Installation, Operation & Maintenance | HTV/HTD/HTH SERIES | Heat Controller, Inc. |

Electrical - Line Voltage

WARNING!

WARNING! Disconnect electrical power source to prevent injury or death from electrical shock.

CAUTION!

CAUTION! Use only copper conductors for field installed electrical wiring. Unit terminals are not designed to accept other types of conductors.

Electrical - Line Voltage

All field installed wiring, including electrical ground, must comply with the National Electrical Code as well as all applicable local codes. Refer to the unit electrical data for fuse sizes. Consult wiring diagram for field connections that must be made by the installing (or electrical) contractor.

All final electrical connections must be made with a length of

flexible conduit to minimize vibration and sound transmission to the building.

General Line Voltage Wiring

Be sure the available power is the same voltage and phase shown on the unit serial plate. Line and low voltage wiring must be done in accordance with local codes or the National Electric Code, whichever is applicable.

Power Connection

Line voltage connection is made by connecting the incoming line voltage wires to the “L” side of the contactor as shown in Figure 16. Consult Tables 4a through 4b for correct fuse size.

208 Volt Operation

All residential

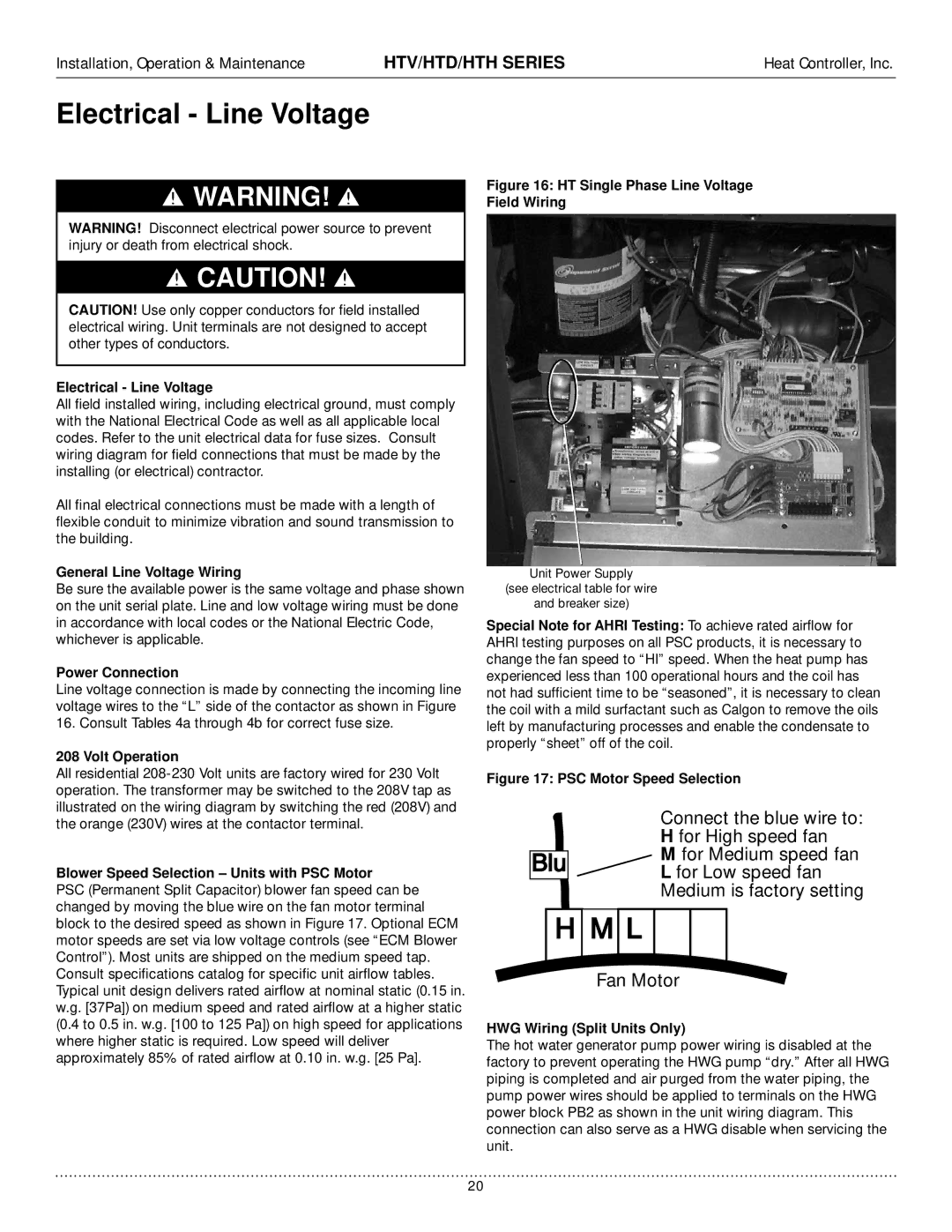

Blower Speed Selection – Units with PSC Motor

PSC (Permanent Split Capacitor) blower fan speed can be changed by moving the blue wire on the fan motor terminal block to the desired speed as shown in Figure 17. Optional ECM motor speeds are set via low voltage controls (see “ECM Blower Control”). Most units are shipped on the medium speed tap. Consult specifications catalog for specific unit airflow tables. Typical unit design delivers rated airflow at nominal static (0.15 in. w.g. [37Pa]) on medium speed and rated airflow at a higher static (0.4 to 0.5 in. w.g. [100 to 125 Pa]) on high speed for applications where higher static is required. Low speed will deliver approximately 85% of rated airflow at 0.10 in. w.g. [25 Pa].

Figure 16: HT Single Phase Line Voltage

Field Wiring

Unit Power Supply

(see electrical table for wire

and breaker size)

Special Note for AHRI Testing: To achieve rated airflow for AHRI testing purposes on all PSC products, it is necessary to change the fan speed to “HI” speed. When the heat pump has experienced less than 100 operational hours and the coil has not had sufficient time to be “seasoned”, it is necessary to clean the coil with a mild surfactant such as Calgon to remove the oils left by manufacturing processes and enable the condensate to properly “sheet” off of the coil.

Figure 17: PSC Motor Speed Selection

Connect the blue wire to:

H for High speed fan

M for Medium speed fan

L for Low speed fan

Medium is factory setting

Fan Motor

HWG Wiring (Split Units Only)

The hot water generator pump power wiring is disabled at the factory to prevent operating the HWG pump “dry.” After all HWG piping is completed and air purged from the water piping, the pump power wires should be applied to terminals on the HWG power block PB2 as shown in the unit wiring diagram. This connection can also serve as a HWG disable when servicing the unit.

20