6.Look at the face of the support bearing and rotate the blade guide assembly

�������

![]() �����

�����

�������

�������

Figure 21. Blade should be perpendicular (90˚)

to the face of the support bearing.

7.Tighten the lock bolt.

8.Loosen the thumbscrew on the support bear- ing adjustment shaft.

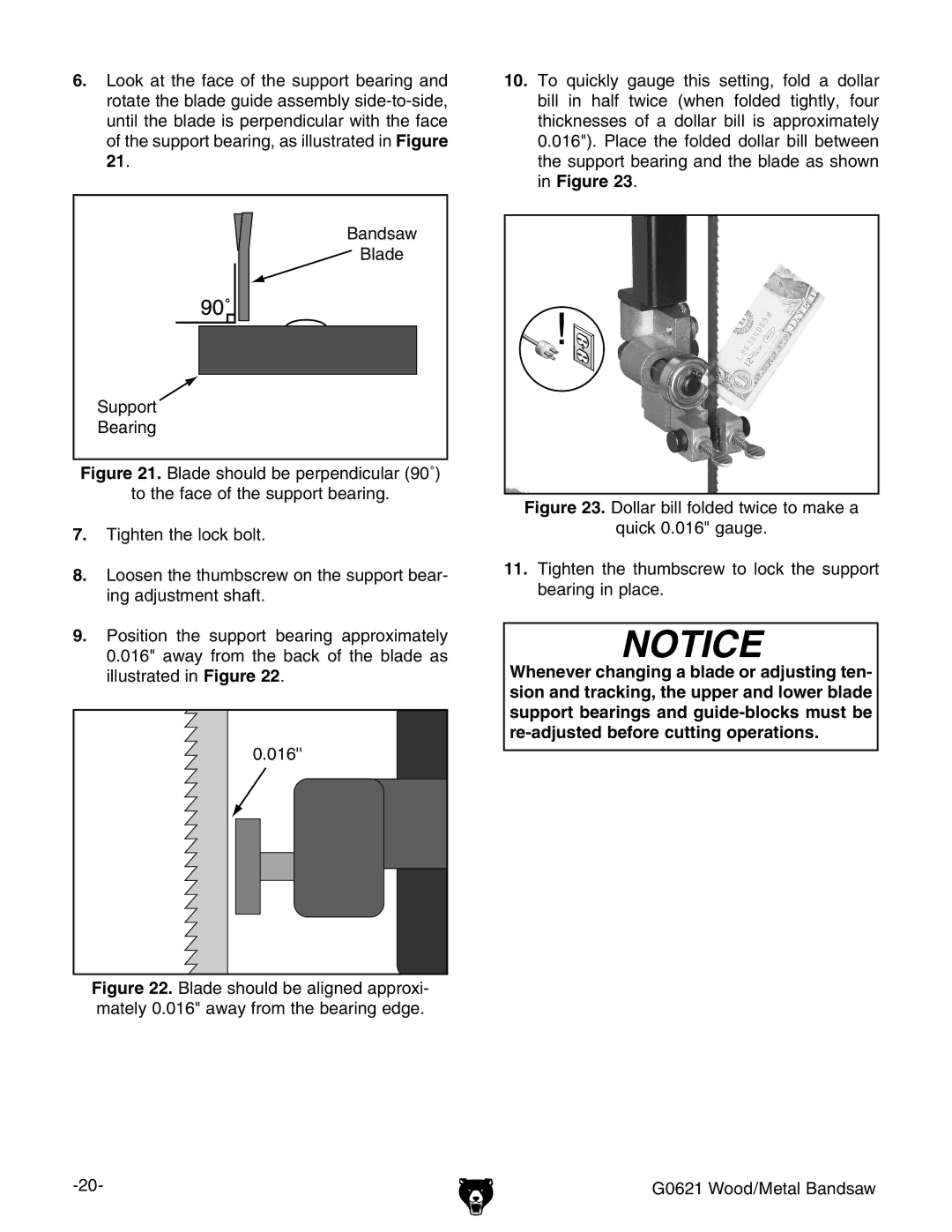

9.Position the support bearing approximately 0.016" away from the back of the blade as illustrated in Figure 22.

0.016''

Figure 22. Blade should be aligned approxi- mately 0.016" away from the bearing edge.

10.To quickly gauge this setting, fold a dollar bill in half twice (when folded tightly, four thicknesses of a dollar bill is approximately 0.016"). Place the folded dollar bill between the support bearing and the blade as shown in Figure 23.

Figure 23. Dollar bill folded twice to make a

quick 0.016" gauge.

11.Tighten the thumbscrew to lock the support bearing in place.

NOTICE

Whenever changing a blade or adjusting ten- sion and tracking, the upper and lower blade support bearings and

G0621 Wood/Metal Bandsaw |