Clean Mixing Module

1.Flush gun according to Clean Spray Gun Procedure, page 20.

2.Connect air supply to gun. Set safety stop to OPEN.

3.Remove air cap by hand.

GX-7A and GX-7 400 Models Only

![]()

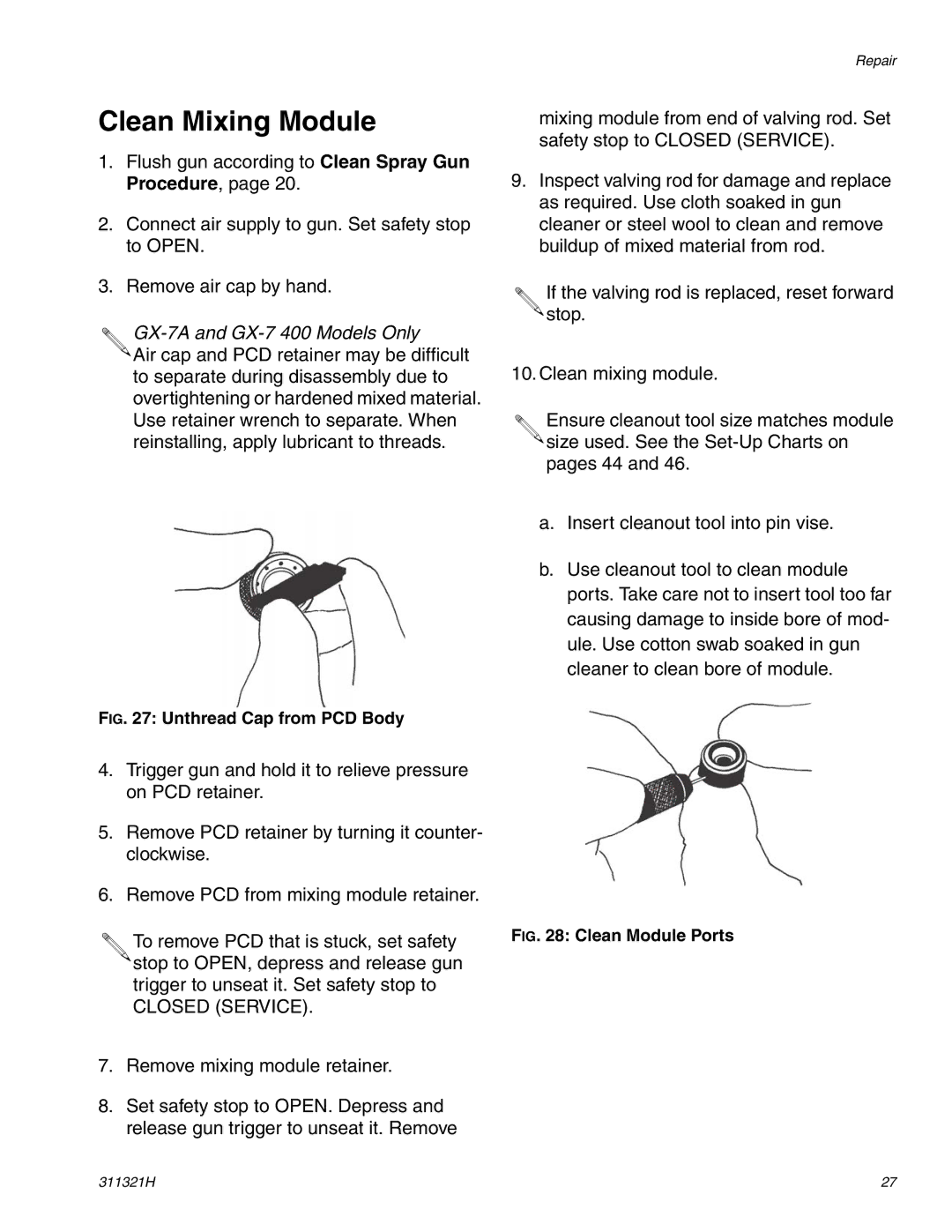

![]() Air cap and PCD retainer may be difficult to separate during disassembly due to overtightening or hardened mixed material. Use retainer wrench to separate. When reinstalling, apply lubricant to threads.

Air cap and PCD retainer may be difficult to separate during disassembly due to overtightening or hardened mixed material. Use retainer wrench to separate. When reinstalling, apply lubricant to threads.

FIG. 27: Unthread Cap from PCD Body

4.Trigger gun and hold it to relieve pressure on PCD retainer.

5.Remove PCD retainer by turning it counter- clockwise.

6.Remove PCD from mixing module retainer.

![]()

![]() To remove PCD that is stuck, set safety

To remove PCD that is stuck, set safety

![]() stop to OPEN, depress and release gun trigger to unseat it. Set safety stop to

stop to OPEN, depress and release gun trigger to unseat it. Set safety stop to

CLOSED (SERVICE).

7.Remove mixing module retainer.

8.Set safety stop to OPEN. Depress and release gun trigger to unseat it. Remove

Repair

mixing module from end of valving rod. Set safety stop to CLOSED (SERVICE).

9.Inspect valving rod for damage and replace as required. Use cloth soaked in gun cleaner or steel wool to clean and remove buildup of mixed material from rod.

If the valving rod is replaced, reset forward ![]()

![]() stop.

stop.

10. Clean mixing module.

Ensure cleanout tool size matches module ![]() size used. See the

size used. See the

pages 44 and 46.

a.Insert cleanout tool into pin vise.

b.Use cleanout tool to clean module ports. Take care not to insert tool too far causing damage to inside bore of mod- ule. Use cotton swab soaked in gun cleaner to clean bore of module.

FIG. 28: Clean Module Ports

311321H | 27 |