To shim the trunnion:

1.Loosen the trunnion bolts.

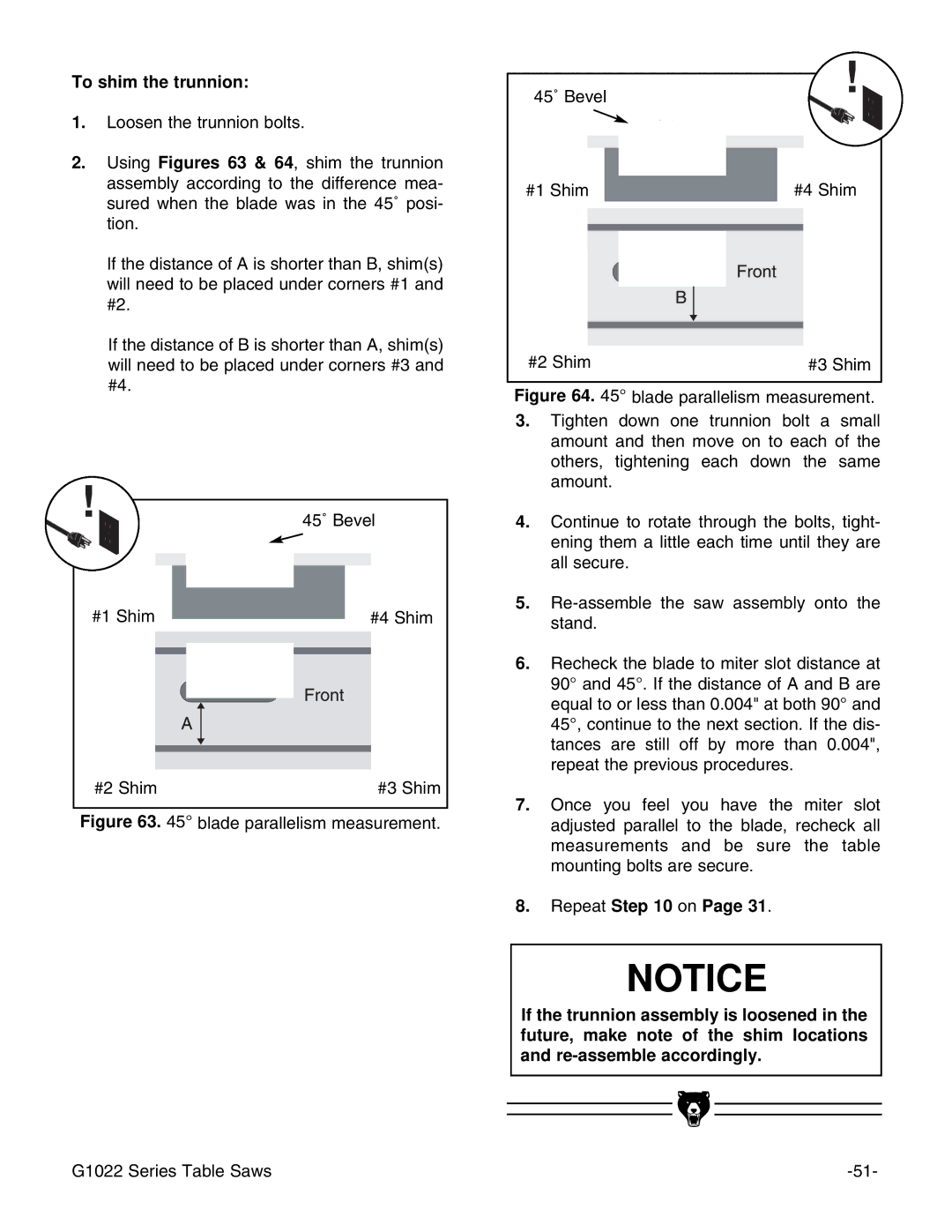

2.Using Figures 63 & 64, shim the trunnion assembly according to the difference mea- sured when the blade was in the 45û posi- tion.

If the distance of A is shorter than B, shim(s) will need to be placed under corners #1 and #2.

If the distance of B is shorter than A, shim(s) will need to be placed under corners #3 and #4.

!

45û Bevel

#1 Shim | #4 Shim |

#2 Shim | #3 Shim |

Figure 63. 45¡ blade parallelism measurement.

45û Bevel | ! |

#1 Shim | #4 Shim |

#2 Shim | #3 Shim |

Figure 64. 45¡ blade parallelism measurement.

3.Tighten down one trunnion bolt a small amount and then move on to each of the others, tightening each down the same amount.

4.Continue to rotate through the bolts, tight- ening them a little each time until they are all secure.

5.Re-assemble the saw assembly onto the stand.

6.Recheck the blade to miter slot distance at 90¡ and 45¡. If the distance of A and B are equal to or less than 0.004" at both 90¡ and 45¡, continue to the next section. If the dis- tances are still off by more than 0.004", repeat the previous procedures.

7.Once you feel you have the miter slot adjusted parallel to the blade, recheck all measurements and be sure the table mounting bolts are secure.

8.Repeat Step 10 on Page 31.

NOTICE

If the trunnion assembly is loosened in the future, make note of the shim locations and

|

|

|

|

|

|

|

|

|

|

|

|

G1022 Series Table Saws | |||