Avoiding Kickback | Safety Accessories | |

|

|

|

|

|

|

Failure to understand how and why kick- back occurs could cause serious person- al injury. DO NOT operate this table saw if you do not have a clear understanding of kickback, and how it occurs.

Statistics prove that most common accidents among table saw users can be linked to kick- back.

Kickback is typically defined as the

In addition to the danger of the operator or oth- ers in the area being struck by the flying stock, it is often the case that the operatorÕs hands are forced into the blade during the kickback.

The following can help minimize kickbacks:

¥Use your blade guard and splitter.

¥Never for any reason place your hand behind the blade. Should kickback occur, your hand will be pulled into the blade.

¥Inspect splitter for alignment between it and your blade.

¥Never use the fence as a guide for crosscut- ting.

¥Never attempt freehand cuts.

¥Use a push stick or featherboard to maintain control of your workpiece.

¥Feed cuts through to completion.

¥Stand to the side when ripping.

¥Ensure your fence and miter slot are parallel to the blade.

If you do not have a clear understanding of kick- back and how it occurs, do not operate this table saw.

Not using safety accessories could cause serious personal injury. Learn how to cor- rectly use each safety accessory.

Push Sticks

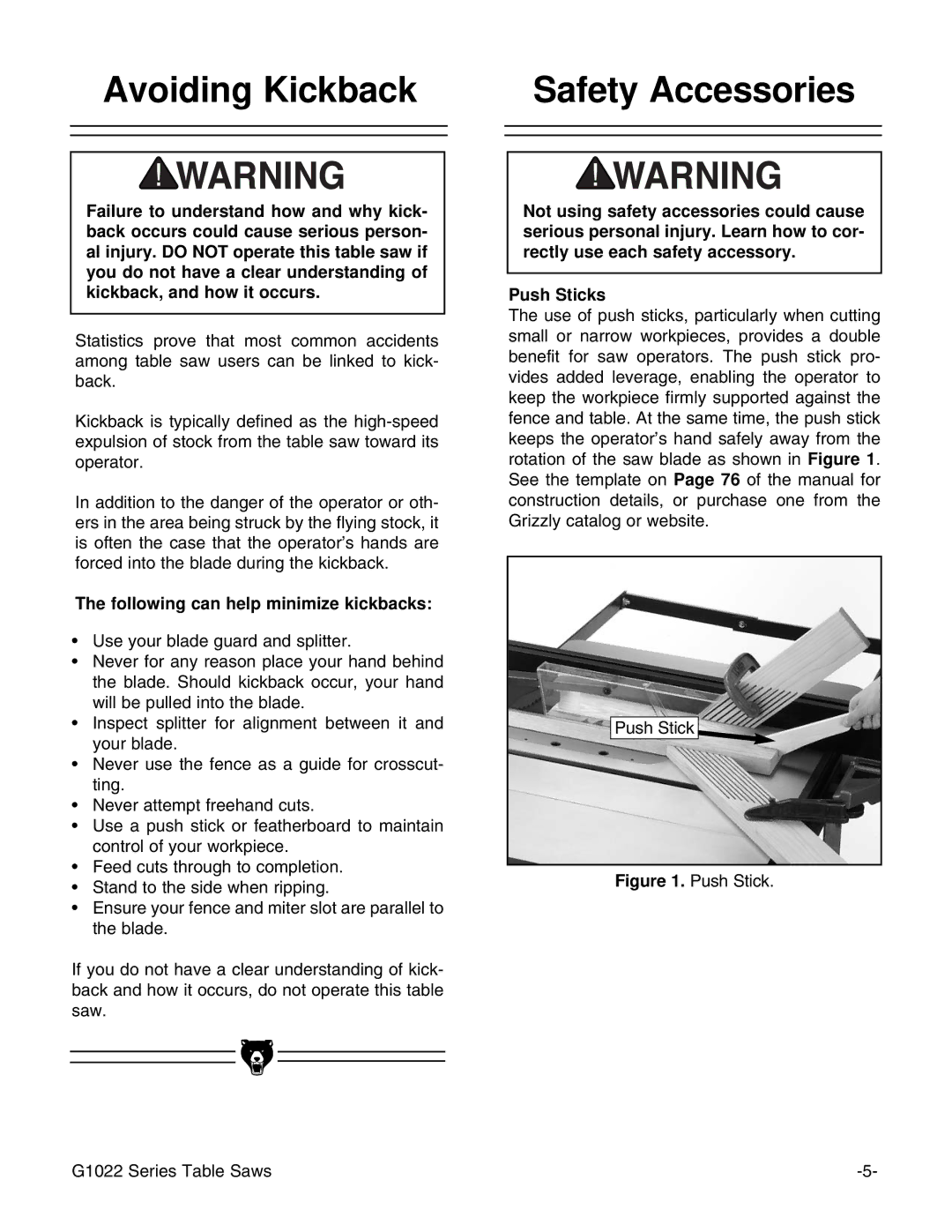

The use of push sticks, particularly when cutting small or narrow workpieces, provides a double benefit for saw operators. The push stick pro- vides added leverage, enabling the operator to keep the workpiece firmly supported against the fence and table. At the same time, the push stick keeps the operatorÕs hand safely away from the rotation of the saw blade as shown in Figure 1. See the template on Page 76 of the manual for construction details, or purchase one from the Grizzly catalog or website.

Push Stick

Figure 1. Push Stick.

|

|

|

|

|

|

|

|

|

|

|

|

G1022 Series Table Saws | |||