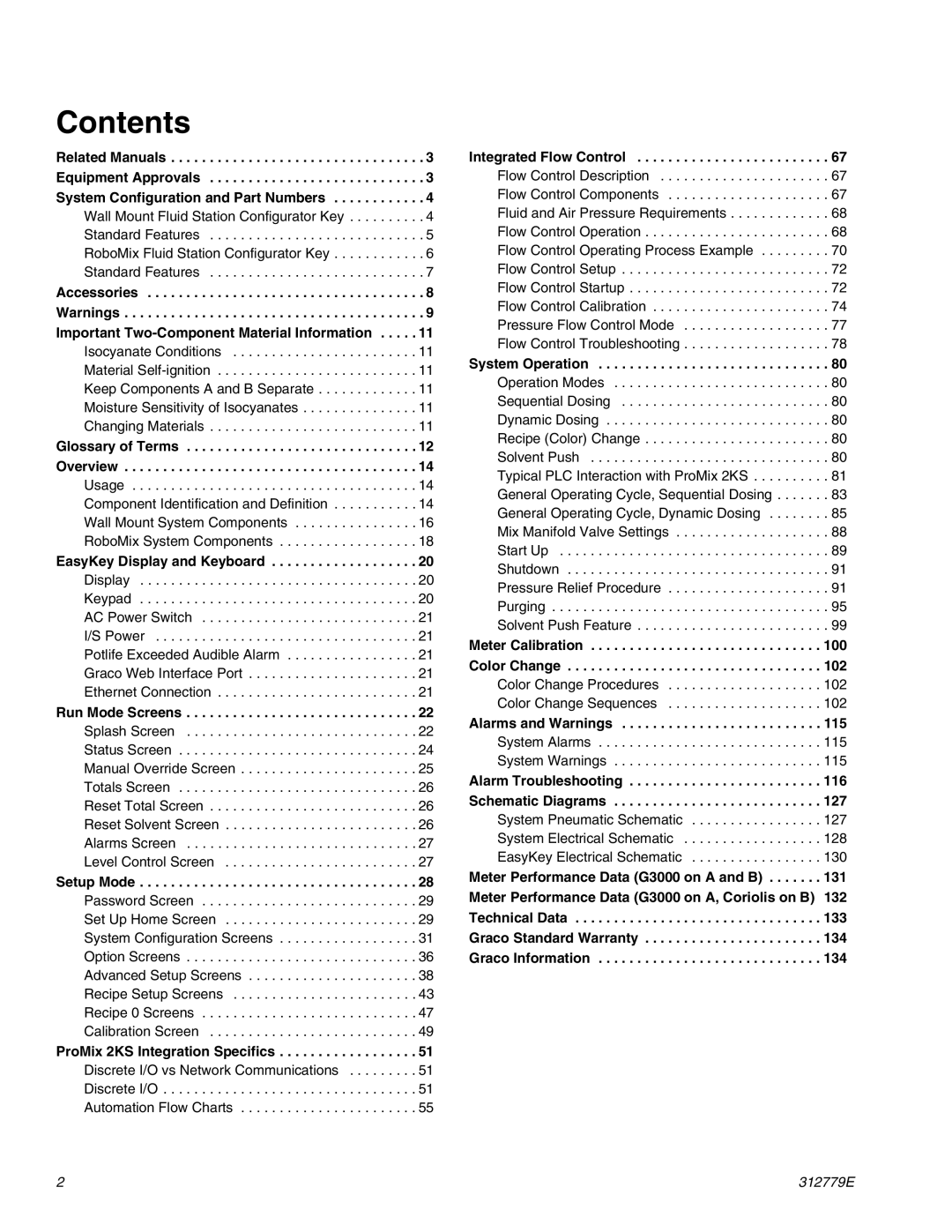

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Configuration and Part Numbers . . . . . . . . . . . . 4

Wall Mount Fluid Station Configurator Key . . . . . . . . . . 4

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

RoboMix Fluid Station Configurator Key . . . . . . . . . . . . 6

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Important Two-Component Material Information . . . . . 11

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . . . . 11

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Keep Components A and B Separate . . . . . . . . . . . . . 11

Moisture Sensitivity of Isocyanates . . . . . . . . . . . . . . . 11

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Component Identification and Definition . . . . . . . . . . . 14

Wall Mount System Components . . . . . . . . . . . . . . . . 16

RoboMix System Components . . . . . . . . . . . . . . . . . . 18

EasyKey Display and Keyboard . . . . . . . . . . . . . . . . . . . 20

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

AC Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

I/S Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Potlife Exceeded Audible Alarm . . . . . . . . . . . . . . . . . 21

Graco Web Interface Port . . . . . . . . . . . . . . . . . . . . . . 21

Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Run Mode Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Splash Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Manual Override Screen . . . . . . . . . . . . . . . . . . . . . . . 25

Totals Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reset Total Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reset Solvent Screen . . . . . . . . . . . . . . . . . . . . . . . . . 26

Alarms Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Level Control Screen . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Password Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Set Up Home Screen . . . . . . . . . . . . . . . . . . . . . . . . . 29

System Configuration Screens . . . . . . . . . . . . . . . . . . 31

Option Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Advanced Setup Screens . . . . . . . . . . . . . . . . . . . . . . 38

Recipe Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . 43

Recipe 0 Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Calibration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

ProMix 2KS Integration Specifics . . . . . . . . . . . . . . . . . . 51

Discrete I/O vs Network Communications . . . . . . . . . 51 Discrete I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 Automation Flow Charts . . . . . . . . . . . . . . . . . . . . . . . 55

Integrated Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . 67

Flow Control Description . . . . . . . . . . . . . . . . . . . . . . 67

Flow Control Components . . . . . . . . . . . . . . . . . . . . . 67

Fluid and Air Pressure Requirements . . . . . . . . . . . . . 68

Flow Control Operation . . . . . . . . . . . . . . . . . . . . . . . . 68

Flow Control Operating Process Example . . . . . . . . . 70

Flow Control Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Flow Control Startup . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Flow Control Calibration . . . . . . . . . . . . . . . . . . . . . . . 74

Pressure Flow Control Mode . . . . . . . . . . . . . . . . . . . 77

Flow Control Troubleshooting . . . . . . . . . . . . . . . . . . . 78

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Sequential Dosing . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Dynamic Dosing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Recipe (Color) Change . . . . . . . . . . . . . . . . . . . . . . . . 80 Solvent Push . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Typical PLC Interaction with ProMix 2KS . . . . . . . . . . 81 General Operating Cycle, Sequential Dosing . . . . . . . 83 General Operating Cycle, Dynamic Dosing . . . . . . . . 85 Mix Manifold Valve Settings . . . . . . . . . . . . . . . . . . . . 88 Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . 91 Purging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 Solvent Push Feature . . . . . . . . . . . . . . . . . . . . . . . . . 99

Meter Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 Color Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Color Change Procedures . . . . . . . . . . . . . . . . . . . . 102 Color Change Sequences . . . . . . . . . . . . . . . . . . . . 102

Alarms and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . 115

System Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 System Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Alarm Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 116 Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

System Pneumatic Schematic . . . . . . . . . . . . . . . . . 127

System Electrical Schematic . . . . . . . . . . . . . . . . . . 128

EasyKey Electrical Schematic . . . . . . . . . . . . . . . . . 130

Meter Performance Data (G3000 on A and B) . . . . . . . 131 Meter Performance Data (G3000 on A, Coriolis on B) 132 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133 Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . 134 Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134