversible Tip Selection Chart, page |

| material. | 13. |

|

|

|

| Material not compatible with sprayer. | Switch material. |

|

|

|

ti15526a | Inlet or outlet valves are worn. | See Outlet Valve Repair, page 25 and Inlet |

| Valve Removal/Service, page 24. | |

|

|

3A1698F | 27 |