Installation, Operation & Maintenance | HTV/HTD/HTH SERIES | Heat Controller, Inc. |

CXM Controls

CXM Control

For detailed control information, see CXM Application, Operation and Maintenance (AOM) manual (part #97B0003N12).

Field Selectable Inputs

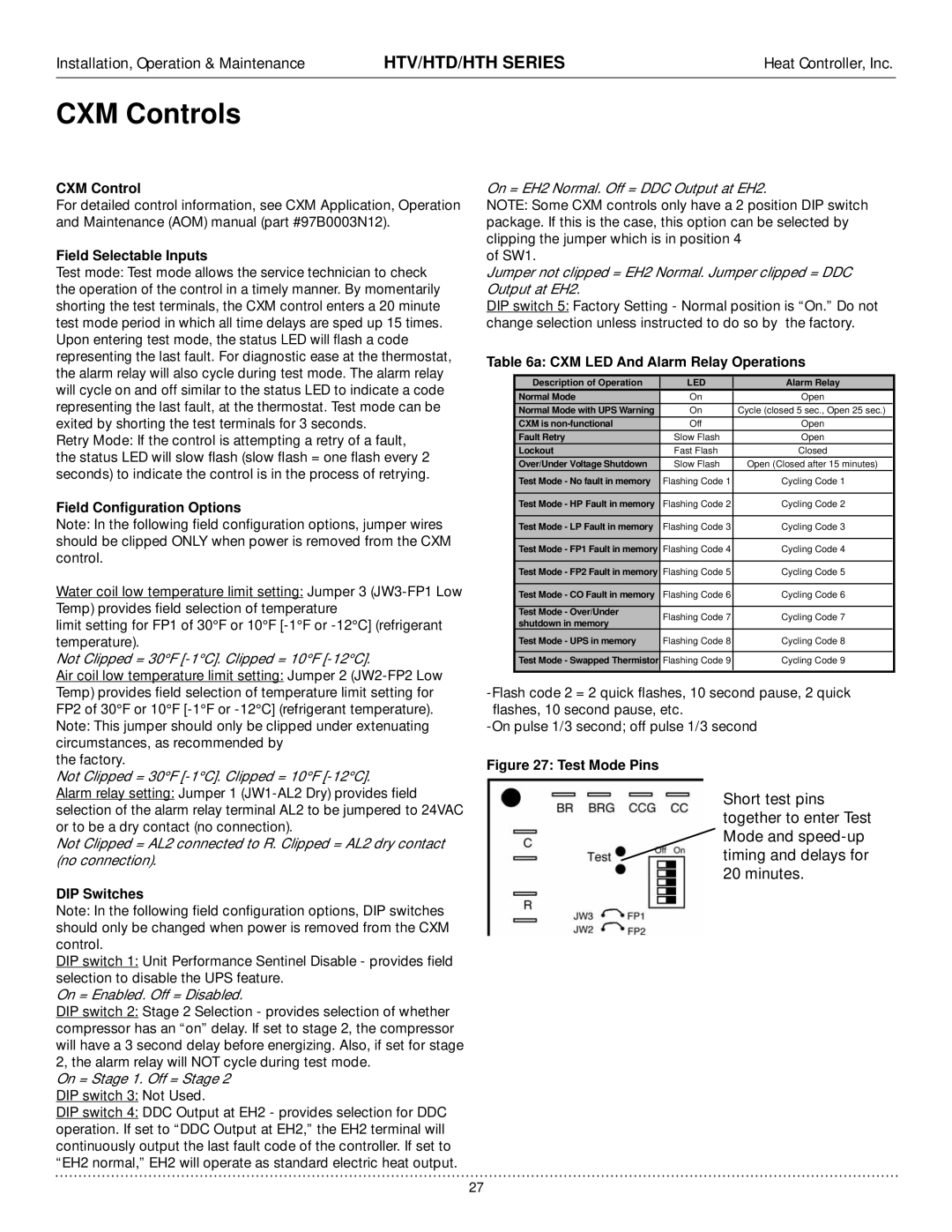

Test mode: Test mode allows the service technician to check the operation of the control in a timely manner. By momentarily shorting the test terminals, the CXM control enters a 20 minute test mode period in which all time delays are sped up 15 times. Upon entering test mode, the status LED will flash a code representing the last fault. For diagnostic ease at the thermostat, the alarm relay will also cycle during test mode. The alarm relay will cycle on and off similar to the status LED to indicate a code representing the last fault, at the thermostat. Test mode can be exited by shorting the test terminals for 3 seconds.

