Always get an assistant to help you tilt the headstock or tighten the headstock lock nuts during the following steps. The head- stock is very heavy and may be difficult to control once it is tilted past 45ºR or 45ºL.

If you do not pay attention, it can flip over, causing serious personal injury and pos- sible machine damage.

5.Determine which of the two hex bolts that lock the headstock vertically is loose.

6.Tighten the locking hex nut on the opposite side of the headstock to secure it.

7.Remove the hex nut and flat washer from the hex bolt that is loose.

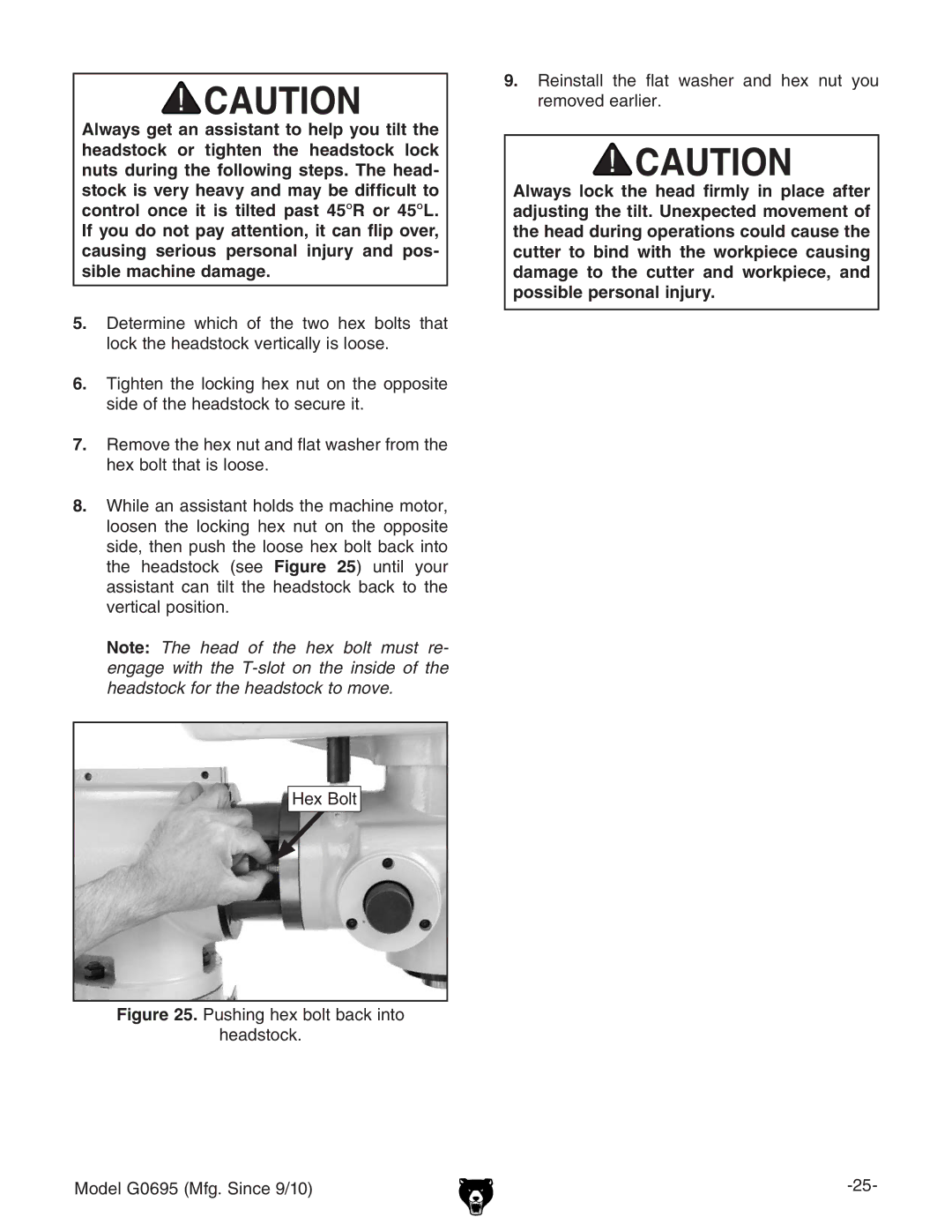

8.While an assistant holds the machine motor, loosen the locking hex nut on the opposite side, then push the loose hex bolt back into the headstock (see Figure 25) until your assistant can tilt the headstock back to the vertical position.

Note: The head of the hex bolt must re- engage with the

9.Reinstall the flat washer and hex nut you removed earlier.

Always lock the head firmly in place after adjusting the tilt. Unexpected movement of the head during operations could cause the cutter to bind with the workpiece causing damage to the cutter and workpiece, and possible personal injury.

Hex Bolt

Figure 25. Pushing hex bolt back into

headstock.

Model G0695 (Mfg. Since 9/10) |