NOTICE

Failure to follow the lubrication practices outlined in this manual could lead to pre- mature failure of your mill and void the war- ranty.

One-Shot Oiler

Lubricant | Frequency | Qty |

ISO 68 Lubricant or | Every | 1 |

Equivalent | 8 Hours | Pump |

| of Operation |

|

|

|

|

The oil lines running from the

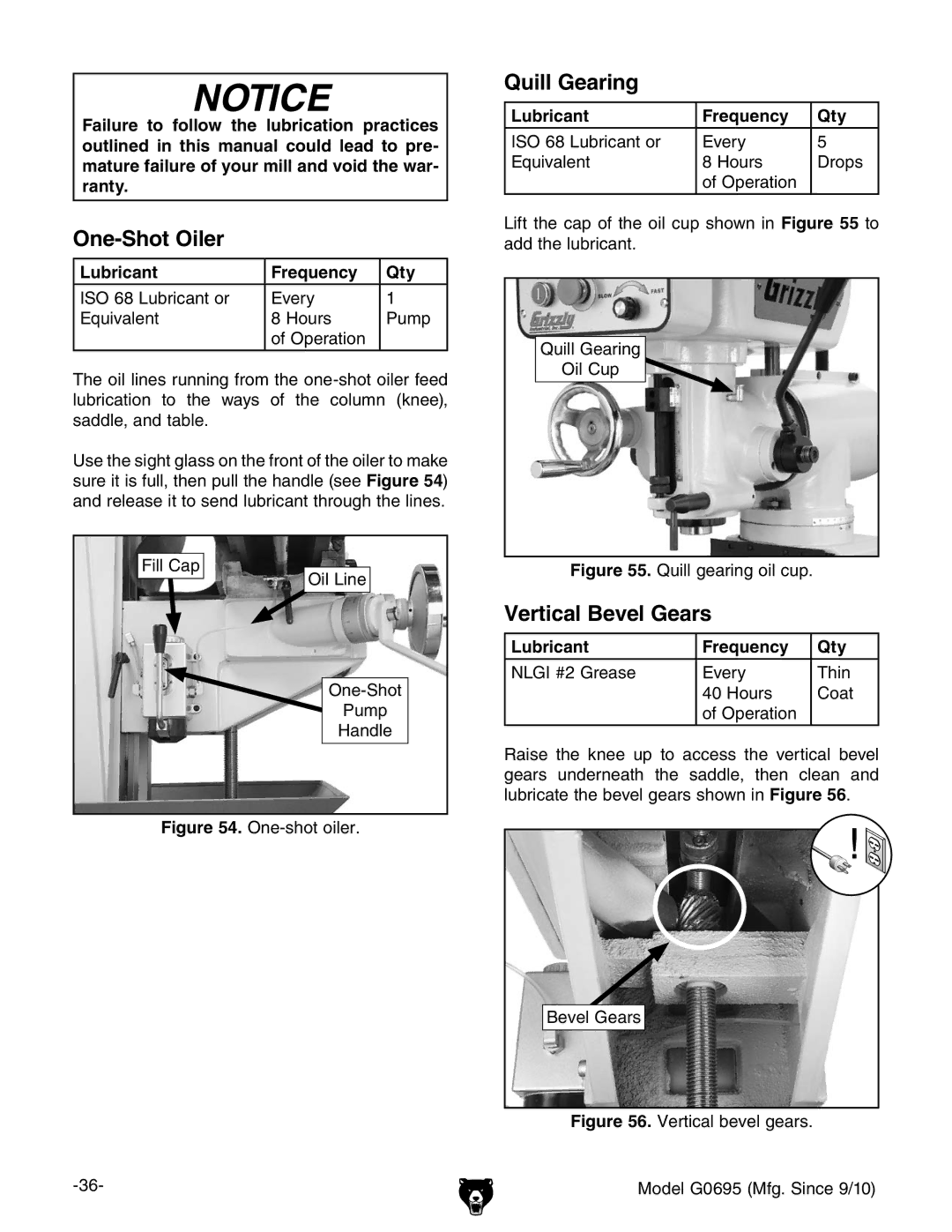

Use the sight glass on the front of the oiler to make sure it is full, then pull the handle (see Figure 54) and release it to send lubricant through the lines.

Fill Cap

Oil Line

Pump

Handle

Figure 54. One-shot oiler.

Quill Gearing

Lubricant | Frequency | Qty |

ISO 68 Lubricant or | Every | 5 |

Equivalent | 8 Hours | Drops |

| of Operation |

|

|

|

|

Lift the cap of the oil cup shown in Figure 55 to add the lubricant.

Quill Gearing

Oil Cup

Figure 55. Quill gearing oil cup.

Vertical Bevel Gears

Lubricant | Frequency | Qty |

NLGI #2 Grease | Every | Thin |

| 40 Hours | Coat |

| of Operation |

|

|

|

|

Raise the knee up to access the vertical bevel gears underneath the saddle, then clean and lubricate the bevel gears shown in Figure 56.

Bevel Gears