Resawing

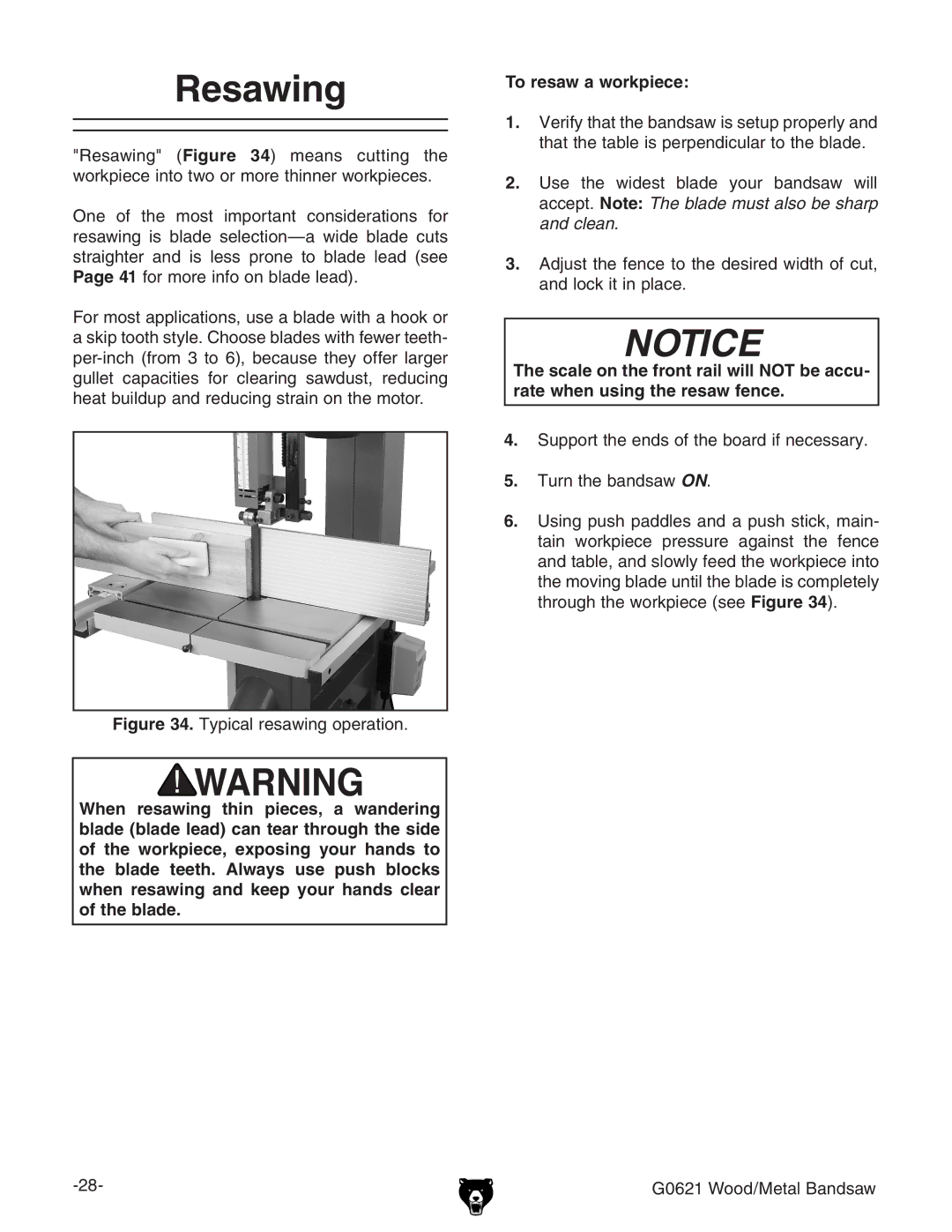

"Resawing" (Figure 34) means cutting the workpiece into two or more thinner workpieces.

One of the most important considerations for resawing is blade

For most applications, use a blade with a hook or a skip tooth style. Choose blades with fewer teeth-

Figure 34. Typical resawing operation.

When resawing thin pieces, a wandering blade (blade lead) can tear through the side of the workpiece, exposing your hands to the blade teeth. Always use push blocks when resawing and keep your hands clear of the blade.

To resaw a workpiece:

1.Verify that the bandsaw is setup properly and that the table is perpendicular to the blade.

2.Use the widest blade your bandsaw will accept. Note: The blade must also be sharp and clean.

3.Adjust the fence to the desired width of cut, and lock it in place.

NOTICE

The scale on the front rail will NOT be accu- rate when using the resaw fence.

4.Support the ends of the board if necessary.

5.Turn the bandsaw ON.

6.Using push paddles and a push stick, main- tain workpiece pressure against the fence and table, and slowly feed the workpiece into the moving blade until the blade is completely through the workpiece (see Figure 34).

G0621 Wood/Metal Bandsaw |