4.If the distance measured in Step 3 is not equal to 1⁄4", then loosen the four hex bolts that secure the chip deflector and adjust the gap to 1⁄4".

5.

Scale Calibration

Although correctly set at the factory, the scale can be adjusted for accuracy if it becomes neces- sary.

Tools Needed | Qty |

Phillips Screwdriver #2 | 1 |

Scrap Piece of Stock | 1 |

Calipers | 1 |

To |

|

1.Plane the scrap piece of stock until it is flat and of even thickness along its length.

Note: Turn the board over between each pass.

2.Use calipers to measure the board thick- ness.

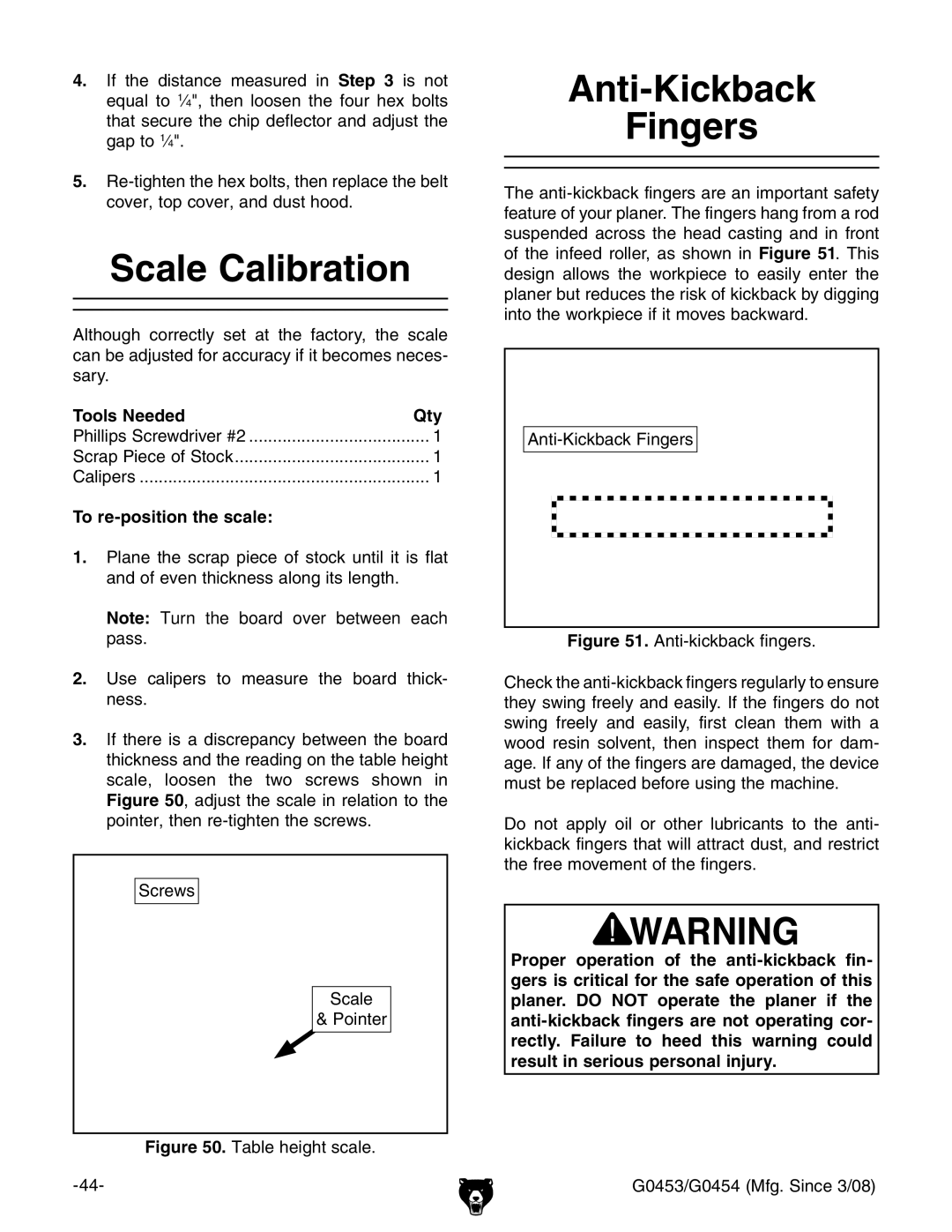

3.If there is a discrepancy between the board thickness and the reading on the table height scale, loosen the two screws shown in Figure 50, adjust the scale in relation to the pointer, then

Screws![]()

Scale

& Pointer

Figure 50. Table height scale.

Anti-Kickback

Fingers

The

Figure 51. Anti-kickback fingers.

Check the anti-kickback fingers regularly to ensure they swing freely and easily. If the fingers do not swing freely and easily, first clean them with a wood resin solvent, then inspect them for dam- age. If any of the fingers are damaged, the device must be replaced before using the machine.

Do not apply oil or other lubricants to the anti- kickback fingers that will attract dust, and restrict the free movement of the fingers.

Proper operation of the

G0453/G0454 (Mfg. Since 3/08)