Swivel Stops

The blade swivel stops are factory set. However, due to shipping and storage we recommend that you check the 0°,

To adjust the swivel stops:

1.Make sure the blade is oiled, tensioned, and tracking correctly, and that the guides are set.

2.DISCONNECT BANDSAW FROM POWER!

3.Raise the bow, move and lock the headstock to 0° (Figure 60), then lower the bow.

0° Mark

Figure 60. Bow and headstock moved to zero.

4.Observe the scale, and if the headstock is not at 0°, adjust the zero stop (Figure 61) so it will line up with the mark.

Zero Stop

Figure 61. Zero degree swivel stop.

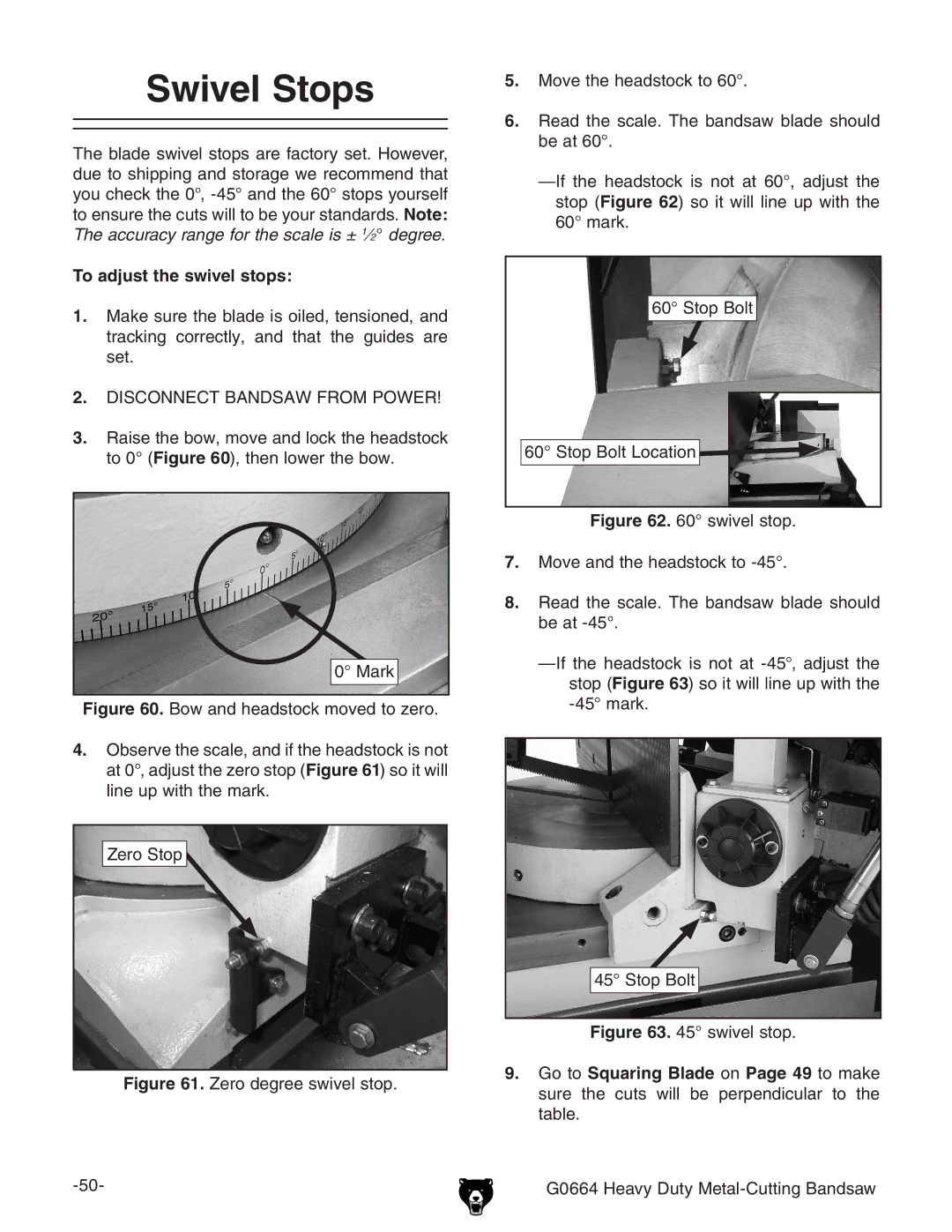

5.Move the headstock to 60°.

6.Read the scale. The bandsaw blade should be at 60°.

—If the headstock is not at 60°, adjust the stop (Figure 62) so it will line up with the 60° mark.

60° Stop Bolt |

60° Stop Bolt Location |