|

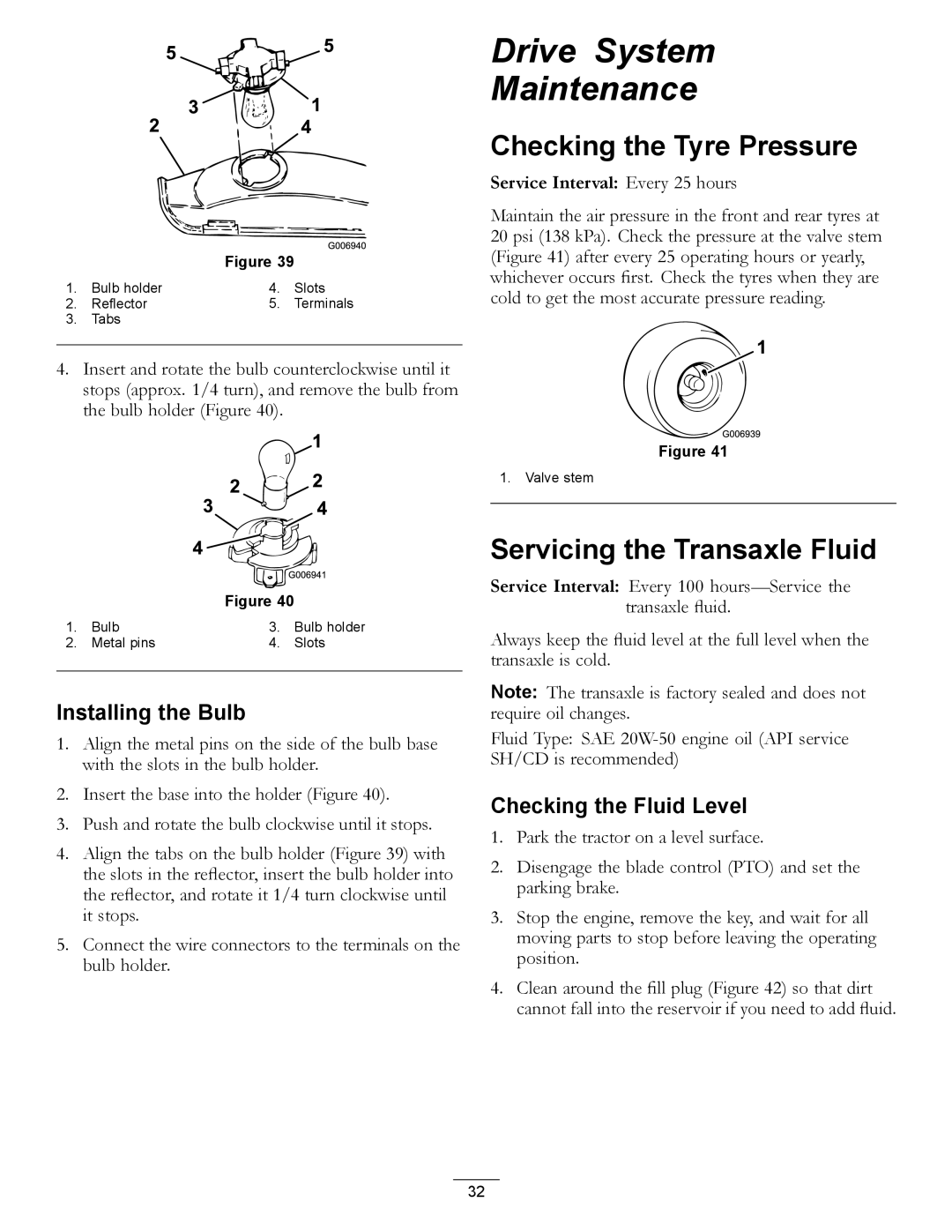

| Figure 39 |

|

1. | Bulb holder | 4. | Slots |

2. | Reflector | 5. | Terminals |

3.Tabs

4.Insert and rotate the bulb counterclockwise until it stops (approx. 1/4 turn), and remove the bulb from the bulb holder (Figure 40).

Drive System

Maintenance

Checking the Tyre Pressure

Service Interval: Every 25 hours

Maintain the air pressure in the front and rear tyres at 20 psi (138 kPa). Check the pressure at the valve stem (Figure 41) after every 25 operating hours or yearly, whichever occurs first. Check the tyres when they are cold to get the most accurate pressure reading.

Figure 41

1. Valve stem

|

| Figure 40 |

|

1. | Bulb | 3. | Bulb holder |

2. | Metal pins | 4. | Slots |

|

|

|

|

Installing the Bulb

1.Align the metal pins on the side of the bulb base with the slots in the bulb holder.

2.Insert the base into the holder (Figure 40).

3.Push and rotate the bulb clockwise until it stops.

4.Align the tabs on the bulb holder (Figure 39) with the slots in the reflector, insert the bulb holder into the reflector, and rotate it 1/4 turn clockwise until it stops.

5.Connect the wire connectors to the terminals on the bulb holder.

Servicing the Transaxle Fluid

Service Interval: Every 100

Always keep the fluid level at the full level when the transaxle is cold.

Note: The transaxle is factory sealed and does not require oil changes.

Fluid Type: SAE

Checking the Fluid Level

1.Park the tractor on a level surface.

2.Disengage the blade control (PTO) and set the parking brake.

3.Stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating position.

4.Clean around the fill plug (Figure 42) so that dirt cannot fall into the reservoir if you need to add fluid.

32