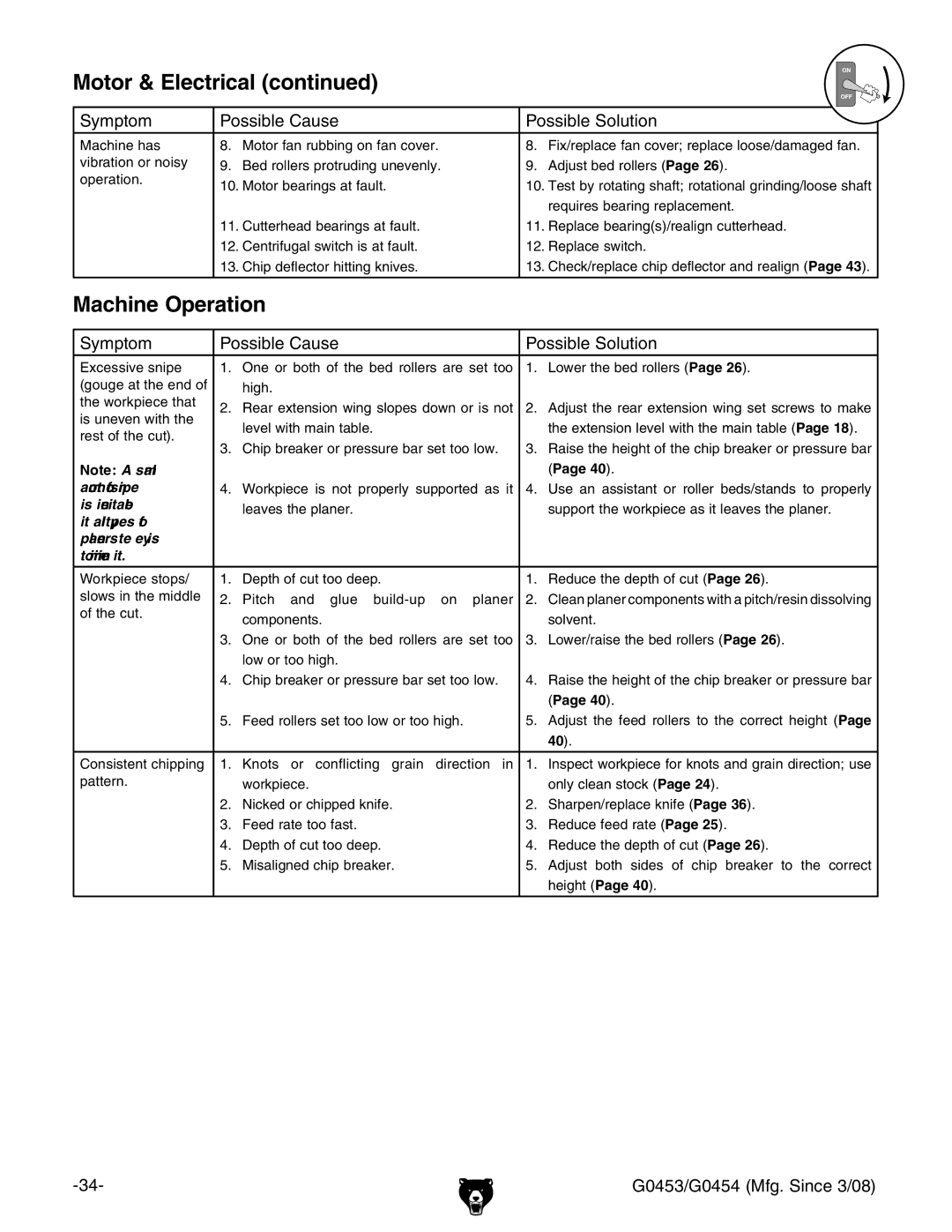

Motor & Electrical (continued)

Symptom | Possible Cause | Possible Solution |

Machine has | 8. Motor fan rubbing on fan cover. | 8. Fix/replace fan cover; replace loose/damaged fan. |

vibration or noisy | 9. Bed rollers protruding unevenly. | 9. Adjust bed rollers (Page 26). |

operation. | 10. Motor bearings at fault. | 10. Test by rotating shaft; rotational grinding/loose shaft |

| ||

|

| requires bearing replacement. |

| 11. Cutterhead bearings at fault. | 11. Replace bearing(s)/realign cutterhead. |

| 12. Centrifugal switch is at fault. | 12. Replace switch. |

| 13. Chip deflector hitting knives. | 13. Check/replace chip deflector and realign (Page 43). |

|

|

|

Machine Operation |

| |

Symptom | Possible Cause | Possible Solution | |||

|

|

|

|

| |

Excessive snipe | 1. | One or both of the bed rollers are set too | 1. | Lower the bed rollers (Page 26). | |

(gouge at the end of |

| high. |

|

| |

the workpiece that | 2. | Rear extension wing slopes down or is not | 2. | Adjust the rear extension wing set screws to make | |

is uneven with the | |||||

| level with main table. |

| the extension level with the main table (Page 18). | ||

rest of the cut). |

|

| |||

3. | Chip breaker or pressure bar set too low. | 3. | Raise the height of the chip breaker or pressure bar | ||

| |||||

Note: A small |

|

|

| (Page 40). | |

amount of snipe | 4. | Workpiece is not properly supported as it | 4. | Use an assistant or roller beds/stands to properly | |

is inevitable |

| leaves the planer. |

| support the workpiece as it leaves the planer. | |

with all types of |

|

| |||

|

|

|

| ||

|

|

|

|

| |

to minimize it. |

|

|

|

| |

|

|

|

|

| |

Workpiece stops/ | 1. | Depth of cut too deep. | 1. | Reduce the depth of cut (Page 26). | |

slows in the middle | 2. | Pitch and glue | 2. | Clean planer components with a pitch/resin dissolving | |

of the cut. |

| components. |

| solvent. | |

|

|

| |||

| 3. | One or both of the bed rollers are set too | 3. | Lower/raise the bed rollers (Page 26). | |

|

| low or too high. |

|

| |

| 4. | Chip breaker or pressure bar set too low. | 4. | Raise the height of the chip breaker or pressure bar | |

|

|

|

| (Page 40). | |

| 5. | Feed rollers set too low or too high. | 5. | Adjust the feed rollers to the correct height (Page | |

|

|

|

| 40). | |

|

|

|

|

| |

Consistent chipping | 1. | Knots or conflicting grain direction in | 1. | Inspect workpiece for knots and grain direction; use | |

pattern. |

| workpiece. |

| only clean stock (Page 24). | |

| 2. | Nicked or chipped knife. | 2. | Sharpen/replace knife (Page 36). | |

| 3. | Feed rate too fast. | 3. | Reduce feed rate (Page 25). | |

| 4. | Depth of cut too deep. | 4. | Reduce the depth of cut (Page 26). | |

| 5. | Misaligned chip breaker. | 5. | Adjust both sides of chip breaker to the correct | |

|

|

|

| height (Page 40). | |

|

|

|

|

| |

G0453/G0454 (Mfg. Since 3/08) |