Retry Mode: If the control is attempting a retry of a fault, the status LED will slow flash (slow flash = one flash every 2 seconds) to indicate the control is in the process of retrying.

Field Configuration Options

Note: In the following field configuration options, jumper wires should be clipped ONLY when power is removed from the CXM control.

Water coil low temperature limit setting: Jumper 3

limit setting for FP1 of 30°F or 10°F

Not Clipped = 30°F [-1°C]. Clipped = 10°F [-12°C].

Air coil low temperature limit setting: Jumper 2

the factory.

Not Clipped = 30°F

Alarm relay setting: Jumper 1

Not Clipped = AL2 connected to R. Clipped = AL2 dry contact (no connection).

DIP Switches

Note: In the following field configuration options, DIP switches should only be changed when power is removed from the CXM control.

DIP switch 1: Unit Performance Sentinel Disable - provides field selection to disable the UPS feature.

On = Enabled. Off = Disabled.

DIP switch 2: Stage 2 Selection - provides selection of whether compressor has an “on” delay. If set to stage 2, the compressor will have a 3 second delay before energizing. Also, if set for stage 2, the alarm relay will NOT cycle during test mode.

On = Stage 1. Off = Stage 2

DIP switch 3: Not Used.

DIP switch 4: DDC Output at EH2 - provides selection for DDC operation. If set to “DDC Output at EH2,” the EH2 terminal will continuously output the last fault code of the controller. If set to “EH2 normal,” EH2 will operate as standard electric heat output.

On = EH2 Normal. Off = DDC Output at EH2.

NOTE: Some CXM controls only have a 2 position DIP switch package. If this is the case, this option can be selected by clipping the jumper which is in position 4

of SW1.

Jumper not clipped = EH2 Normal. Jumper clipped = DDC Output at EH2.

DIP switch 5: Factory Setting - Normal position is “On.” Do not change selection unless instructed to do so by the factory.

Table 6a: CXM LED And Alarm Relay Operations

Description of Operation | LED | Alarm Relay | |

Normal Mode | On | Open | |

Normal Mode with UPS Warning | On | Cycle (closed 5 sec., Open 25 sec.) | |

CXM is | Off | Open | |

Fault Retry | Slow Flash | Open | |

Lockout | Fast Flash | Closed | |

Over/Under Voltage Shutdown | Slow Flash | Open (Closed after 15 minutes) | |

Test Mode - No fault in memory | Flashing Code 1 | Cycling Code 1 | |

|

|

| |

Test Mode - HP Fault in memory | Flashing Code 2 | Cycling Code 2 | |

|

|

| |

Test Mode - LP Fault in memory | Flashing Code 3 | Cycling Code 3 | |

|

|

| |

Test Mode - FP1 Fault in memory | Flashing Code 4 | Cycling Code 4 | |

|

|

| |

Test Mode - FP2 Fault in memory | Flashing Code 5 | Cycling Code 5 | |

|

|

| |

Test Mode - CO Fault in memory | Flashing Code 6 | Cycling Code 6 | |

|

|

| |

Test Mode - Over/Under | Flashing Code 7 | Cycling Code 7 | |

shutdown in memory | |||

|

| ||

Test Mode - UPS in memory | Flashing Code 8 | Cycling Code 8 | |

|

|

| |

Test Mode - Swapped Thermistor | Flashing Code 9 | Cycling Code 9 | |

|

|

|

Figure 27: Test Mode Pins

Short test pins together to enter Test Mode and

27