Headstock Turret

Rotation

The turret rotates 360° around the column (see Figure 26).

Turret

Figure 26. Headstock turret rotated 45° to the

left.

Tools Needed | Qty |

Wrench 19mm | 1 |

To rotate the turret: |

|

1.DISCONNECT MILL FROM POWER!

Always lock the turret firmly in place after adjusting the rotation. Unexpected move- ment of the head during operations could cause the cutter to bind with the workpiece causing damage to the cutter and workpiece, and possible personal injury.

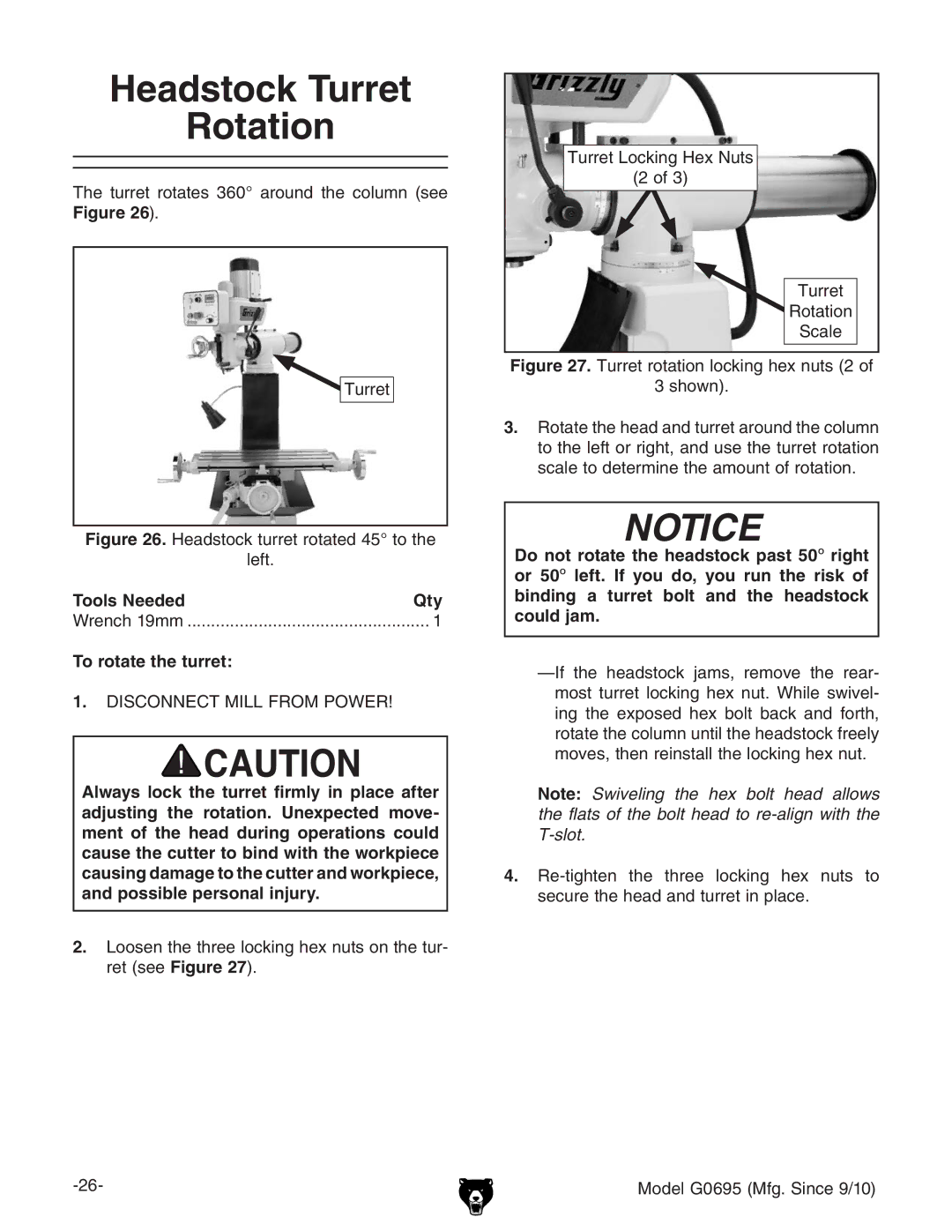

2.Loosen the three locking hex nuts on the tur- ret (see Figure 27).

Turret Locking Hex Nuts |

(2 of 3) |

Turret |

Rotation |

Scale |

Figure 27. Turret rotation locking hex nuts (2 of

3shown).

3.Rotate the head and turret around the column to the left or right, and use the turret rotation scale to determine the amount of rotation.

NOTICE

Do not rotate the headstock past 50º right or 50º left. If you do, you run the risk of binding a turret bolt and the headstock could jam.

Note: Swiveling the hex bolt head allows the flats of the bolt head to

4.

Model G0695 (Mfg. Since 9/10) |