Leadscrews

Lubricant | Frequency | Qty |

NLGI #2 Grease | Every | Thin |

| 40 Hours | Coat |

| of Operation |

|

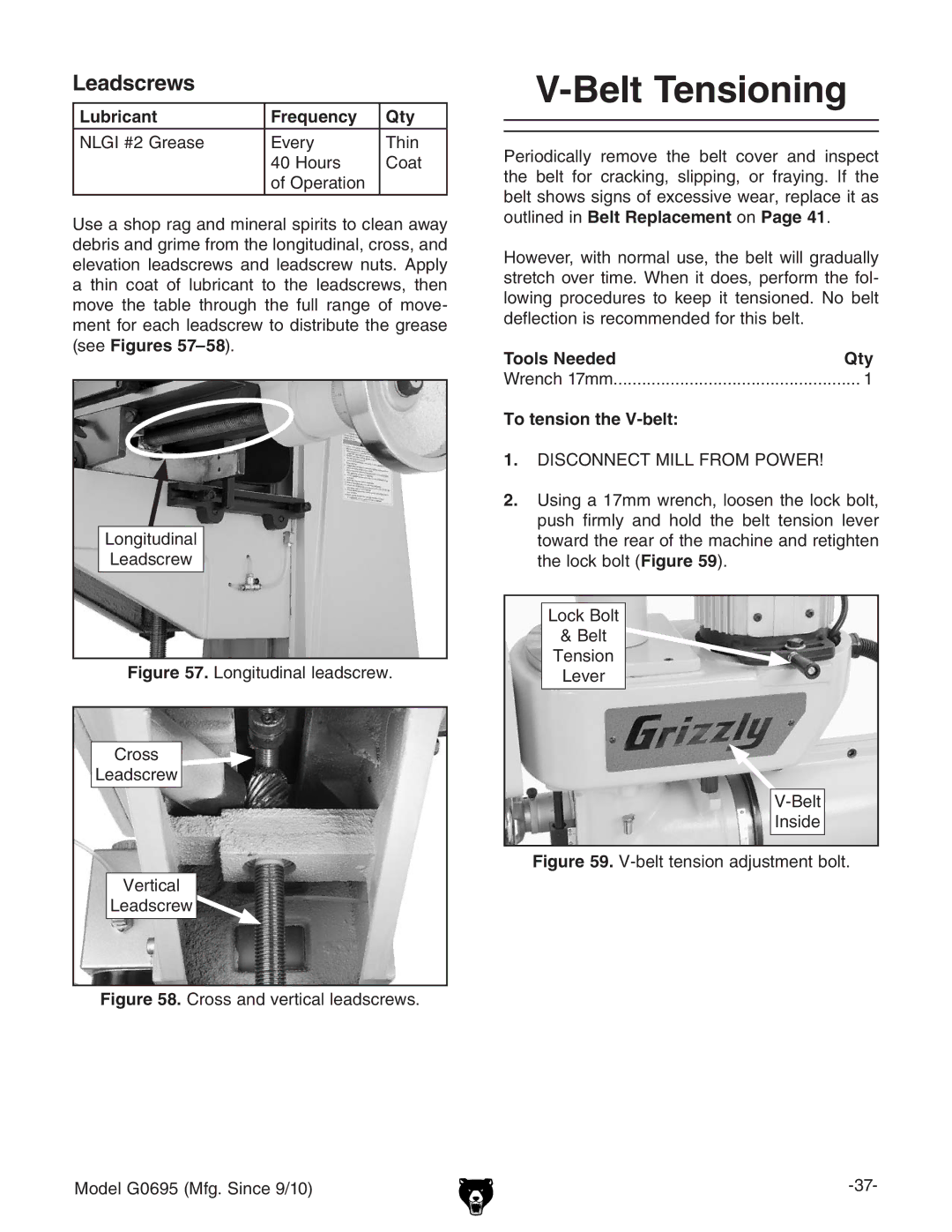

Use a shop rag and mineral spirits to clean away debris and grime from the longitudinal, cross, and elevation leadscrews and leadscrew nuts. Apply a thin coat of lubricant to the leadscrews, then move the table through the full range of move- ment for each leadscrew to distribute the grease (see Figures

Longitudinal

Leadscrew

Figure 57. Longitudinal leadscrew.

Cross

Leadscrew

Vertical

Leadscrew![]()

Figure 58. Cross and vertical leadscrews.

V-Belt Tensioning

Periodically remove the belt cover and inspect the belt for cracking, slipping, or fraying. If the belt shows signs of excessive wear, replace it as outlined in Belt Replacement on Page 41.

However, with normal use, the belt will gradually stretch over time. When it does, perform the fol- lowing procedures to keep it tensioned. No belt deflection is recommended for this belt.

Tools Needed | Qty |

Wrench 17mm | 1 |

To tension the V-belt:

1.DISCONNECT MILL FROM POWER!

2.Using a 17mm wrench, loosen the lock bolt, push firmly and hold the belt tension lever toward the rear of the machine and retighten the lock bolt (Figure 59).

Lock Bolt |

& Belt |

Tension |

Lever |

Inside |

Figure 59. V-belt tension adjustment bolt.

Model G0695 (Mfg. Since 9/10) |