Empty and Flush Entire System (new system or end of job)

Empty and Flush Entire System (new system or end of job)

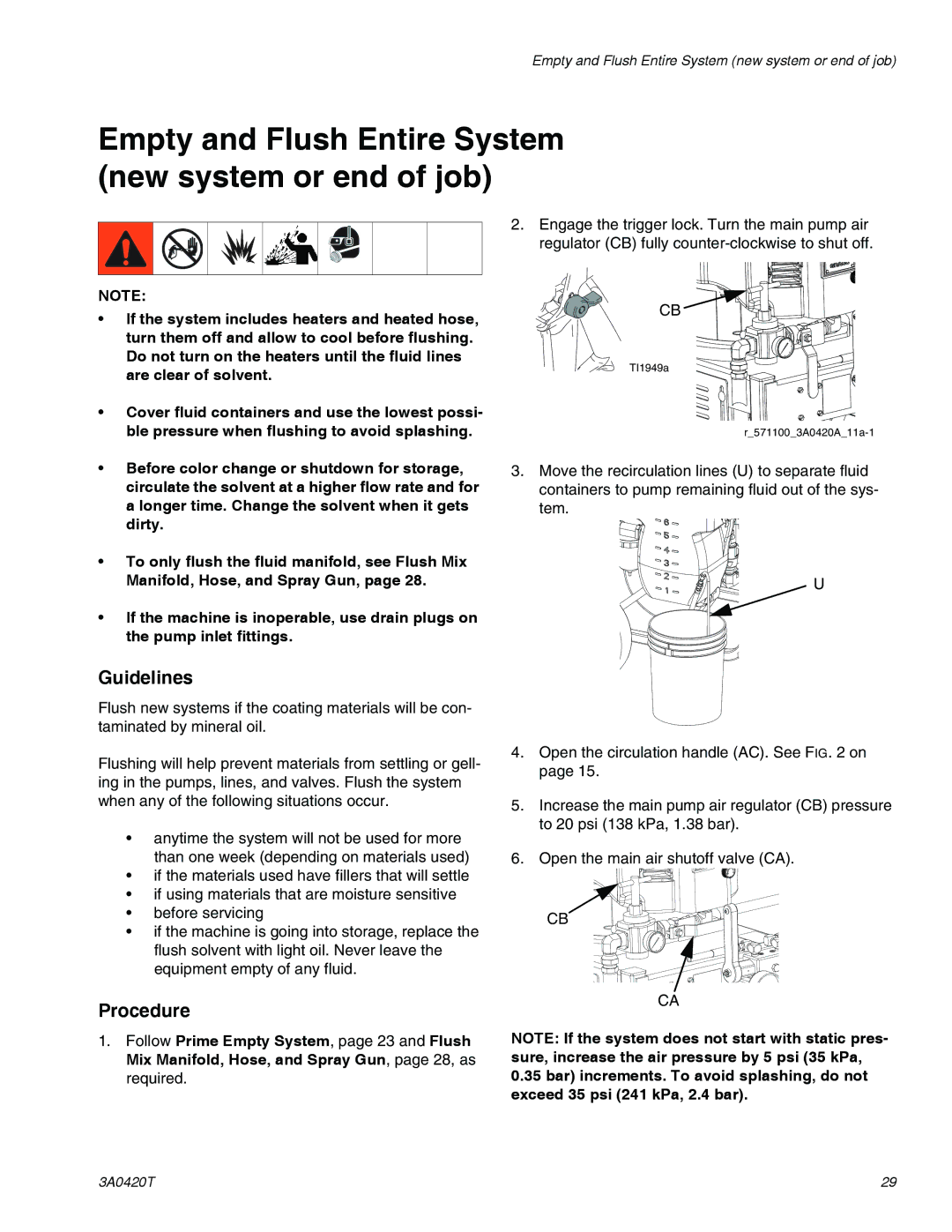

2. Engage the trigger lock. Turn the main pump air regulator (CB) fully

NOTE:

•If the system includes heaters and heated hose, turn them off and allow to cool before flushing. Do not turn on the heaters until the fluid lines are clear of solvent.

•Cover fluid containers and use the lowest possi- ble pressure when flushing to avoid splashing.

•Before color change or shutdown for storage, circulate the solvent at a higher flow rate and for a longer time. Change the solvent when it gets dirty.

•To only flush the fluid manifold, see Flush Mix Manifold, Hose, and Spray Gun, page 28.

•If the machine is inoperable, use drain plugs on the pump inlet fittings.

Guidelines

Flush new systems if the coating materials will be con- taminated by mineral oil.

Flushing will help prevent materials from settling or gell- ing in the pumps, lines, and valves. Flush the system when any of the following situations occur.

•anytime the system will not be used for more than one week (depending on materials used)

•if the materials used have fillers that will settle

•if using materials that are moisture sensitive

•before servicing

•if the machine is going into storage, replace the flush solvent with light oil. Never leave the equipment empty of any fluid.

Procedure

1.Follow Prime Empty System, page 23 and Flush Mix Manifold, Hose, and Spray Gun, page 28, as required.

CB

TI1949a

3.Move the recirculation lines (U) to separate fluid containers to pump remaining fluid out of the sys- tem.

U

4.Open the circulation handle (AC). See FIG. 2 on page 15.

5.Increase the main pump air regulator (CB) pressure to 20 psi (138 kPa, 1.38 bar).

6.Open the main air shutoff valve (CA).

CB

CA

NOTE: If the system does not start with static pres- sure, increase the air pressure by 5 psi (35 kPa,

0.35bar) increments. To avoid splashing, do not exceed 35 psi (241 kPa, 2.4 bar).

3A0420T | 29 |