Shutdown

7.Run the pumps until the A and B hoppers (J) are empty. Salvage the material in separate, clean con- tainers.

8.Close the main air shutoff valve (CA).

CA

9.Wipe the hoppers (J) clean, then add solvent to each. Move the circulation lines (U) to waste con- tainers and push out the dirty fluids.

10.Move the recirculation lines (U) back to the hoppers. Continue recirculating until the system is thoroughly flushed.

U

J

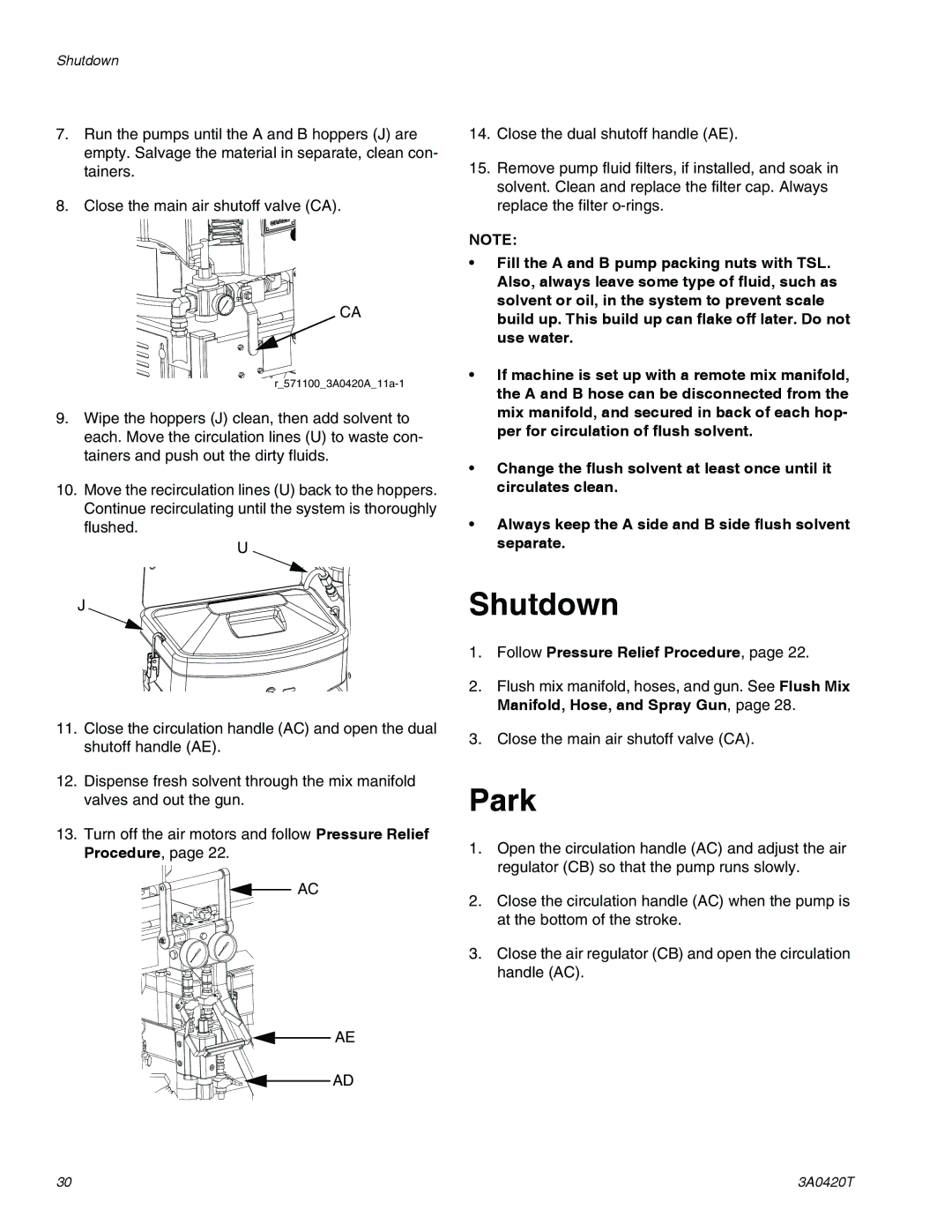

11.Close the circulation handle (AC) and open the dual shutoff handle (AE).

12.Dispense fresh solvent through the mix manifold valves and out the gun.

13.Turn off the air motors and follow Pressure Relief Procedure, page 22.

AC

AE

AD

14.Close the dual shutoff handle (AE).

15.Remove pump fluid filters, if installed, and soak in solvent. Clean and replace the filter cap. Always replace the filter

NOTE:

•Fill the A and B pump packing nuts with TSL. Also, always leave some type of fluid, such as solvent or oil, in the system to prevent scale build up. This build up can flake off later. Do not use water.

•If machine is set up with a remote mix manifold, the A and B hose can be disconnected from the mix manifold, and secured in back of each hop- per for circulation of flush solvent.

•Change the flush solvent at least once until it circulates clean.

•Always keep the A side and B side flush solvent separate.

Shutdown

1.Follow Pressure Relief Procedure, page 22.

2.Flush mix manifold, hoses, and gun. See Flush Mix Manifold, Hose, and Spray Gun, page 28.

3.Close the main air shutoff valve (CA).

Park

1.Open the circulation handle (AC) and adjust the air regulator (CB) so that the pump runs slowly.

2.Close the circulation handle (AC) when the pump is at the bottom of the stroke.

3.Close the air regulator (CB) and open the circulation handle (AC).

30 | 3A0420T |