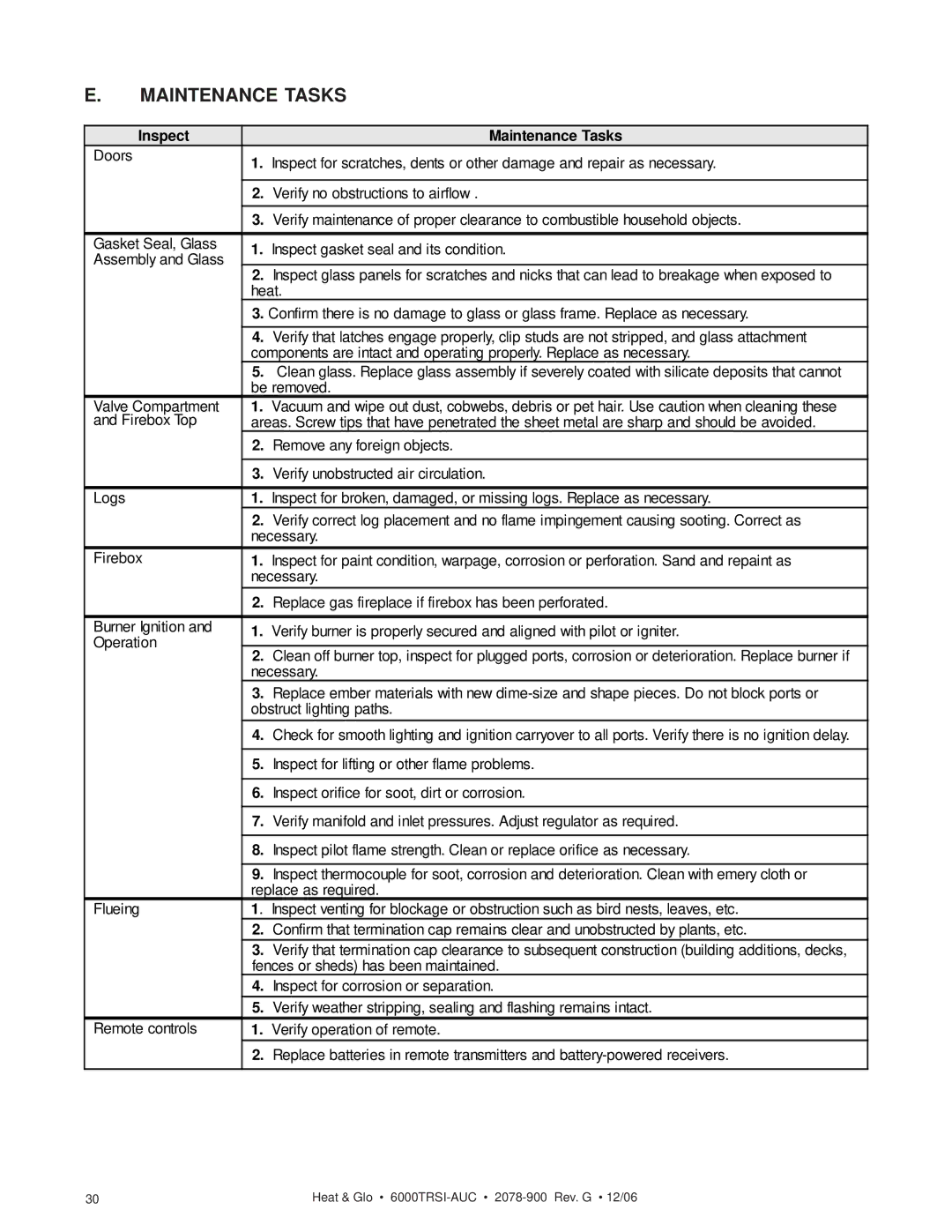

E.MAINTENANCE TASKS

Inspect |

| Maintenance Tasks | |

Doors | 1. Inspect for scratches, dents or other damage and repair as necessary. | ||

| |||

|

|

| |

| 2. | Verify no obstructions to airflow . | |

| 3. | Verify maintenance of proper clearance to combustible household objects. | |

Gasket Seal, Glass | 1. Inspect gasket seal and its condition. | ||

Assembly and Glass | |||

|

| ||

| 2. | Inspect glass panels for scratches and nicks that can lead to breakage when exposed to | |

| heat. | ||

| 3. Confirm there is no damage to glass or glass frame. Replace as necessary. | ||

|

|

| |

| 4. | Verify that latches engage properly, clip studs are not stripped, and glass attachment | |

| components are intact and operating properly. Replace as necessary. | ||

| 5. | Clean glass. Replace glass assembly if severely coated with silicate deposits that cannot | |

| be removed. | ||

Valve Compartment | 1. Vacuum and wipe out dust, cobwebs, debris or pet hair. Use caution when cleaning these | ||

and Firebox Top | areas. Screw tips that have penetrated the sheet metal are sharp and should be avoided. | ||

| 2. | Remove any foreign objects. | |

|

|

| |

| 3. | Verify unobstructed air circulation. | |

|

|

| |

Logs | 1. | Inspect for broken, damaged, or missing logs. Replace as necessary. | |

| 2. | Verify correct log placement and no flame impingement causing sooting. Correct as | |

| necessary. | ||

Firebox | 1. | Inspect for paint condition, warpage, corrosion or perforation. Sand and repaint as | |

| necessary. | ||

| 2. | Replace gas fireplace if firebox has been perforated. | |

|

|

| |

Burner Ignition and | 1. | Verify burner is properly secured and aligned with pilot or igniter. | |

Operation |

|

| |

2. | Clean off burner top, inspect for plugged ports, corrosion or deterioration. Replace burner if | ||

| |||

| necessary. | ||

| 3. | Replace ember materials with new | |

| obstruct lighting paths. | ||

| 4. | Check for smooth lighting and ignition carryover to all ports. Verify there is no ignition delay. | |

|

|

| |

| 5. | Inspect for lifting or other flame problems. | |

|

|

| |

| 6. | Inspect orifice for soot, dirt or corrosion. | |

|

|

| |

| 7. | Verify manifold and inlet pressures. Adjust regulator as required. | |

|

|

| |

| 8. | Inspect pilot flame strength. Clean or replace orifice as necessary. | |

|

|

| |

| 9. | Inspect thermocouple for soot, corrosion and deterioration. Clean with emery cloth or | |

| replace as required. | ||

Flueing | 1. Inspect venting for blockage or obstruction such as bird nests, leaves, etc. | ||

| 2. | Confirm that termination cap remains clear and unobstructed by plants, etc. | |

| 3. | Verify that termination cap clearance to subsequent construction (building additions, decks, | |

| fences or sheds) has been maintained. | ||

| 4. | Inspect for corrosion or separation. | |

| 5. | Verify weather stripping, sealing and flashing remains intact. | |

Remote controls | 1. | Verify operation of remote. | |

| 2. | Replace batteries in remote transmitters and | |

|

|

| |

30 | Heat & Glo • |