4.Flip the completed roller tables onto their feet and place them on either side of the saw, as shown in Figure 16.

Figure 16. Positioning roller tables.

5.Place a long straightedge across the saw table and roller tables and adjust the legs so that the roller tables are even with the saw table.

6.Tighten all (16) leg cap screws.

Required

Adjustments

To ensure your safety and to prevent damage to the machine, you must adjust the blade tension before the Test Run.

Blade tension (Page 36) is not set at the factory to prevent unnecessary stress on the blade dur- ing shipping. If the Test Run is performed without first properly tensioning the blade, the blade may come off, resulting in personal injury or damage to the blade or machine.

To properly tension the blade, turn the blade ten- sion handwheel until the blade tension gauge reads between 25,000 and 28,000 PSI (Page 36).

Coolant Reservoir

Cover/Catch Tray

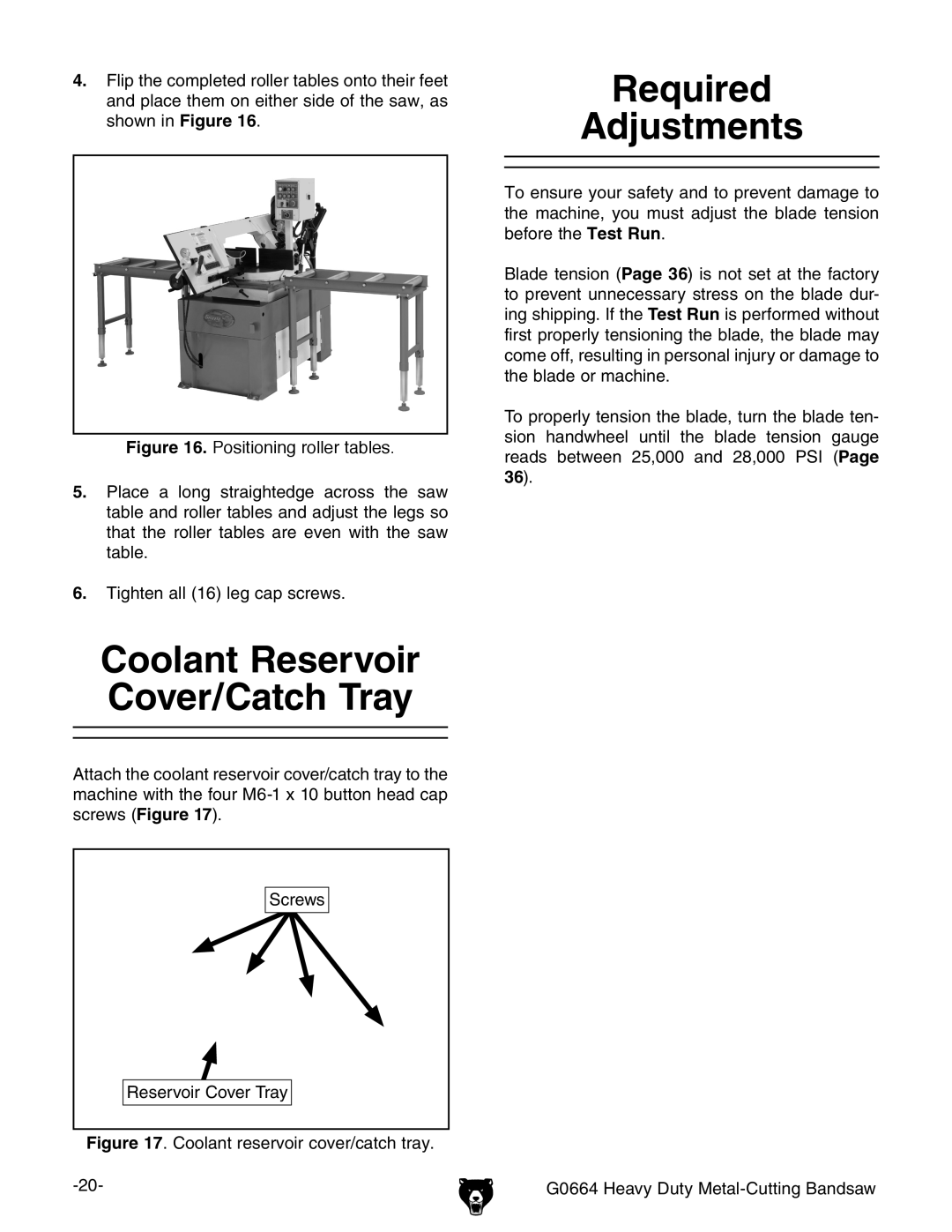

Attach the coolant reservoir cover/catch tray to the machine with the four

Screws

Reservoir Cover Tray

Figure 17. Coolant reservoir cover/catch tray.

G0664 Heavy Duty |