3. Checking of insulation distance

Do not remove too much of the insulation coating at the internal wire connection. Take care not to let the core of the internal wire stick out the Connector 50092 [168] or let the internal wires get caught in a joint between the Housing Ass’y [155] and the Handle Cover [164].

4. No-load current

After

Voltage | 110 V, 120 V | 220 V, 230 V, 240 V |

4.7 A max. | 2.5 A max. |

5. Reassembly requiring adjustment

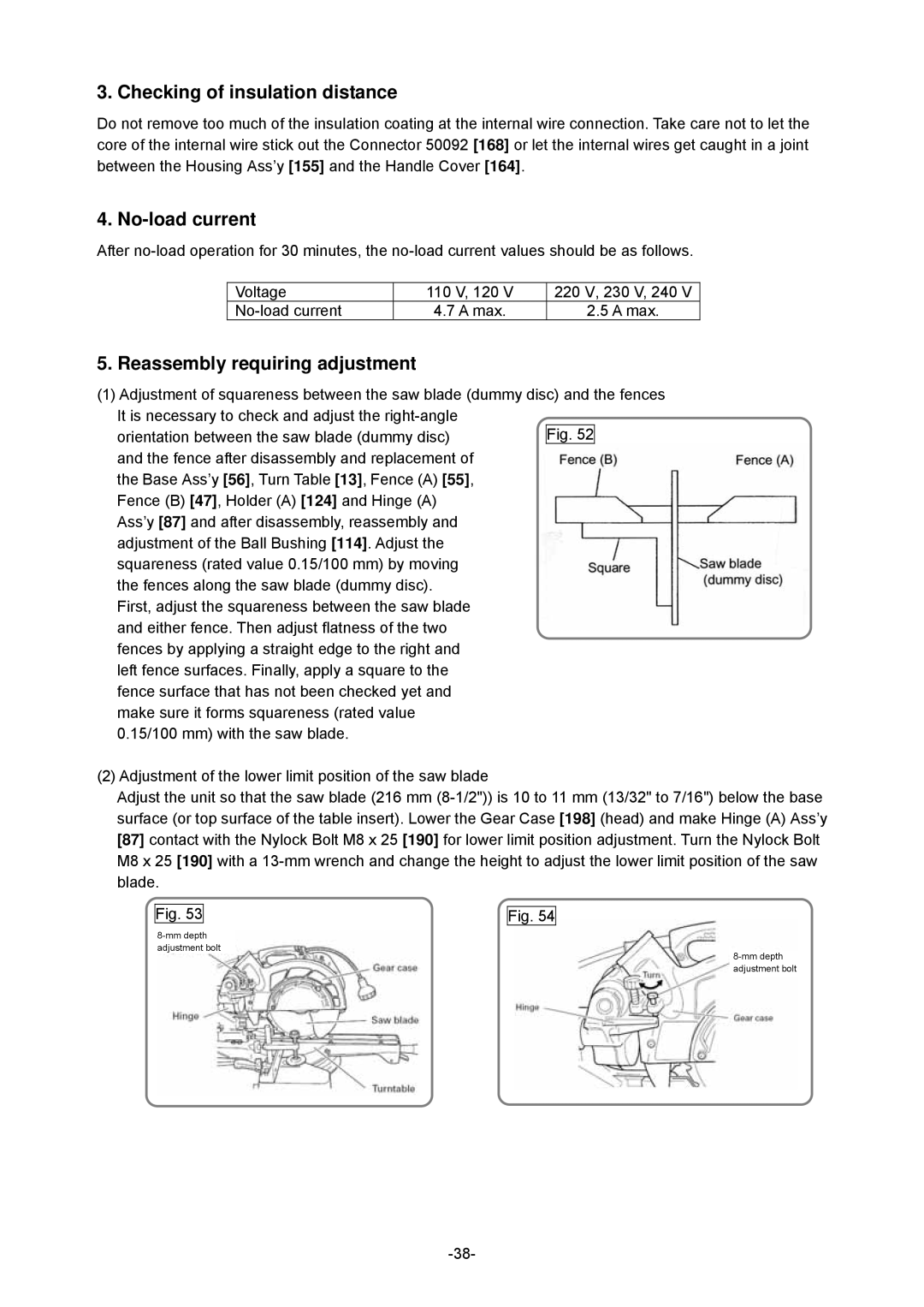

(1) Adjustment of squareness between the saw blade (dummy disc) and the fences It is necessary to check and adjust the

orientation between the saw blade (dummy disc) and the fence after disassembly and replacement of

the Base Ass’y [56], Turn Table [13], Fence (A) [55], Fence (B) [47], Holder (A) [124] and Hinge (A) Ass’y [87] and after disassembly, reassembly and adjustment of the Ball Bushing [114]. Adjust the squareness (rated value 0.15/100 mm) by moving the fences along the saw blade (dummy disc). First, adjust the squareness between the saw blade and either fence. Then adjust flatness of the two fences by applying a straight edge to the right and left fence surfaces. Finally, apply a square to the fence surface that has not been checked yet and make sure it forms squareness (rated value 0.15/100 mm) with the saw blade.

(2) Adjustment of the lower limit position of the saw blade

Adjust the unit so that the saw blade (216 mm

[87]contact with the Nylock Bolt M8 x 25 [190] for lower limit position adjustment. Turn the Nylock Bolt M8 x 25 [190] with a

Fig. 53

Fig. 54